yesterday | Product development archive

- Details

- Hits: 1313

Read and experience how the popular CAD software SolidWorks has developed in recent years. Here you will find videos, interviews, applications and many exciting highlights. You can find the current Solidworks News here.

Contents

- Solidworks 2020: CAD connection to 3Dexperience

- Solidworks 2019: Products get into production faster

- Solidworks 2018: CAM integrates design into the manufacturing process

- Agrilution conjures up a garden in the kitchen with Solidworks - statement

- Solidworks 2015: Intuitive with a focus on production

- Solidworks 2011: The user is the source of the ideas

Solidworks 2020: CAD connection to 3DExperience

15.10.2019 | DS has introduced Solidworks 2020, the latest version of its 3D design and engineering portfolio. Optimizations, new functions and workflows in the software enable more than six million users to use their Product development accelerate and can improve - from the concept to the finished product.

Integration of the process chains - Interview with Uwe Burk

In our interview about the new Solidworks release we have Uwe Burk, Vice President, Eurocentral Sales, Professional Solutions, DS in Munich asked the following questions:

-

Solidworks on the SPS 2019: What improvements does the new release offer?

-

Why is the integration of process chains so important?

-

Are there any other basic improvements?

The interview was given on November 26, 2019 at the SPS in Nuremberg.

Interview with Jeroen Buring, Solidworks

Interview with Jeroen Buring, Solidworks

The users can improve the system performance in day-to-day operations, streamline work processes and you Design-to-manufacturing ecosystem from the desktop to the cloud through the seamless connection to the 3dexperience-Expand platform. With Solidworks, the DS research and development team addresses a variety of improvements requested by the community. By seamlessly connecting with the 3D Experience Platform, Solidworks addresses upcoming trends and business needs in global markets. These require new levels of collaboration and agility to deliver new solutions to customers faster and more cost-effectively.

This is new in Solidworks 2020

With the new Detail mode You can open drawings in seconds and continue to add and edit annotations in the drawing. Detail mode is particularly useful when users need to make minor changes to drawings of large assemblies or drawings with many sheets, configurations, or resource-intensive views.

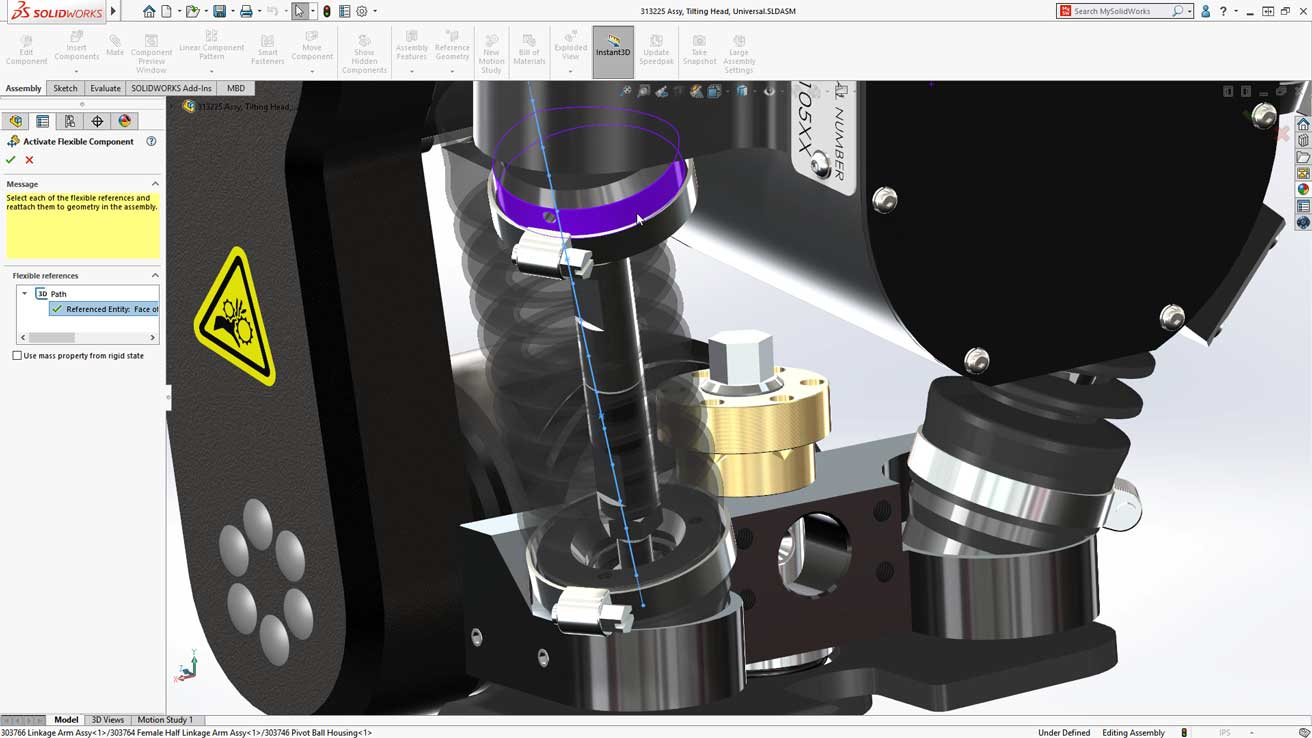

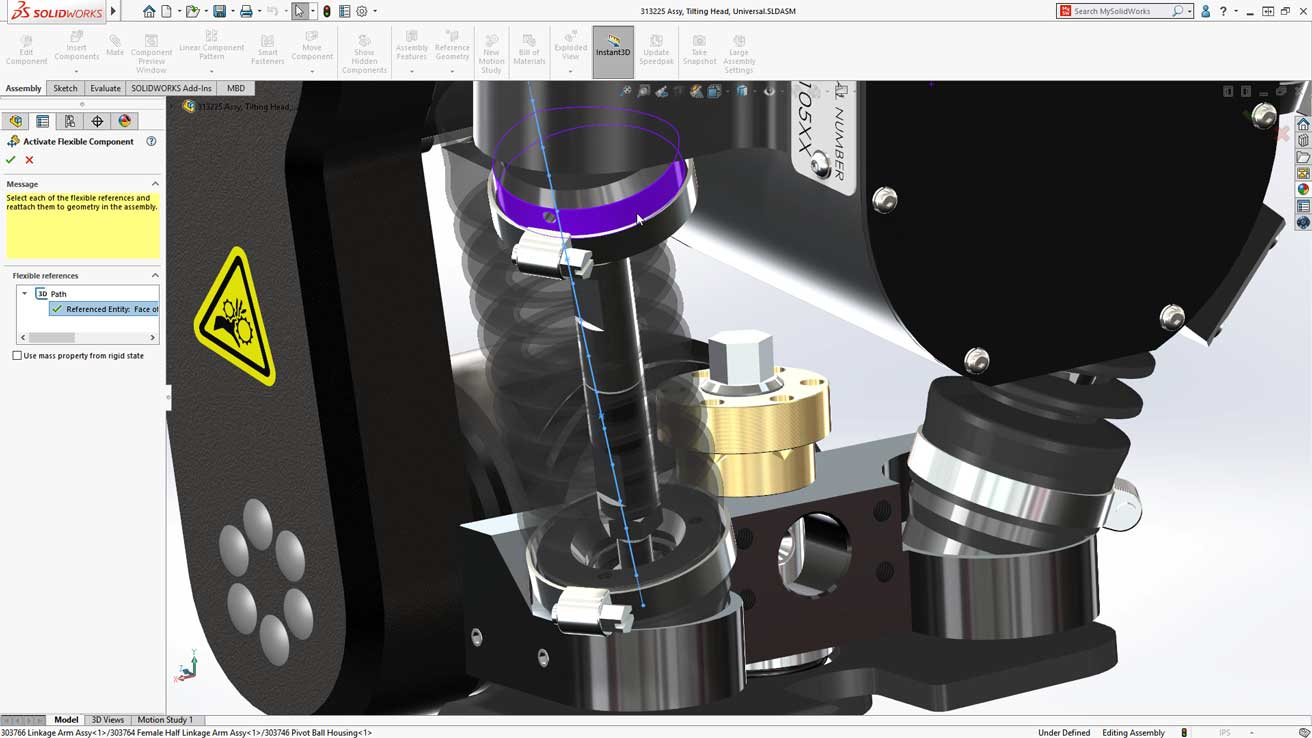

Flexible components is a new feature that allows users to view the same part under different conditions in the same assembly. For example, the same spring could appear twice in the same assembly, but under two different conditions: compressed and uncompressed. Flexible components can be used for many construction applications, such as Springs, bellows, hinges, sealing rings and in general any part that can be bent or changed its state.

Improvements Solidworks PDM (Image), Electrical Connector and a new PCB Connector support comprehensive electronics design and data management, including secure storage, indexing and versioning of all user data. At the same time, closer collaboration between ECAD and MCAD teams is made possible.

Growing number of cloud solutions

With Solidworks 2020 and the solution portfolio of 3D Experience Works, the 3D Experience Platform offers a growing number of interlocking and cloud-based solutions to every aspect from concept development through development and manufacturing to delivery of products too support. This enables users to reduce friction losses in their design-to-manufacturing processes. These include, for example, 3D Sculptor with the Xshape application (modeling of sub-assemblies), 3D Creator with the Xdesign application (parametric modeling), 3D Component Designer (data management), Project Planner and Structural Professional Engineer (extended simulation).

Interview with Klaus Löckel Dassault Systèmes

Interview with Klaus Löckel Dassault Systèmes

Like on the SolidWorks World 2019 Announced earlier this year, all of these cloud-based solutions will be part of the 3D Experience Works portfolio. The aim is to combine the performance and breadth of the 3D platform with the simplicity and user-friendliness of Solidworks.

“We are not only expanding the Solidworks portfolio with powerful new functions, but also connecting it to the cloud, the only holistic digital solution platform in the world, via the 3D Experience platform. We are thus building a bridge to our platform-based portfolio and opening up the advantages of the 3D Experience Works offers to our users, ”said so Gian Paolo Bassi, CEO, Solidworks, DS. "This gives companies the opportunity to use their inventiveness in the course of the industrial renaissance for new ways of innovation, collaboration and production."

Solidworks 2019: Products get into production faster

20.09.2018/2019/XNUMX | Solidworks XNUMX helps innovators get their new designs into production faster. In addition, the design ecosystem supports engineering performance and attention to detail, and solves complex problems. New features offer, among other things, more flexibility when testing large assemblies and VR / AR experiences of designs through Extended Reality.

The latest version of the 3D design and engineering applications from DS not only helps to improve the development process, but also aims to create new experiences for a new type of customer in today Industry renaissance to accomplish.

Web-based gear calculation for designers and developers

Web-based gear calculation for designers and developers

With the 3D Experience Platform from DS, Solidworks 2019 supports the process from development to production with digital functions to Solution of complex construction tasks and to facilitate the detailed work in engineering. New features let development teams better manage large amounts of data and create more complete digital views of a design. New technologies and workflows improve collaboration and allow immersive, interactive experiences during engineering.

Telescope construction with 100.000 parts

"With Solidworks, we are supporting the realization of the 10-meter Maunakea Spectroscope Explorer (MSE) telescope, which will open up new avenues for scientific discovery," says Greg Green, mechanical designer / instrument maker of the Canada-France-Hawaii telescope system. “Our development generates a large and growing data set. The production-ready version of the telescope will ultimately contain over 100.000 parts. So we needed technology that could handle large construction projects, and Soldworks can do it. "

The 2019 version also offers extended functions e.g. B. at the Examination of large constructionsthat gives users greater flexibility to quickly query or change models. It uses a new graphics architecture for parts and assemblies. This architecture provides a more responsive real-time display, especially on large models. It uses modern Open GL (4.5) and hardware-accelerated playback to maintain a high level of detail and frame rate when panning, zooming or rotating large models. In addition, with version 2019, teams can also communicate with participants outside the design community by marking parts and assemblies directly (pen / touch enabled), saving them with the model and exporting them as PDF.

Extended, virtual and commented reality

Another important feature of the Extended Reality (XR). This new application lets you publish CAD data created in Solidworks, including lighting, cameras, materials, stickers and animations for motion studies, and experience it with virtual reality (VR), augmented reality (AR) and web viewers. Ever cheaper immersive devices contribute to the growing technology ecosystem and the increase in interactive experiences. With XR, users can improve collaborative internal and external design reviews, communicate designs more effectively, and train users on how to assemble and handle the products. This increases trust in the designs during the entire development process.

Calculate fit calculator easily online

Calculate fit calculator easily online

“The latest version of Solidworks is packed with improvements and innovations based on knowledge and feedback from the user community. We're always evolving our solutions in terms of usability, quality and productivity, and the 2019 edition delivers a complete design ecosystem, ”says Gian Paolo Bassi, CEO Solidworks at DS. “Designers and engineers who prioritize performance, attention to detail and innovation and are looking for the storytelling functionalities of VR and AR can now experience the prototyping shop of the future, in which digital construction data facilitate the visualization of parts in 3D and improve the transition from virtual to real .

Solidworks 2018: CAM integrates design in the manufacturing process

24.10.2017/3/2018 | Solidworks launches its CAD software for XNUMXD design and engineering version XNUMX. The new release offers integrated, end-to-end solutions for the design and manufacturing process. Businesses of all sizes can thus break new ground in the manufacture of parts and products and quickly bring their ideas tailored to the individual needs of customers to market.

Driven by the 3D Experience platform, Solidworks 2018 supports a production-oriented design strategy. The solutions simplify the interactions between the various disciplines throughout the entire product development process. This uniform process uses Smart Manufacturing - a networked and seamless flow of data that is available to all teams involved in product development anytime and anywhere. It does not matter when, where and in which format the data is required. The data does not have to be transferred from one system to another.

The markets are very competitive these days. customer retention comes from outstanding experiences that go far beyond the purchase and use of a product. This inspires companies to innovate in all areas of their business activities. But outdated organizational structures, processes and tools separate design aspects from those of manufacturing and product development. This can lead to errors that negatively impact collaboration, schedules, and budgets.

The markets are very competitive these days. customer retention comes from outstanding experiences that go far beyond the purchase and use of a product. This inspires companies to innovate in all areas of their business activities. But outdated organizational structures, processes and tools separate design aspects from those of manufacturing and product development. This can lead to errors that negatively impact collaboration, schedules, and budgets. With Solidworks 2018, however, the Teams work together at the same timeto design products or parts faster and more cost-effectively, to validate their functions and manufacturing capability, to manage data and associated processes and to optimize, automate and test production. By integrating ideas into the design process at an early stage, changes can be managed quickly and easily. They flow automatically into all associated models, programs, drawings and documentation.

It plays Solidworks CAM, a new application in the 2018 release, plays a central role: It enables rule-based processing in connection with know-how acquisition in order to be able to further automate production programming. Designers and production engineers gain a deeper insight into their designs, can make more informed decisions and create prototype parts faster. You can even do the manufacturing yourself for better control of quality, costs and delivery. This enables the implementation of new “build-to-order” strategies with user-defined parts that are automatically designed and programmed in seconds instead of hours.

Andreas Spieler presents the new products in a nutshell

Andreas player, Technical Director Solidworks, Dassault Systemes Deutschland GmbH in Munich presents the new features of the 3D design and engineering software Solidworks 2018. The statement was given at the press conference on October 13, 2017 in Munich.

Agrilution conjures up a garden in the kitchen with Solidworks - statement

13.10.2017 | Presents at the Solidworks press conference Maximilian Loessl, Co-Founder & CEO Agrilution GmbH, Munich, presents the first intelligent kitchen appliance for herbs, salads and vegetables for the home with the Plant Cube and explains the role Solidworks played in the development.

Solidworks 2015: Intuitive with a focus on production

22.10.2014/2015/3 | Solidworks XNUMX is the latest version of the XNUMXD design suite of applications. The new release offers cloud-based functionalities and opens up new opportunities to improve productivity, optimize work processes and reduce operating costs. Solidworks 2015 covers all aspects of the product development process with an intuitive, integrated 3D development environment, the tools for 3D construction, 3D simulation, electrical development, product data management and technical Communication provides.

In addition, the new feature offers Collaborative sharing access to the 3DExperience platform and its cloud-based possibilities. This allows designers and technicians to easily work in multiple disciplines, which shortens the design cycle, increases productivity and brings products to market faster. More than 90% of the functionality of SW 2015 is based on direct suggestions from our customers.

In addition, the new feature offers Collaborative sharing access to the 3DExperience platform and its cloud-based possibilities. This allows designers and technicians to easily work in multiple disciplines, which shortens the design cycle, increases productivity and brings products to market faster. More than 90% of the functionality of SW 2015 is based on direct suggestions from our customers.

With the availability of the 3DExperience platform, users can connect their desktop applications to the cloud, develop new business processes and discover the advantages of supported next-generation applications, such as the upcoming SW applications in industrial design. Users will be able to use the new features, such as the Aesthetics of consumer goods and clothing to improve, Construction to simulate and to create infrastructures and machine tools better than ever.

This is new in Solidworks 2015

To improve productivity, SW 2015 is concentrating on construction instead of on the modeling software new functions for faster creation of geometries. Faster information exchange is made possible by improved overall performance, faster analysis and optimized strategies. The information is given to users so that they can make better decisions faster and design more productively. An improved graphical user interface provides a clear view of important data so that the focus is on design. By simulating numerous construction scenarios, the user can quickly evaluate the evaluation of various load combinations on a model and track the results. The new My Solidworks Standard and the Professional Maintenance Contracts offer over 100 hours of training materials and online learning content.

3D simulation software designed by power users

3D simulation software designed by power users

Collaborative sharing is used to improve work processes: With easy access to tools for social collaboration and online data management, users benefit from faster development and decision-making. That Treehouse Serves top-down design through the visual creation of assemblies and the ability to manage product structures at the beginning of design projects. With the mobile connectivity "Web2 for Solidworks Enterprise PDM", users can connect to Enterprise PDM anywhere and anytime.

Lower operating costs

The following functionalities allow the reduction of the operating costs:

- "Model Based Definition" solution to improve communication between the design and manufacturing team

- "Inspection" - simplified documentation creation that allows users to quickly set up and compare the reference data needed to inspect parts of production.

- "Electrical" - Rapid development of circuit diagrams and integration into the 3D model with improved Cablestree and system integration

- "Improved cost analysis" - cost estimation over numerous manufacturing processes

Through automatic processing of 3D models can be Material- or determine manufacturing requirements. This function is particularly useful in the clothing, shoe and upholstery industries as well as in shipbuilding. Thanks to the creation of asymmetrical roundings of components, assemblies and surfaces, users in the high-tech, Medicine and consumer goods with greater flexibility in modeling ergonomic and stylistically appealing designs. The exact development of construction and machine tools with automated roller chains ensures their operation and usability.

Solidworks 2011: The user is the source of the ideas

17.10.2010/2011/XNUMX | With the announcement of Solidworks XNUMX, DS Solidworks breaks new ground for a still faster product design, intensifies cooperation and increases the designer's awareness of manufacturing issues. The new line of products includes hundreds of improvements inspired by users who use Solidworks to design new products every day, validate their performance, communicate with partners, manage design data and care about the environmental impact of their products.

17.10.2010/2011/XNUMX | With the announcement of Solidworks XNUMX, DS Solidworks breaks new ground for a still faster product design, intensifies cooperation and increases the designer's awareness of manufacturing issues. The new line of products includes hundreds of improvements inspired by users who use Solidworks to design new products every day, validate their performance, communicate with partners, manage design data and care about the environmental impact of their products.

When developing new releases, the CAD specialist not only realizes its own ideas, but also very much responds to the wishes of its users. "This year we paid even more attention to the wishes of our users," says Andreas player, Product Manager at Solidworks. About 80% of the news this time comes at the suggestion of users who work with it every day and are probably the best idea generators. "Otherwise the 'sexy features' were always in the foreground of the development, which our users do not have to do without in this version either."

Faster and smarter work

The faster a new product comes onto the market, the greater the success will be for everyone involved; the time pressure does not decrease, but increases. Solidworks continues this tradition with the 2011 version with the following highlights away:

- Drawing detailing functions in the CAD software relieve the designer of the time-consuming and labor-intensive manual dimensioning. With just one click of the mouse, dimensions can be aligned, offset or centered without any overlap. With just a few clicks of the mouse, drawings are clearer than ever and give a more professional impression.

- The 2D simplification accelerates the analysis of parts. The user simply selects an intersecting plane, applies loads and bearings, and then performs a static, nonlinear, or thermal analysis or pressure vessel study. SW simulation calculates the results immediately and displays them on the entire 3D model without delay.

Alfred Pracht relies on Solidworks for luminaire development

Alfred Pracht relies on Solidworks for luminaire development

- With the module for Cooling electronic components thermal analysis is quick and easy to set up and run. This ensures that the electrical and electronic components of a product are not damaged by heat. The new module for heating and ventilation works in a similar way. The parts libraries have been expanded to include fans, materials, dual resistor components, and integrated circuit packages. Local air quality, ambient temperature and Joule heat are now available variables for analysis.

- The menu bar in Solidworks Enterprise PDM, the software for managing product data, speeds up access to important designs. The menu bar, which appears on the right in Windows Explorer, combines the simplicity of Windows with the advantages of an enterprise-class data management strategy, creating the basis for better collaboration, more control and the reuse of valuable design data.

Thanks one more efficient memory management For large designs and lengthy work sessions, all Solidworks 2011 products are faster and more reliable.

Intensified communication and collaboration

The faster those involved in the project grasp the design intent and the direction of development, the easier the path to the finished product will be. For this reason, the CAD provider is constantly striving to use the powerful functions of Solidworks for the Collaboration and visualization to improve further.

- New in version 2011, for example, is the ability to use Photoview 360 to view interesting, photorealistic renderings easy to create. The software is now fully integrated with the CAD software so that the user has a unified environment for development and rendering.

- With the new Walkthrough functions the user can now put his customer in the position of the development and give him a detailed impression during the “tour”. The user can easily navigate through his design visions with the mouse or a screen console - paths do not have to be defined in advance.

Product development at Fronius with PLM software from PTC

Product development at Fronius with PLM software from PTC

- Solidworks customers can also work more closely with their partners by sending them detailed, but not over-detailed designs. The new Defeature tool makes it easy to remove unnecessary details or sensitive data (intellectual property) before exchanging documents.

- For better communication beyond the design team, the 3DVIA Composer, the communication software for the technical area, equipped with a new dynamic and interactive "flow chart" function with which customers can use interactive images to give process instructions. Using the actual product, the user can create a step-by-step linked, narrative description for the recipient, for example a colleague in production, a major customer and prospective buyer or an end user. By dragging and dropping views, interactive flows are created that are clear, distinct, and effective. Magnetic lines are another innovative feature that increases productivity. With just a few clicks of the mouse, content can be clearly and neatly organized.

Awareness of manufacturing issues

An active communication between development and production contributes to the fact that the product ideas can actually be manufactured and costly delays, rejects and rework are avoided. The following features, for example, ensure this:

- Solidworks 2011 is equipped with powerful functions that automate the placement and documentation of welds. With the tool Intelligent welding the user can select and display the course of weld seams. With the extended features for fillet and joint welds, he specifies the type of weld seam and prepares weld seam connections. Solidworks automatically compiles the data on the number, length and type of the weld seam in new welding tables, which can be broken down in detail for cost analysis and the preparation of offers. New, visible weld clearances can be applied to pipe joint-to-pipe joint, pipe-to-pipe and pipe joint-to-pipe joints to ensure successful creation of the welds.

4K 3D printing for space and Industry 4.0

4K 3D printing for space and Industry 4.0

- With the Bending calculation tables the user can quickly calculate the developed length of the sheet metal parts and thus detect errors at an early stage.

- With the integration of Solidworks Design Checker with Solidworks Enterprise PDM, the Approval of constructions optimized for production.

- Thanks to the expanded selection of manufacturing and usage areas in Solidworks Sustainability (now with Australia and South America) it is easy to weigh the impact of manufacturing decisions on a product's carbon footprint. Custom materials are now also supported.

- The creation of pipes, hoses and guide lines, especially when using To store and hangers, comes with the Line routing functions still simplified. The user can now follow existing geometry, for example a steel beam or wall segment, to guide the conductor path. DW links the outside diameter (not the center line) of the pipe, hose, cable, or pipe to the geometry.

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.