CFD simulation reduces the risk of a Covid-19 infection

- Details

- Hits: 19822

In the course of Corona pandemic will the CFD simulation to optimize existing Safety measures used in a wide variety of facilities. So had Dassault Systèmes with its Simulia software supported the Paris hospital Pitié-Salpêtrière AP-HP in assessing the risk of infection from airborne coronaviruses in several rooms. The assessment of the aerosol distribution in the GEA canteen also led to the safe reopening of the rooms.

Contents

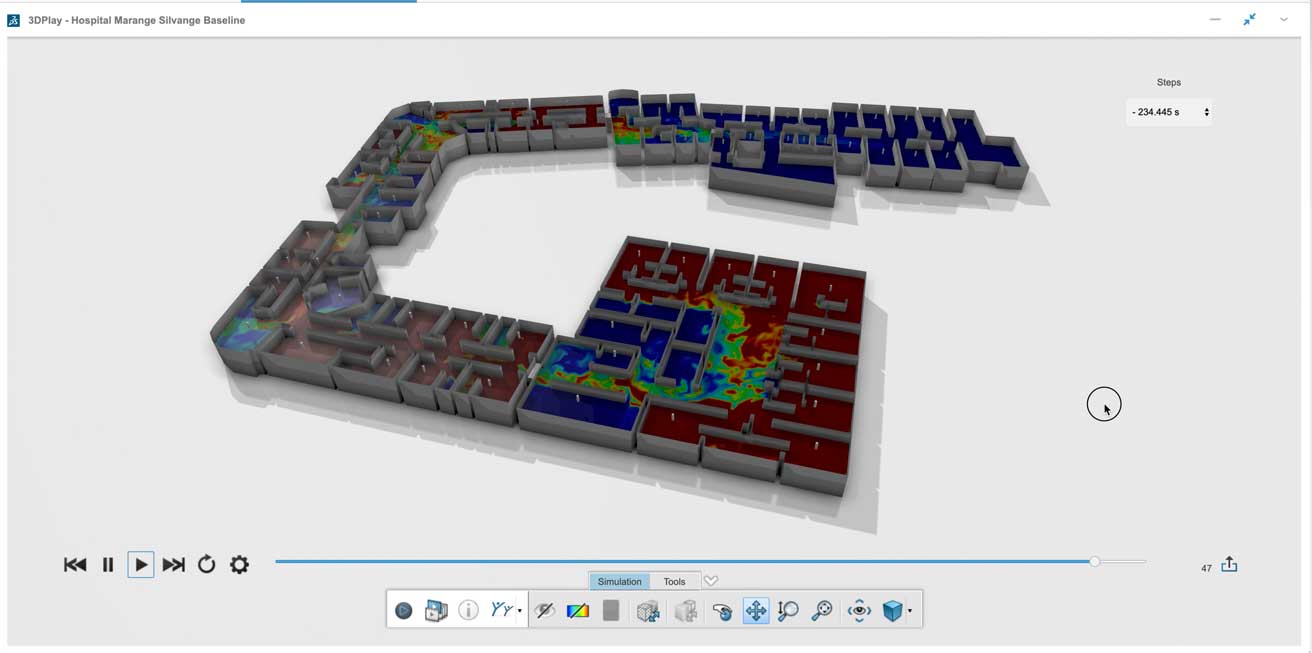

CFD simulation in the hospital

Dassault Systèmes supports that Pitié-Salpêtrière hospital in Paris with the CFD simulation when assessing the risk of a Covid-19 infection. The hospital relies on 3D air flow simulation. In this way, it improves the existing safety measures and reduces the risk of exposure in patient care and in the workplace.

The CFD specialists from Dassault Systèmes founded a project group with the hospital management and the Parisian architect Arnaud Delloye when France announced the second nationwide lockdown in October 2020.

3D simulation software designed by power users

3D simulation software designed by power users

The goal was the planned Remodeling to be assessed in a post-operative monitoring room. Various scenarios were simulated, such as in the event that infected and non-infected people are in this room at the same time. The participants examined possible solutions that could proactively supplement the existing security measures of the hospital. This should reduce the risk of exposure for the uninfected patients and staff.

Simulation of air flow and droplet deposition

With the simulation software simulated the air flow and droplet deposits in the room were modeled and analyzed. Using the CFD simulation, the optimal solution was found in the form of a combination of two components: a partition and a special exhaust fan above each infected patient.

Construction software for lightning-fast product development

Construction software for lightning-fast product development

The architect already had a similar airflow system for one Parisian restaurant designed. In the collaboration, medical professionals, civil engineers and CFD specialists have developed a new scientific approach.

As part of a Funding program from Dassault Systèmes, this project is the latest since the beginning of the pandemic. The Dassault specialists had previously advised another AP-HP hospital in Paris, Bichat - Claude Bernard, on the renovation of a trauma ward. In the course of the pandemic, it was a matter of optimally positioning patient beds, examining surface contamination and installing new air filter systems.

Parallels between the individual projects

In all of these projects, the special circumstances of a department are specifically taken into account in order to identify specific risks and solutions. Also contributions from students of France's leading technical University of Ecole Polytechnique flow into this collective effort. In the coming weeks Dassault will simulate and identify the risks of the virus spread in the canteens of two AP-HP hospitals and recommend measures that reinforce the precautions already in place for hospital staff.

"In our endeavor to minimize the impact of the virus on our fellow citizens and health systems, we must continue to take a proactive approach," he said Claire Biot, Vice President, Life Sciences Industry at Dassault Systèmes. “With our simulations, we can improve safety in hospitals, nursing homes and special clinics and optimize the structural conditions of planned conversions or new buildings. This collaboration is part of our mission to bring product, nature and life into harmony and make the world a better, safer and healthier place. "

CFD simulation in GEA canteen

The canteens of the GEA were closed at all locations in March 2020 due to the corona pandemic. The world's largest system provider is currently using food processing industry a Simulia application which simulates air currents in the staff canteen in Oelde. The CFD simulation the aerosol distribution is based on the 3D Experience software from Dassaul Systems and aims at the safe reopening of the rooms.

“The canteen is a really important place,” says Erich Nitzsche, Vice President Engineering Standards & Services at GEA. “Everyone comes here to chat with colleagues over a meal or an espresso. We had to close and disinfect the canteen. And at the same time the question arises as to how we can open it again without endangering the health of the employees. "

Simulation of the aerosol distribution and digital twin

The coronavirus spreads through Droplets in the ambient air. GEA would like to find out how the aerosol distribution behaves in its own canteen. To do this, the company commissioned Dassault Systèmes Engineering Services to simulate the fluid mechanics in the canteen. With the help of the Engineering CFD Simulation (Computational Fluid Dynamics), various scenarios were simulated and visualized for the reopening.

Based on this, an effective Risk management strategy implemented. For this, the canteen was completely mapped as a digital twin with Simulia Powerflow. The air currents including the entire ventilation system were simulated in it. The transport of potentially contaminated droplets that are exhaled is also simulated.

Ergonomic computer workstation in the office and home office

Ergonomic computer workstation in the office and home office

Safe countermeasures can be taken using the CFD simulation. With the initiative Back to work GEA would like to fully reopen its headquarters. Together with Dassault Systèmes, a three-dimensional virtual twin of the canteen was created. “I see the digital twin more as a digital puppet that we let dance during this time,” says Erich Nitzsche.

Risk Management Strategy

With the CFD Simulation wurden Particle movements simulated by coughing or sneezing from infected people. The flow simulation showed how the virus spreads through the air and contamination takes place on surfaces such as plates, trays and tables. Unexpectedly, the virtual twin also showed areas with a particularly high virus load.

With the CFD Simulation wurden Particle movements simulated by coughing or sneezing from infected people. The flow simulation showed how the virus spreads through the air and contamination takes place on surfaces such as plates, trays and tables. Unexpectedly, the virtual twin also showed areas with a particularly high virus load.

The results of the flow simulation help GEA to better understand the behavior of air currents and to recognize possible virus spread. The spread of larger droplets or aerosols in the air after breathing and coughing are checked at various points in the canteen. From this could Recommendations derived to support GEA in the decision-making process to fully open the canteen. Realistic simulations also help to communicate new measures and to further sensitize employees.

The findings from the CFD simulation are now used at GEA for the development and implementation of an effective risk management strategy. She should be for more Security in the canteen to care. This includes adjustments to entrances and exits, seating, and a clear separation of the kitchen area from the food counter. Changes also need to be made to ventilation. In addition, further security measures are intended to protect the kitchen staff.

Collaboration with Dassault Systèmes

"The Flow simulation enables valuable learning processes and will play a major role in our decision-making processes to reopen our canteen, ”says Erich Nitzsche. “The results of our collaboration with Dassault Systèmes exceeded our expectations and showed a new approach for us.

Numerical fluid mechanics for early analysis

Numerical fluid mechanics for early analysis

especially the Conversion from 2D to 3D data was surprisingly easy. Thanks to Computational Fluid Dynamics, we can now ensure the health of our employees in a more targeted manner and at the same time reduce the negative impact on our business. Choosing Dassault Systèmes therefore pays off immediately. "

Inform employees at GEA

GEA is planning the Employees to become familiar with the simulation results. The company uses this to communicate why and how new measures are being taken. In addition, it should be shown which role technology played in decision-making.

“Virtual worlds are revolutionizing our relationship with knowledge and opening up unimaginable possibilities,” explains Klaus Löckel, Managing Director Eurozentral at Dassault Systèmes. “Our Simulia applications reveal the invisible by representing the time and space of a process in the environment. GEA can now understand this, take measures to deal with the coronavirus crisis and thus put the safety of its employees first.”

You might also be interested in...

Artificial Intelligence | trends and developments

3Dexperience World and Conference

Reduce carbon footprint | That's how it's done!

Solidworks 2024 | CAD software by and for users

Dassault Systems | The 3DExperience Company