for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Transmission enable the precise transmission of torque and speed and are therefore essential components for drives in industry and others Industries. There are now many different types, all of which have to have one thing in common to make the drive train competitive in the Industry 4.0 system: efficiency, sustainability and intelligence. We provide you with current information here Developments, technologies and Areas of application before, offer insights into Engineering the future and provide further comprehensive knowledge on the topic.

Modern transmission developments focus on improving Efficiency and precision. The designers also focus on optimizing materials, advanced lubricants and digital monitoring systems. High-strength alloys and modern manufacturing processes enable a compact design while simultaneously increasing torque and load capacity.

Integrated ones are also revolutionizing sensors and Condition monitoring-Systems the way gears are operated in industrial applications. By recording e.g. Using real-time data such as temperature, vibration and torque, predictive maintenance strategies can be developed that minimize downtime and maximize uptime.

Trends such as networking through Industrial IoT and condition monitoring promote the use of intelligent gears that provide real-time status data. In addition, will modulate Gear systems are becoming increasingly popular because they allow easy adaptation to various applications and thus enable flexible integration into production systems. The following new products focus on these development trends:

Planetary gearboxes, spur gearboxes, bevel gearboxes, worm gearboxes, hollow shaft gearboxes, solid shaft gearboxes, angular gearboxes, wave gearboxes, rack and pinion gearboxes, manual gearboxes, industrial gearboxes, chain gearboxes, friction gearboxes, rolling element gearboxes, belt gearboxes, differential gearboxes, bevel-helical gearboxes, automatic gearboxes, cam gearboxes, automatic gearboxes, crank gearboxes, roller gearboxes, cycloidal gearboxes, screw gearboxes, toothed belt gearboxes , gear transmissions, hydraulic transmissions, electrical transmissions, spindle drives, coupling gears, stepper transmissions, geared motors, extruder gears, turbo gears, axle gears, special gears, magnetic gears, hypoid gears, harmonic drive gears, eccentric gears, precision gears, mechanical gears, hydrostatic gears, friction wheel gears, traction gears,… .

There are certainly even more types of transmissions, which can be classified according to various criteria: These include axle arrangement, power transmission, design or number of gear ratios. We will introduce you to the most important industrial gearboxes below:

coming soon...

The compact design, low-noise operation, the ability to transmit high torques, energy efficiency with high efficiencies and much more characterize them planetary gear out. Due to their high torsional rigidity, the arrangement of the Gears also for very good stability. Here we present new developments for industrial applications.

A pair of worm gear is characterized by its ability to achieve high torque transmission in a compact design. It finds Application in elevators, conveyor systems or in automation technology where low-noise operation and self-locking are required. Modern worm gears are efficient, durable and optimized for precise control tasks. In this article you will discover some of these gearboxes from various manufacturers.

The Ball Screw converts a rotational movement into a longitudinal movement. It causes less friction than others Linear Drives, like the trapezoidal thread spindle. It offers high efficiency, which means a longer service life. The specialists will tell you how these properties can be exceeded in detail.

In certain applications are Lead Screws an extremely economical alternative to the more precise ones ball screws. Dr. Tretter has included them in its broad product portfolio and covers a very wide range of diameters and pitches with the trapezoidal thread spindles.

The simply constructed ones Spur gears offer high efficiency and can effectively transmit torque between parallel shafts with minimal noise. This makes them suitable for use in manufacturing plants Automotive drives to wind turbines and other heavy industrial applications. This article highlights innovative New developments, applications and shows comprehensive Serviceservices.

Wave gears are suitable for applications that require precise positioning and high repeatability. The simple but effective Gears are used in all areas of drive technology and are particularly common in the robotics used. The wave gear offers, among other things, high efficiencies and torque capacity.

The Angle gear transmit torque efficiently between crossing shafts, making them suitable for complex drive systems in the Automotive industry, in mechanical engineering or in aviation makes it particularly valuable. Find out more about the latest developments from various manufacturers and the versatile application possibilities of angle gears, especially from Bevel gears.

Systems for positioning tasks in mechanical engineering and in the Food industry withstand harsh environmental conditions. They can withstand such extremely high loads Rack gear stood easily. The rack and pinion drives from this provider are available in numerous lifting systems, handling components and positioning systems in use worldwide. The following product information is dedicated to the new developments.

Discover the latest developments in the world of Drive and conveyor chains. This article provides information about innovative new products, shows their efficiency using user examples from the wood industry and automobile construction, and presents you with exclusive service offers. Learn how to be eco-friendly roller chains Optimize your production processes in every industry and so on Reduce TCO costs.

The Difference The difference between the two most commonly used bearing types, plain bearings, including bushings, and rolling bearings such as ball bearings, roller bearings or needle bearings is as follows: With plain bearings, the parts that move relative to one another are in direct contact. In rolling bearings there are rolling elements between the inner ring and outer ring Frictional resistance and thus reduce wear.

Gears play a central role in Industrial driven, which are used in a variety of machines and systems. Such a Gear must withstand extreme stress, is typically corrosion resistant, and is often designed to be self-lubricating for longer life and reduced maintenance.

The Timing belts is a universally applicable drive element for many industrial sectors such as automotive, packaging technology, mechanical engineering, tool making, printing technology, textile engineering. The latest new development is the Breco timing belt from Mulco, which comes with a new coating material can handle extremely hot temperatures.

An rack converts rotating movements in the rack drive into linear ones. It is suitable for applications in automation technology, in car steering or is used in CNC machines. Modern racks are very precise and robust against environmental influences.

A complete virtual image of drive trains and gearboxes is only possible if gearbox, rolling bearing and gearing specialists simulation models digitally link with each other. Therefore, the cross-company and cross-system data exchange is one of the most important prerequisites for the generation of Digital Twins. Schaeffler and SEW have created such a data exchange.

With the free Motor gear configurator Users can directly select the most cost- and energy-efficient motor configuration transmission design for your application. The proven Neugart calculation program (NCP) is available as a user-friendly configuration tool.

GWJ Technology releases a new and expanded version of its software Transmissioncalculation for complete Geartransmission in front. The new version of the system manager as an extension of the standard solution Eassistant and TBK now also calculates shaft geometries of gears with the support of background graphics.

In vehicles, the transmission from the steering wheel to the steering The wheels are often carried out by a pinion rack drive. With the ZE7 module, Kisssoft has an option Screw wheel with rack Calculation integrated.

GWJ Technology offers software for the gear calculation in transmission and mechanical engineering. The calculation professional from Braunschweig supports designers and development engineers in their daily work. Here you will find further developments of the web-based calculation software eAssistant and the transmission software TBK.

The transmission portfolio from Igus includes a wide range of lubrication-free and low-maintenance solutions, including robotic gearboxes, Drygear shaft gearboxes and transmission systems for delta robots. These gearboxes are specifically designed for use in automated applications and are characterized by their high precision, reliability and longevity. Thanks to the use of high-quality, self-lubricating plastics, they enable high resilience with minimal maintenance effort and offer a cost-effective alternative to conventional gears.

In logistics, care, kitchens, bars or in the fields: the potential for service robotics is great. Cobots take on monotonous and non-ergonomic tasks. Igus provides one for the simple, cost-effective implementation of such lightweight robots Gearbox kit for cobots. The focus is on the fully integrated Tribo strain wave gear with motor, absolute value encoder, force control and controller.

Plastic gears from Igus ensure lubricant-free power transmission in countless applications. Because of its special material Composition of base polymers, fibers, fillers and solid lubricants is a Gear Made from Iglidur high-performance polymers, highly wear-resistant.

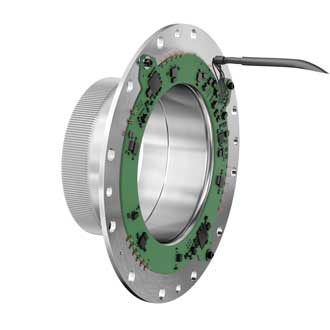

Schaeffler offers a versatile transmission portfolio for industry, which includes tailor-made solutions for different industries. The products range from high-precision planetary gears to bevel and spur gears to drive modules that are specifically tailored to industrial applications. These gearboxes are known for their efficiency, robustness and long service life because Schaeffler uses advanced manufacturing processes and high-quality materials. In addition, Schaeffler supports customers with services such as condition monitoring to ensure predictive maintenance and maximum uptime.

Precision gears have a significant influence on the dynamics, positioning and repeatability or the service life of a construction. Schaeffler effect in the young company Ultra Precision Drives Two types of transmission have been developed that exceed the current state of the art: the Strain wave gear Series RT and the planetary gear the PSC series. Find out how you can use it to take your robotics application to a new level.

From the tiny mini Rolling From a huge rolling bearing measuring several meters to a system solution: The portfolio of Schaeffler ball and roller bearings has solutions for every application - from machine tools, robotics and industrial automation to the food and packaging industry to wind turbines or Mobile work machine, to name just a few.

Tsubaki offers an extensive range of drive elements for industry. The range includes high-quality roller chains, toothed chains, Couplings, slip hubs and conveyor chains. These drive elements are designed to ensure high performance and durability even in demanding environments. By combining advanced technologies and durable materials, Tsubaki actuators deliver efficient, low-maintenance solutions that support optimal uptime and reduced downtime in industrial facilities.

Discover the latest developments from Tsubaki in the world of Drive and conveyor chains. This article provides information about innovative new products, shows their efficiency using user examples from the wood industry and automotive engineering, and presents you with exclusive service offers. Learn how to be eco-friendly roller chains Optimize your production processes in every industry and so on Reduce TCO costs.

In their function as drive chains or conveyor chains in industry, roller chains are often referred to as machine element perceived as a means to an end, while the more complex components surrounding them receive greater attention. And so designers often use cost-effective standard solutions and don't even question them custom Development. Learn how from Tsubaki Find the optimal chain for your specific requirements.

Other manufacturers are (ordered alphabetically):

A gear is a mechanical system used to transmit and convert torque and speed. It consists of interlocking gears or other power-transmitting components that transfer kinetic energy from the drive to the output. Gearboxes can reduce or increase speeds while adjusting torque accordingly.

Gears fulfill four basic tasks in technical systems:

Gearboxes can be divided according to various criteria, depending on their design, function or area of application. They are divided according to Type, translationrelationship, Axle arrangement or Applicationarea.

The gearbox in vehicles adjusts the speed and torque of the engine to the respective driving situation by varying the gear ratio between the engine and drive wheels. At low speeds or on steep inclines, the transmission ensures that higher torque is available. At higher speeds, it reduces engine speed to drive more efficiently and reduce fuel consumption. Additionally, it enables reversing and, in combination with the clutch, interrupts the power transmission so that the driver can smoothly switch between gears in the transmission.