Trade fair for metalworking

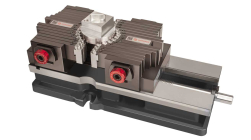

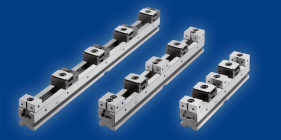

Machine tools, robots, clamping technology, handling technology, software + engineering, precision tools and quality assurance

Image: State Fair Stuttgart

Trade fair for metalworking

Machine tools, robots, clamping technology, handling technology, software + engineering, precision tools and quality assurance

Image: State Fair Stuttgart

Our Fair Special to the biennial event in even years AMB, International Exhibition for Metalworking, shows you the highlights of the event taking place in Stuttgart. Exhibition areas are exciting Machine Tools, Robot, workpiece and tool handling technology, Workholding, abrasive machine tools, industrial software + engineering, Precision tools, components, assemblies and accessories, Measurement Technology and quality assurance and services.

Contents

Monitoring tools digitally in real time, equipping clamping devices with intelligent measuring technology, digital twins and other topics of digitization will determine the picture at the AMB, International Exhibition for Metalworking. Technologies, machines and precision tools are becoming increasingly automated, not least to alleviate the shortage of skilled workers. The AMB fair takes place from 13. to 17. September 2022 held in Stuttgart.

Exhibitors, trade visitors and those who don't have time to come to the exhibition center can find information before and after the event in our exhibition special new products the exhibitor in the form of product reports, user reports or specialist articles.