More than 50 years of functional safety to meet SIL

- Details

- Hits: 5607

A little security is enough Pepperl + Fuchs not and the automator leaves nothing to chance. The pioneer has been developing and manufacturing safety-related devices for over half a century. Here you will find functional safety for the factory Automation and process automation from product to training:

Contents

- 50 Years of Functional Safety – Video

- SIL Roadshow for functional safety in a new guise

- Inductive safety sensor portfolio according to the Machinery Directive PLd

- Absolute positioning according to SIL3 / PL e with only one sensor

- Industry 4.0 and cyber security in the focus of the 10th SIL consultation hour

- SIL consultation hour: Security vs SIL

50 Years of Functional Safety – Video

04.05.2022 | above 10.000.000 units sold under 750 security products is recorded by Pepperl+Fuchs in 2022. This means that the company has one of the largest security portfolios on the market.

SIL Roadshow for functional safety in a new guise

02.03.2020 | Functional safety is an important topic in industrial automation, which the SIL roadshow dedicated for years. A consortium of experts from the companies Ramsys, Pepperl+Fuchs, Samson, Hima, Endress+Hauser and TÜV SÜD Industrie Service GmbH has Functional safety workout 2020 set up a new format.

Using a typical case study, the participants develop one together with the experts from the field safety device. All functional safety phases of the safety lifecycle are addressed, from risk analysis and implementation to operation, maintenance, modification and decommissioning of systems. The newly published standards and regulations for functional safety IEC 61508, IEC 61511, VDI / VDE 2180, NA 106, etc.

Standard for location technology with UWB, RFID, 5G, GPS

Standard for location technology with UWB, RFID, 5G, GPS

In the three workshops on functional safety, introductory keynote speeches provide an overview of the requirements for safety functions from the various standards and regulations. With the help of specific exercises in small groups, the SIL functional safety is applied and deepened in a practical manner.

Appointments SIL Road Show 2020:

- March 3, Neuhofen ad Ybbs (Austria)

- May 6, Dresden

- July 1, Speyer

- September 30, Pulheim (near Cologne)

The participation fee for the SIL Functional Safety Workshop is €330. the Participant places are limited.

Inductive safety sensor portfolio according to Machinery Directive PLd

28.05.2019/XNUMX/XNUMX | The new Safety sensor family from Pepperl+Fuchs includes four cylindrical and cuboid series Cables- And Plugconnection. The sensors are TÜV certified according to the Machinery Directive standard EN 13849, Performance Level PLd, Category 2 and SIL2. Applications are safeguarding of machines and system parts as well as safe position detection in this environment.

28.05.2019/XNUMX/XNUMX | The new Safety sensor family from Pepperl+Fuchs includes four cylindrical and cuboid series Cables- And Plugconnection. The sensors are TÜV certified according to the Machinery Directive standard EN 13849, Performance Level PLd, Category 2 and SIL2. Applications are safeguarding of machines and system parts as well as safe position detection in this environment.

Inductive sensors with increased temperature range and increased EMC strength and E1 approval for the use of mobile machines and vehicles in safety-critical areas round off this new portfolio.

This security proximity switch do not require a special coded target, allowing them to be used with standard metal actuators. The sensors also have no blind zone and can therefore be installed easily and without additional adjustment. For connection to a safety module or a corresponding controller, the Sensors via standardized OSSD outputs (“Output Signal Switching Device”) for signal and diagnostics.

Due to the electronics used, the inductive safety sensors have very high security values. This means that the regularly required functional tests are much less frequent. It also significantly simplifies electronic integration into the safety loop.

Absolute positioning according to SIL3 / PL e with only one sensor

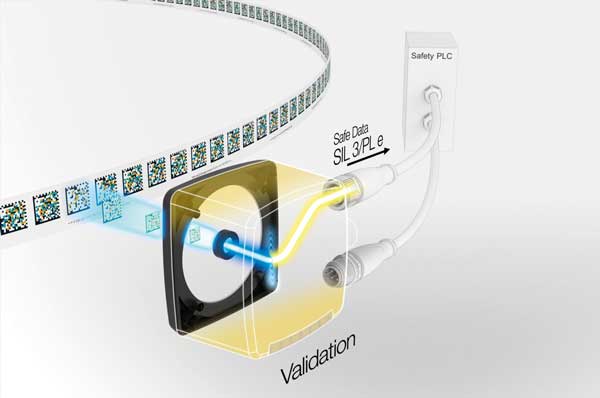

18.03.2019/XNUMX/XNUMX | Pepperl+Fuchs is presenting with Safe PXV the new generation of positioning systems: For the first time, it enables safe absolute positioning according to SIL 3/PL e with just one sensor. The possible applications and opportunities are diverse – not least in the Automobile-Production.

18.03.2019/XNUMX/XNUMX | Pepperl+Fuchs is presenting with Safe PXV the new generation of positioning systems: For the first time, it enables safe absolute positioning according to SIL 3/PL e with just one sensor. The possible applications and opportunities are diverse – not least in the Automobile-Production.

So far, safe absolute positioning was after SIL 3/PL e hardly feasible for plant operators, as it involved considerable effort and high costs. So far, redundant systems with different sensors or different technology had to be set up. In addition, a plausibility check of the data was carried out in the safe steering necessary and the entire development had to be monitored and finally approved by TÜV.

With the new Safe PXV, all of this is achieved Positioning with just one sensor. The new security technology combines a 2D read head with a three-color data matrix code tape. The system's special code tape contains two superimposed Data Matrix codes in red and blue. The 2D reading head is equipped with two differently colored LED rings – also in red and blue. These are activated separately from each other and then only read out one data matrix code at a time. The result is always a SIL 3/PLe absolute position.

Safety relay for signal processing for machine safety

Safety relay for signal processing for machine safety

The Safe PXV is suitable for the safe absolute positioning of electrified monorail systems (EMS), for stacker cranes in storage and conveyor technology, turntables in mechanical engineering and for elevator construction and for wind turbines in the area Renewable energies. When developing the system, safety and reliability were also important Easy to use of great importance. This makes assembly extremely quick and uncomplicated. The code tape is already supplied in the appropriate length and simply has to be stuck on. The reading head is then only roughly aligned and further parameterization can be carried out directly via the safety controller using the Profinet GSDML file.

Industry 4.0 and cyber security in the focus of the 10th SIL consultation hour

13.11.2018/2013/XNUMX |Since XNUMX, Pepperl+Fuchs has had a certified functional safety management system and is one of the pioneers of functional safety. With its SIL consultation hour in Mannheim, the automation company recently offered its users a dialogue on the main topic "SIL vs. IT security" for the tenth time.

13.11.2018/2013/XNUMX |Since XNUMX, Pepperl+Fuchs has had a certified functional safety management system and is one of the pioneers of functional safety. With its SIL consultation hour in Mannheim, the automation company recently offered its users a dialogue on the main topic "SIL vs. IT security" for the tenth time.

As host and co-organizer of the SIL consultation hour the Mannheim company has more than 40 years of experience in the development of safety-relevant devices. Based on the first safety concepts for switching amplifiers from the 70s, SIL 3 requirements can still be met today. Since then, well over ten million safety-related interface devices have been installed.

Interactive event

With this year's edition of the SIL consultation, Pepperl+Fuchs in Mannheim celebrated an anniversary: already for the tenth time the event took place and continues to enjoy great popularity among practitioners in the field of functional safety. On the one hand, the interactive character of the event contributes to this: Questions can be submitted by the participants before the event. On the other hand, the event always has its finger on the pulse, as the most recent edition SIL vs. IT security showed.

Inductive sensor detects carbon for the first time in the world

Inductive sensor detects carbon for the first time in the world

Specialists from testing organizations such as TÜV, functional safety managers from device manufacturers and safety experts from industry had gathered at the Pepperl+Fuchs headquarters in Mannheim, as well as representatives from authorities and associations, as well as legal experts. With this wide-ranging competence, the participants were once again able to draw on the competent answers to their questions vertrauen.

Headlines of cyber security

"Experts on the Defensive", "Ten Steps Behind the Hackers" - headlines like this are often read when von Cyber Security the speech is. Often the threats are countered by a stronger isolation of the respective system. However, this is countered by the fact that the digitization of automation and thus an ever more comprehensive integration of components and systems is progressing rapidly. The structuring of functional safety and IT security inevitably took up a lot of space during the SIL consultation hour. Ultimately, in terms of standards and law, there are two separate worlds in which the respective manufacturers have to meet their responsibilities with different measures.

Code meter for monetizing embedded software

Code meter for monetizing embedded software

Another much-discussed topic was the legal situation of the manufacturers against the background of Safety vs Security. The following applies to device manufacturers: They are obliged to comply with their duty of care. This means that they have to monitor the market, competition and technical developments and adapt their measures to the current state of the art. Different requirements are placed on the components of the manufacturers than on the pure software providers. While "normal" products need to ensure that these products are "secure", digital service providers need to take appropriate technical and organizational measures to manage risks to the security of network and information systems caused by unauthorized third parties .

Keep liability risks low

The experts present explained that the device manufacturers must use suitable measures to keep their liability risks as low as possible. Unique and comprehensive contractual regulationsn along the entire value and distribution chain as well as an appropriate and proven product monitoring management would play a prominent role. After all, carefully prepared instructions are indispensable for the user. The documents should contain a precise description of the product's intended use and possible uses and, if necessary, a clear reference to the obligation to carry out security updates.

The experts present explained that the device manufacturers must use suitable measures to keep their liability risks as low as possible. Unique and comprehensive contractual regulationsn along the entire value and distribution chain as well as an appropriate and proven product monitoring management would play a prominent role. After all, carefully prepared instructions are indispensable for the user. The documents should contain a precise description of the product's intended use and possible uses and, if necessary, a clear reference to the obligation to carry out security updates.

Most of the participants were opposed to efforts to evaluate mechanical components in the same way as electronic components in the future, since - unlike with complex electronics - with mechanical components the accidental errors are almost insignificant are.

Some participants reported that some manufacturers of actuators and actuators used in PCT protective devices are used are making increasing demands on the operator. For example, the periods of use would be limited or annual functional tests, maintenance after switching cycles or period of use, inspections and repairs would only be required by certified workshops. Restrictions, unless they are normative, are rejected by the majority of the operators.

Legal situation in global plant construction

Regarding the legal situation international projects of plant construction outside the European Union and the USA, several participants submitted questions.

It becomes particularly problematic here if there are neither legal nor contractual requirements for functional safety. Experiences of company representatives showed that at projects in India and Africa in some cases, functional safety should be expressly dispensed with due to alleged additional costs. If this were actually to be done, it would have to be documented. When in doubt, the higher standards should always be used and legal advice from the country concerned should be sought.

dr Andreas Hildebrandt, Head of Training and Committee Work at Pepperl+Fuchs, included these findings in his summary of the event: “The topic of functional safety is becoming more and more complex in times of digitalization and globalization. Technical aspects are accompanied by legal challenges. It is all the more important to offer forums such as the SIL consultation hours, where there is a comprehensive exchange between different disciplines and very specific everyday problems are answered by experts with the necessary depth.”

Functional safety at Pepperl + Fuchs

A total of almost 800 safety products are available to users, including around 300 interface modules alone. They are also supported with free information on the basics and product selection, such as a Safety product selector, a PFD/PFH calculation tool according to EN61508 and VDI/VDE 2180, Sistema libraries as well as a SIL compendium and a SIL poster.

A total of almost 800 safety products are available to users, including around 300 interface modules alone. They are also supported with free information on the basics and product selection, such as a Safety product selector, a PFD/PFH calculation tool according to EN61508 and VDI/VDE 2180, Sistema libraries as well as a SIL compendium and a SIL poster.

On SPS IPC Drives In 2018, Pepperl+Fuchs is presenting new safety relays from the KFD2-RSH family based on a 1oo3 architecture with a diagnostics function. This means that the user does not have to incur any additional effort for proof tests.

All modules are line fault transparent, which means that the field side of the signal circuit is without additional wiringeffort monitored for line errors. This also ensures safe switching on. The relays are immune to test pulses and are therefore compatible with digital output cards of all commercially available controllers. The modules are available for DTS (de-energized-to-safe) and ETS (energized-to-safe) applications as well as for load circuits up to 60 V DC and up to 230 V AC. The single-channel devices are Atex / IEC ex Zone 2 and UL approved and are suitable for applications up to IEC 61508 SIL 3, the DTS modules are also suitable for applications up to EN ISO 13849 PL e.

The author is Andreas Grimsehl, Product Marketing Manager Interface Technology, at Pepperl + Fuchs GmbH.

Look into the event

SIL consultation hour: Security vs SIL

24.09.2018/400/2009 | Since XNUMX, around XNUMX functional safety specialists have attended the "SIL consultation hours" organized by Pepperl+Fuchs and atp-magazine. Under the main theme Security vs. SIL there were keynote speeches covering both technical and legal aspects.

24.09.2018/400/2009 | Since XNUMX, around XNUMX functional safety specialists have attended the "SIL consultation hours" organized by Pepperl+Fuchs and atp-magazine. Under the main theme Security vs. SIL there were keynote speeches covering both technical and legal aspects.

In addition to keynote speeches, the annual event offers guests the opportunity to ask questions to the experts in advance. On September 18th and 19th, the tenth SIl consultation hour took place at the Pepperl+Fuchs headquarters in Mannheim, where specialists from industry, consulting, testing service providers and public administration spoke to the participants speech and answer stood.

The industrial digitization and their effect on safety technology determined the short presentations on the first day of the event. The contributions included both technical and legal side glances in the direction of IT security. Frank Schiller from Beckhoff reported on experiences with functional safety and IT security in automation, as well as Udo Menck (Dow Germany) and Gregor Schmitt Pauksztat (Bayer) from practice when implementing PCT safety devices.

The authorities' view of this topic was Joseph Kuboth set out by the State Agency for Nature, Environment and Consumer Protection NRW. Andreas Harner from the VDE informed the participants about CERT@VDE, an IT security platform that supports SMEs in IT security incidents in the automation industry across organizational boundaries. The legal aspects of safety and IT security were addressed by Dr. Susanne Wende from Noerr LLP in her remarks. Dr. Gunther Kegel from the host Pepperl+Fuchs.

You might also be interested in...

Industrial radar sensor with CAN interface

Artificial Intelligence | trends and developments

RFID and Barcodes | Industrial identification

RFID reader and barcode scanner for identification

battery production | Facts and Technologies