Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

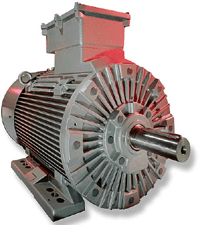

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

The shaft-mounted geared motors of the "Compacta" series from Framo Morat offer a high power density and can be used reliably and flexibly. With the Compacta AG 160 model, the Black Forest drive specialists have once again significantly increased the output per volume unit: it delivers up to 1600 Nm torque, which is only 37,5 x 20 x 11 cm3 large and 13 kg light drive.

The shaft-mounted geared motors of the "Compacta" series from Framo Morat offer a high power density and can be used reliably and flexibly. With the Compacta AG 160 model, the Black Forest drive specialists have once again significantly increased the output per volume unit: it delivers up to 1600 Nm torque, which is only 37,5 x 20 x 11 cm3 large and 13 kg light drive.

Aerotech presents a new one with the HEX150 RC Hexapod in front. With a diameter of 150 mm, this smaller brother complements the existing product family with a diameter of 500 and 300 mm. In addition to working for Quality Assurance in the Measuring and testing technology it is particularly suitable for automotive, electronics, mechanical engineering and medical technology.

The four-pole motor 2264… BP4 from Faulhaber achieves a torque of 59 mNm with a weight of only 140 g and a diameter of 22 mm. The engine also manages up to 34.500 rpm-1, The reason for this performance is the coil's new coil segment winding, developed for the BP4 family of brushless DC motors.

The four-pole motor 2264… BP4 from Faulhaber achieves a torque of 59 mNm with a weight of only 140 g and a diameter of 22 mm. The engine also manages up to 34.500 rpm-1, The reason for this performance is the coil's new coil segment winding, developed for the BP4 family of brushless DC motors.

The worm wheel geared motors of the "DCGM 43 T42" series from Gerdt Seefrid have been standard in many adjusting devices for years. They are traditionally used in short-term operation. Now a new area of application through the use of brushless DC motoren which allows the drives to also be used in continuous operation.

A-Drive's NEMA 17 ZEN Hollow Shaft Actuator features a novel magnetic design that stepper motor gives previously unattainable properties. The features include very high accuracy, an extremely compact design and silent operation. The stepper motor can be flexibly adapted to almost any application and opens up numerous new areas of application that were previously reserved for larger series.

A-Drive's NEMA 17 ZEN Hollow Shaft Actuator features a novel magnetic design that stepper motor gives previously unattainable properties. The features include very high accuracy, an extremely compact design and silent operation. The stepper motor can be flexibly adapted to almost any application and opens up numerous new areas of application that were previously reserved for larger series.

The new single-stage spur gear motors from ABM Greiffenberger are energy-efficient, low-maintenance and particularly durable. In addition, the drive technology specialist has added a medium version with basic equipment and standard features to its "Premium Line" motor series, which is suitable for use in pumps and compressorsen suit.

The new single-stage spur gear motors from ABM Greiffenberger are energy-efficient, low-maintenance and particularly durable. In addition, the drive technology specialist has added a medium version with basic equipment and standard features to its "Premium Line" motor series, which is suitable for use in pumps and compressorsen suit.

Starting larger electric motors gently avoids large inrush currents and thus protects the supply network. It also minimizes the mechanical stress on all components. For pumps, compressors or compressorsThere are also special hydraulic or pneumatic factors of the driven fluid conveyor. In order to be able to easily take all parameters into account, Aucom has provided the EMX4 soft starter with a slot for a pre-programmed, intelligent smart card.

Starting larger electric motors gently avoids large inrush currents and thus protects the supply network. It also minimizes the mechanical stress on all components. For pumps, compressors or compressorsThere are also special hydraulic or pneumatic factors of the driven fluid conveyor. In order to be able to easily take all parameters into account, Aucom has provided the EMX4 soft starter with a slot for a pre-programmed, intelligent smart card.

ATB Austria offers a complete series of Ex “d (e)” motors according to the new IE3 efficiency class within the framework of the new IEC / EN 60034-30 standard - from 0.75 to 200 kW. Although "Ex" motors do not come under the new regulation No. 640/2009 of EU Directive 2005/32 / CE, the (petro) chemical and pharmaceutical industries have always been pioneers in the implementation of new (environmentally friendly) applications. Thus, these engines find a wide range of applications in numerous companies that focus on reducing their carbon footprints.

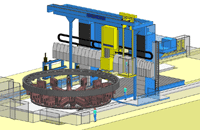

Waldrich Coburg expands its range of technologies to include gear milling. 3 orders are currently being processed in which ring gears or ring gears are completely machined using the technologies of turning, drilling, milling and gear milling. These sprockets come as ring gears, for example planetary gearn for wind turbines, as a ring gear for ore mills or turntables. For the machining of external and internal gears, the machine tool specialist has developed special attachment milling heads with which gears can be machined using the single-part process or the generating process.

Waldrich Coburg expands its range of technologies to include gear milling. 3 orders are currently being processed in which ring gears or ring gears are completely machined using the technologies of turning, drilling, milling and gear milling. These sprockets come as ring gears, for example planetary gearn for wind turbines, as a ring gear for ore mills or turntables. For the machining of external and internal gears, the machine tool specialist has developed special attachment milling heads with which gears can be machined using the single-part process or the generating process.

statement of

on the question: What highlights do you present at the Motek?

With an optimization of Torque motor SRV series from Idam Schaeffler eliminates disturbance forces and disturbance torques of the drives, which with the usual design in Rotary axes and Rotary tables Cause tilting of the axis or the clamping surface in the micrometer range. This tilting of the motors affects the surface quality during precision machining and leads to additional costs due to the necessary rework.

The wide range of high-speed electric drives for almost every requirement from GMN consists of three product groups, which differ in their degree of customization, among other things: MSP basic complete motors, partially flexible solutions from the PSM series and customer-specific special designs.

The wide range of high-speed electric drives for almost every requirement from GMN consists of three product groups, which differ in their degree of customization, among other things: MSP basic complete motors, partially flexible solutions from the PSM series and customer-specific special designs.