Multi-plate clutch | Design, selection and innovations

- Details

- Hits: 14699

Find out from Mayr how you can Disk clutch for Predictive Maintenance get fit. Ringspann shows how to properly design and select it to optimize the efficiency and performance of your machines. With current tips and completely new coupling systems like this Steel plate clutch from KTR you secure a technical advantage. The article with numerous innovations also answers questions about switchable, torsionally rigid shaft couplings.

Contents

- Torque measuring multi-plate clutch with integrated sensor

- The multi-plate clutch and its industrial applications

- Backlash-free and torsionally rigid steel disc coupling for servo drives

- Correct design and selection of a multi-plate clutch

- All-steel disc clutch with up to 2.000.000 Nm

- FAQ

Torque measuring multi-plate clutch with integrated sensor

18.03.2024 | Mayr Antriebstechnik presented on the Hannover Messe 2024 smart clutches like the new multi-plate clutch made of steel Roba drive checker, which can transmit more than torque and compensate for shaft misalignment. Rather, they offer users the chance to get to know their processes in detail.

18.03.2024 | Mayr Antriebstechnik presented on the Hannover Messe 2024 smart clutches like the new multi-plate clutch made of steel Roba drive checker, which can transmit more than torque and compensate for shaft misalignment. Rather, they offer users the chance to get to know their processes in detail.

The multi-plate clutch and its industrial applications

11.11.2021 | the Disk clutch Diskflex is suitable for a wide variety of applications: from dynamic handling tasks to installation in multi-axis systems through to metal forming systems and the high-temperature environment. Orbit Drive Technology offers an extensive program tailored to the application.

11.11.2021 | the Disk clutch Diskflex is suitable for a wide variety of applications: from dynamic handling tasks to installation in multi-axis systems through to metal forming systems and the high-temperature environment. Orbit Drive Technology offers an extensive program tailored to the application.

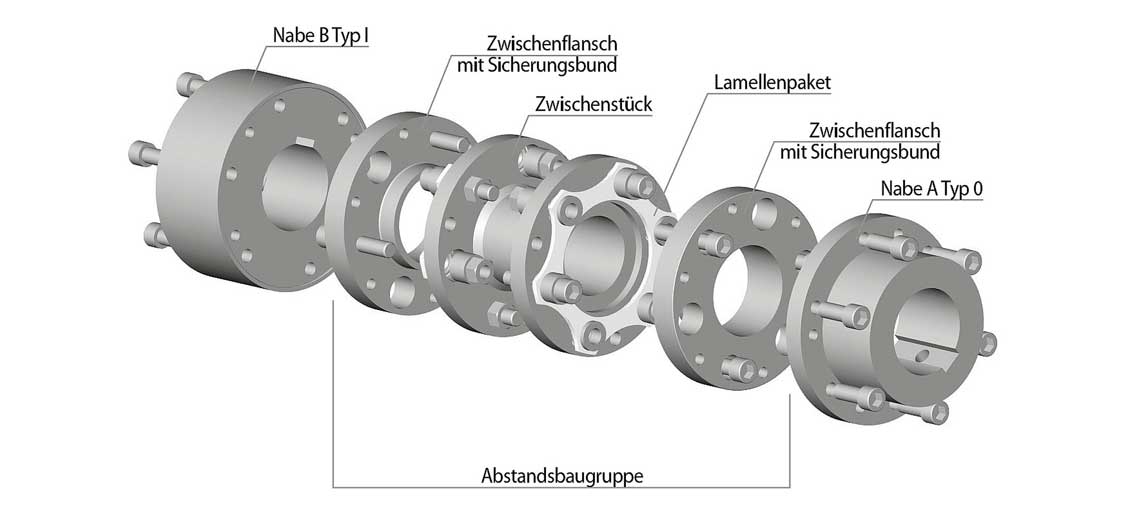

Backlash-free and torsionally rigid steel disc coupling for servo drives

July 30.07.2021, XNUMX | KTR Systems has one Steelmulti-disk clutch Developed for servo drives in the higher power range. The backlash-free and torsionally stiff design Radex NC High Torque reaches speeds of up to 27.500 rpm-1 and transmits torques up to 2000 Nm. Typical applications of the slats Couplings are play-free worm gear with small gear ratios in machine tools, Automation, Medical Technology as well as the Measurement Technology.

Reading tip: Compensating couplings for high temperatures

Reading tip: Compensating couplings for high temperatures

In comparison to the standard series of the same name, the Radex NC High Torque the connection between the lamellas and the hubs is non-positive and positive. This enables use in servo drives in the higher performance range. Its torsionally stiff and flexible lamellae are made of stainless steel, the hubs are made of high-strength aluminum.

Steel lamina coupling with low mass moment of inertia

The steel disk clutches are light, compact and achieve a low mass moment of inertia. They are available in single gimbal and double gimbal designs. For the Shaft hub connection There are two backlash-free versions. These transmit torques from 2,5 to 2000 Nm, speeds from 6500 to 27.500 rpm and temperatures up to +200° C are possible.

Single-joint cardanic coupling

- The Backlash-free servo lamellar clutch Radex NC EK is a single cardanic single-joint coupling for use in servo technology. The simple gimbal design offers angular torque transmission and high torsional spring rigidity.

- The Radex NC EK is about Clamping hubs mounted and is therefore easy to assemble. The hubs are fixed on the shaft by tightening an eccentrically arranged clamping screw. Frictional connections without a keyway and positive connections with a keyway are available.

- The Radex NC EK with Clamping ring hub is a series for high speeds. Two-piece, rotationally symmetrical cone hubs offer smooth running and a secure, frictional shaft-hub connection.

Double cardanic two-joint coupling

The Radex NC DK High Torque from KTR is one double cardanic servo lamina coupling. Their design allows torque to be transmitted at the correct angle while compensating for axial, radial and angular misalignment.

The Radex NC DK High Torque from KTR is one double cardanic servo lamina coupling. Their design allows torque to be transmitted at the correct angle while compensating for axial, radial and angular misalignment.- The Radex NC DK with Clamping hubs is a standard version with an intermediate piece. Thanks to the clamping hubs, the coupling is easy to assemble. The hubs are fixed on the shaft by tightening an eccentrically arranged clamping screw. Frictional connections without a keyway and positive connections with a keyway are possible.

- The Radex NC DK with Clamping ring hubs is a series with an adapter for high speeds. The two-part, rotationally symmetrical conical hubs offer extremely smooth running and a secure, frictionally engaged shaft-hub connection.

Correct design and selection of a multi-plate clutch

March 03.03.2020, XNUMX | The multi-disc clutch is currently particularly popular among designers and developers of industrial drive technology a growing demand against the background of the product offensive of Ringspann, In the area of Couplings This has led to the inclusion of numerous new coupling items in the portfolio.

With the range of 22 series of shaft couplings with nominal torques from 2 to 1.299.500 Nm and almost all technically relevant types, Ringspann currently offers a large selection of couplings Compensation of axial, radial and angular displacements. The company thus offers the designers and engineers of the plant manufacturers a great deal of freedom for the implementation of rigid, rotating rigid or torsionally elastic connections between shaft, Transmission, Motor and machine.

Slip clutch + overload clutch limit torques

Slip clutch + overload clutch limit torques

"In our discussions with customers, we repeatedly notice that there are uncertainties regarding the optimal applications of the multi-plate clutch," comments Martin Schneweis, product manager at Ringspann GmbH in Bad Homburg. "Based on our decades of project experience and our design expertise, we can point out important decision criteria to users and clarify many open questions."

Torsionally rigid and wear-free plate clutches

The multi-plate clutches of the three series RDL ... DSx are wear-free and torsionally rigid Couplings. They are light, do not require lubrication and are suitable for both uniform and variable torquee as well as rough operation with impact and jerky loads. Their construction is designed for backlash-free torque transmission.

The multi-plate clutches of the three series RDL ... DSx are wear-free and torsionally rigid Couplings. They are light, do not require lubrication and are suitable for both uniform and variable torquee as well as rough operation with impact and jerky loads. Their construction is designed for backlash-free torque transmission.

These shaft couplings are available in three versions: with a one-sided plate pack (RDL ... DSO), with a two-sided plate pack (RDL ... DSZ) and with a two-sided plate pack (RDL ... DSA) in a special design according to the requirements of the API 610 (ISO 13709) standard ).

From the API 610 and the associated API 671 (EN ISO 10441) of the American Petroleum Institute There are numerous technical changes compared to the standard version for the demanding use of multi-plate clutches in international natural gas, oil and petrochemicals.

For all manufacturers and suppliers of units and systems for the extraction, production, refining and further processing of petroleum, gas and chemicals, the use of API-compliant shaft couplings is essential and relevant to the competition.

Service factor of the multi-plate clutch

For the selection and design of multi-plate clutches, there is the industry-specific criterion of API Compliance a number of technical-constructive aspects with overarching importance for all areas of application. Regardless of where it is to be used, the correct determination of the nominal torque and operating speed is fundamentally important as well as the consideration of the shaft diameter or shaft displacement.

“Selecting the right one is also important Operating factor. When selecting multi-disc clutches, the torque peaks are taken into account that can occur during practical operation of the clutch, but cannot be precisely calculated in advance," says Mr. Schneweis. The correct operating factor therefore has a decisive influence on the reliability and price of a multi-disc clutch.

Product quality and finishing of the multi-plate clutch

In addition to the technical and physical basics, product quality and finishing must also be considered when choosing the right shaft coupling. Ringspann's multi-plate clutches have surface phosphating for a high standard Corrosion Protection, In addition, the couplings are balanced in quality G6.3 according to DIN 1940. In this way they support vibration-free rotation of the shafts.

"Often this is Quality Score not taken into account when selecting multi-plate clutches. In the application, this leads to concentricity problems, excessive noise emissions and often premature failure of the coupling or even damage to other components of the drive“, Emphasizes the product manager.

The current ringspann portfolio of shaft couplings includes a large selection of flange, compensating and cone clamping couplings as well as toothed couplings, steel band couplings, bolt couplings, claw couplings and even multi-plate couplings.

All-steel disc clutches with up to 2.000.000 Nm

June 13.06.2019, 2017 | Flender completes the one presented in XNUMX N-Arpex coupling and has two further expansion stages with eight and ten Glandpoints in. As a result, the coupling series covers a diameter of up to 988 mm and a torque of up to 2.000.000 Nm. Thanks to the compact design and an increased bore capacity, a jump in size is also possible.

June 13.06.2019, 2017 | Flender completes the one presented in XNUMX N-Arpex coupling and has two further expansion stages with eight and ten Glandpoints in. As a result, the coupling series covers a diameter of up to 988 mm and a torque of up to 2.000.000 Nm. Thanks to the compact design and an increased bore capacity, a jump in size is also possible.

A smaller clutch transmits more torque compared to the previous Arpex model. The torsionally rigid one All-steel multi-plate clutch is suitable, among other things, for driving pumps, fans, compressorsen, generators, turbines and paper and printing machines.

Cone screw connection for the plate packs

A new, more compact Flender Cone screw connection for the disk packs enables easy and quick assembly of the couplings, especially in the high torque range. It increases the power density of the N-Arpex series. The revised component design introduced in 2017 with the ARN-6 variant already ensured an improved ratio of torque and material usage with its compact design and increased bore capacity.

With the two new N-Arpex multi-disc clutches, Flender offers one Construction kit one that increases the number of available variants and at the same time reduces the number of components. The three standard series of the predecessor Arpex merge into one series with the N-Arpex.

Articulated coupling for bridging high shaft misalignments

Articulated coupling for bridging high shaft misalignments

The new series are also for one explosive environment designed in accordance with Directive 2014/34/EU and meet the requirements of API610/ISO 13709 and API671/ISO 10441. N-Arpex all-steel couplings are designed as standard for low temperatures of up to -50 °C. With the coupling made entirely of steel, the torque transmission and simultaneous offset compensation between the machines to be connected are play-free, torsionally rigid and flexible. The offset compensation can take place in axial, angular and radial directions. The plate packs of the N-Arpex couplings are made of stainless spring steel, are not subject to wear and are therefore maintenance-free.

FAQ

How does a multi-plate clutch work?

A multi-plate clutch has the function of providing torque through friction transferred to. This takes place between several thin disks, the so-called slats, which are alternately connected to the drive shaft and the part to be driven. When the clutch is activated, these plates are compressed by an axial force, creating friction and transferring the rotational motion from the drive shaft to the coupled part. When deactivated, power is removed, the fins separate, and transmission is interrupted.

Where are multi-plate clutches used?

Multi-disc clutches are used in applications in which a reliable and precise torque transmission is required, for example in vehicle transmissions, in mechanical engineering, drive systems for wind turbines and in heavy industry. Here they create the basis for a smooth start and contribute to load regulation.

Can a multi-plate clutch be switched?

Ja, a multi-plate clutch is switchable; it can be operated to separate or connect the connection between the drive train and the output unit.

Source: This article is based on information from the following companies: Flender, KTR Systems, Mayr Antriebstechnik, Orbit Antriebstechnik, Ringspann.

You might also be interested in...

Disc brake | with fixed caliper brake + floating caliper brake

High-performance brake wind turbine with monitoring

clamping technology | Intelligent, safe, efficient!

Robco robot kit with safety brake from the construction kit

Safety brakes: innovations + tips for installation

The Radex NC DK High Torque from KTR is one double cardanic servo lamina coupling. Their design allows torque to be transmitted at the correct angle while compensating for axial, radial and angular misalignment.

The Radex NC DK High Torque from KTR is one double cardanic servo lamina coupling. Their design allows torque to be transmitted at the correct angle while compensating for axial, radial and angular misalignment.