Construction software for lightning-fast product development

- Details

- Hits: 5195

MSC software (MSC) published with Apex Generative Design 2020 a trend-setting one design software. Development engineers and designers can use it to explore ideas that were never thought possible and quickly perfect designs by optimizing every component of their construction in just one step. This allows innovative products to be converted 80% faster develop.

Content of the technical article

- Design examples created with the design software

- Design software significantly reduces development time

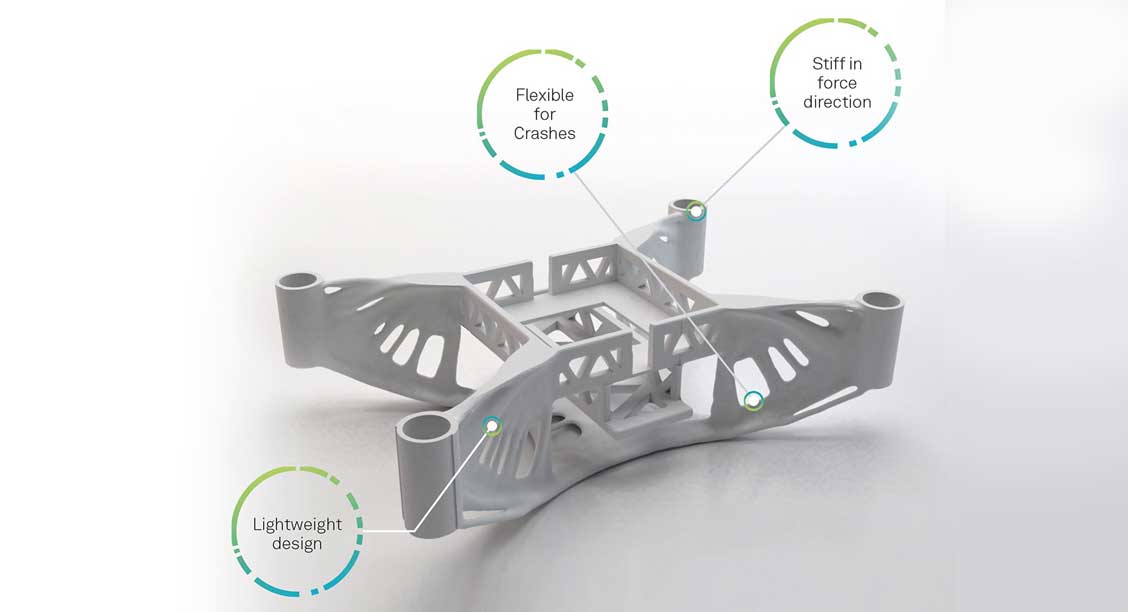

The design software produces smoothed Designs for lightweight componentsbased on the technical development goals. The iterative process of eliminating unsuitable designs is eliminated. Instead, engineers sound out the design space and find even better and new solutions by fine-tuning the tested, production-ready design proposals.

CAD automation creates freedom for the designer

CAD automation creates freedom for the designer

The new design software is suitable for development and construction in all imaginable Industries. Developers can now create perfect designs in the same time as they would have used conventional workflows to create, test and discard an initial prototype.

Design examples created with the design software

Following Product developmentExamples show what the design software can do:

Following Product developmentExamples show what the design software can do:

- A surgeon developed a smarter one Implant with a lattice structure that has already been tested for its manufacturability using 3D printing. It is the same weight as the bone it is replacing. More biocompatibility, better connection with the muscle and patient comfort were found in this Medical Technology Example implemented.

- A pair of Aviationingenieur has redesigned a product step by step for lightweight construction. The operating behavior and safety have been preserved, and efficiency has also been improved.

- A development engineer in the automotive industry is 56% lighter Motorcycle frame developed, thereby increasing the range and reducing fuel consumption.

- A manufacturer was able to take full advantage of the possibilities of additive manufacturing as well as optimize designs in order to also brand new products right the first time.

"Designing an optimal product that takes full advantage of the available technology is a cumbersome process these days that requires developers to compromise," says Thomas Heron, Director Generative Design at MSC Software. "Designers are enthusiastic about our design software because it thinks how they and products improve through smart engineering decisions - and much faster."

3D simulation software designed by power users

3D simulation software designed by power users

Design software significantly reduces development time

“Users report that the Time for your designs reduced by 80% because they were able to reduce the number of different CAE software tools and manual intermediate steps. They have also automated the optimization process and reduced their workflows.

“Users report that the Time for your designs reduced by 80% because they were able to reduce the number of different CAE software tools and manual intermediate steps. They have also automated the optimization process and reduced their workflows.

Now they can produce products that, for the first time, are tailored to technical and commercial requirements in terms of design, behavior and cost,” comments Mr. Reiher.

Despite its high performance, the design software MSC Apex Generative Design runs on a normal laptop. The user receives the first design drafts within an hour. A final design is then available within hours.

Thanks to easier accessibility, an intuitive user interface is created. Users can define design goals even without special CAE knowledge. Based on an existing design, drafts can be created directly with the CAD software or from CAE Create models.

Design problems excluded from the start

The construction software already excludes design problems in advancethat would result in extensive changes at a later point in time during the engineering process. This is particularly advantageous with new manufacturing processes such as additive manufacturing. Here can the 3D Print-Teams use the solution as a Design for Additive Manufacturing (DfAM) tool.

The construction software already excludes design problems in advancethat would result in extensive changes at a later point in time during the engineering process. This is particularly advantageous with new manufacturing processes such as additive manufacturing. Here can the 3D Print-Teams use the solution as a Design for Additive Manufacturing (DfAM) tool.

The tool optimizes the topology and intelligently smooths the construction in one step. This results in components with a low risk of distortion and bionically printable geometries. Resulting components are automatically optimized to the required profile. The material consumption is consistent with the stress distribution and strength requirements.

MSC Apex Generative Design Software integrates with industry leading simulation tools Simufact additives for metals and Digimat AM for plastics combine. This reduces printing errors and makes optimal use of the material.

Solidworks 2022 | CAD software by and for users

Solidworks 2022 | CAD software by and for users

After the development software was first released in November 2019, the new version offers further control options. Developers can more easily adjust how complex the created design becomes and how much the fixation points can be reduced. There are productivity advantages of the underlying MSC Apex platform such as the direct export of models (networks) into CAD Formats. The results of the generative design optimization can thus be used in CAD / CAM production.

Presentation of the new construction software release