Trade fair for metalworking

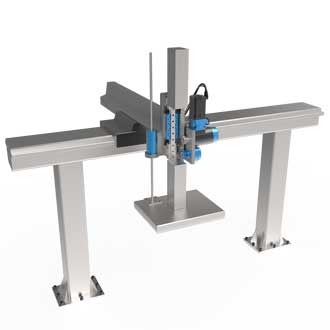

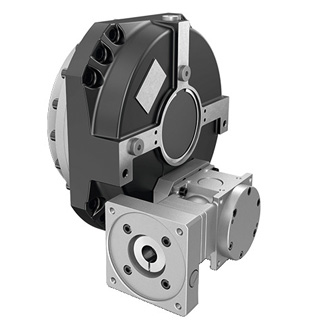

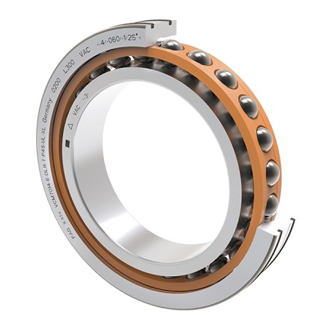

Machining center, sheet metal processing and sheet metal bending machine, lathe, milling machine, tools, additive manufacturing

Image: Deutsche Messe

Trade fair for metalworking

Machining center, sheet metal processing and sheet metal bending machine, lathe, milling machine, tools, additive manufacturing

Image: Deutsche Messe

The EMO is one of the world's leading trade fairs for the Metalworkingindustry. With thousands of exhibitors from all over the world, the fair offers a platform for companies in the industry to present their latest products, technologies and solutions for metalworking technology.

Our Fair Special on the EMO trade fairs, which take place every two years, shows you the highlights of the trade fairs taking place in Hanover and Milan under the patronage of the VDW. Exhibition areas of the world's leading trade fair for manufacturing technology and production are processing centres, sheet metal processing and sheet metal bending machines, machine tools such as lathes, milling machines, tools, additive manufacturing etc.

The EMO Hanover is the World's leading trade fair for production technology and from 2023 would also like to offer a comprehensive overview for well-founded purchasing decisions. As an international business platform, it promotes cross-industry exchange and effective networking all year round.

Under the motto Innovative Manufacturing EMO Hannover presents the latest trends in technological, strategic and organizational developments. With the Future Insights, experts from the manufacturing industry report on current megatrends and key issues relating to business, connectivity and sustainability in production.

In our trade fair special for EMO Hannover, exhibitors and trade visitors and those who don't have time to come to Hannover will find product innovations from the exhibitors for production technology before and after the event. Use our service before, we will keep you up-to-date. The date for the next EMO is the 18. to 23. September 2023 in Hannover.