wireless network | Configure, set up, commission

- Details

- Hits: 21642

The Leantec division of steute Technologies has the Wireless Network Solution nexy for Automation developed by manufacturing and assembly processes. Mobile machines and systems in production communicate directly with the company's IT network via Nexy. Here you will find out how you can make your production more efficient with this wireless network.

Contents

- Wireless network for digitization in industry

- Components for the energy-efficient radio network

- How do I configure and parameterize the Sensor Bridge?

Wireless network for digitization in industry

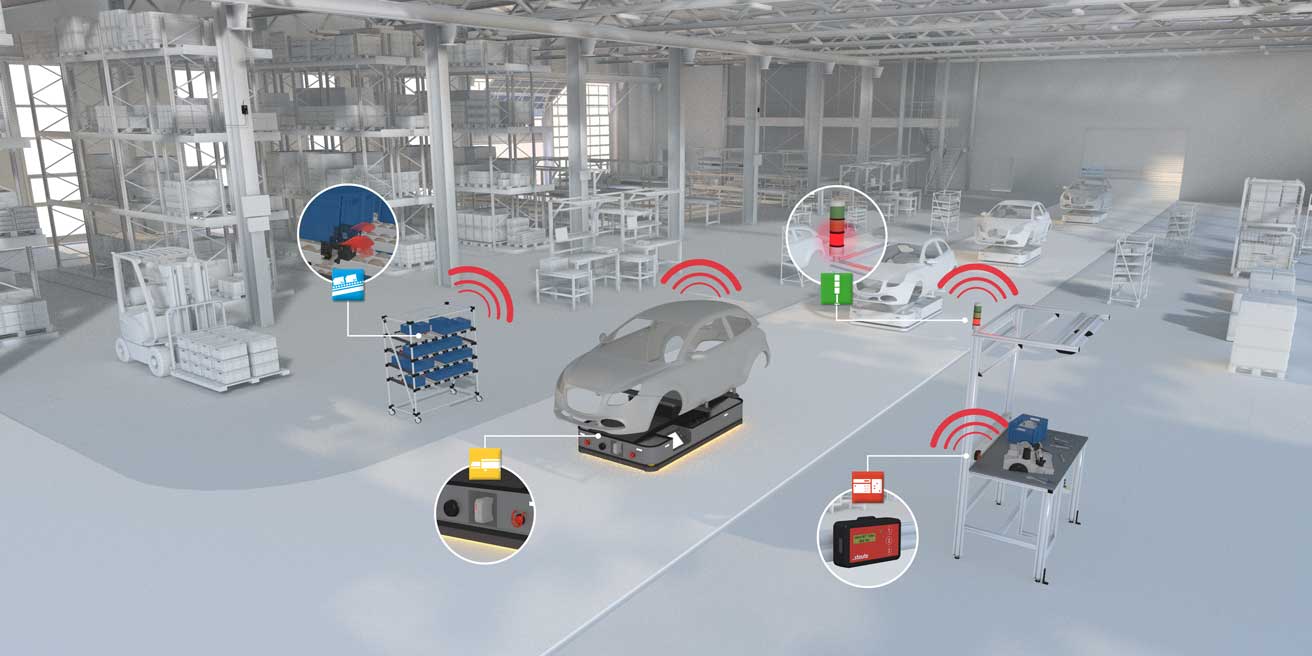

During the digitized factory it depends on the seamless flow of data and information, which extends from the higher-level planning level to the individual machines, conveyor systems and transport containers. When means of transport such as AGVs, tugger trains, mobile systems or movable e-Kanban shelves are used, the signals must be transmitted by radio.

The wireless network solution Nexy transmits the data from switching devices and Sensors in the field in the Internet of Things (IoT) or other higher-level IT systems. These send and receive data via the radio standard Swave.net, which was specially developed for this purpose. The Nexy wireless network consists of sensors/actuators, access points and a Gateway (Sensor Bridge) as a connection to the higher-level IT systems of the user.

Access Points collect the data from the wireless sensors and wireless actuators and transfer them to the sensor bridge, which acts as a service manager for data transfer to the user's higher-level IT systems. This creates a consistent Communication from the shop floor to the management level of the company's IT. A modern dashboard provides clear status visualization of all end devices integrated into the network.

6G network | Bidirectional radio link and Thz receiver

6G network | Bidirectional radio link and Thz receiver

Characteristic for the Nexy software is the simple adaptation to the individual requirements as well as the Openness the network solution. This significantly expands the application and expansion options for the wireless network.

The connected Swave.net field devices receive new firmware updates via radio. These are provided on the Sensor Bridge and automatically distributed over the wireless network. This means that all end devices are always up to date with the latest software without much effort. In addition, the user can automatically save the current configuration of the Sensor Bridge and thus the entire parameterization of the wireless network on an FTP drive. The Sensor Bridge can also communicate with the user’s SAP system via an additional SAP connector.

Optimize material flow in assembly technology

Oct 04.10.2023, XNUMX | How to optimize the material flow on the last meters of assembly processes? Because C-parts are missing, interruptions often occur in practice, even with consistent IT-supported inventory management. Or the presence of these parts increases and ties up space and capital.

Oct 04.10.2023, XNUMX | How to optimize the material flow on the last meters of assembly processes? Because C-parts are missing, interruptions often occur in practice, even with consistent IT-supported inventory management. Or the presence of these parts increases and ties up space and capital.

With Nexy, Steute has a radio-supported one automatic material retrieval system (AMS) was developed to ensure a seamless flow of data and information in intralogistics and production. This makes much more precise production and assembly planning with better supplies possible.

Demonstrator at Motek 2023

On Motek 2023 Steute will use a demonstrator to present the latest version of the Nexy radio network for assembly workstations. For example, sensors on the Shop floor level Containers in material stations, staging areas and workplaces. They transmit their signals to the Sensor Bridge via access points and the Swave.NET radio protocol. This ensures connectivity to the higher-level IT infrastructure (ERP, LVS MES…).

For every installation of the AMS you can add one Dashboard can be configured, which displays the “health status” of the entire system. The access points and sensors are displayed with their current function and battery status. New sensors can be integrated and configured via the Sensor Bridge web interface and on-site in the field via an app.

Logical functions like Traffic light controls (red/yellow/green) are stored and can of course be visualized via the dashboard. There are also various preconfigured applications, including: for the steering of eKanban systems and AGV fleets as well as for Andon systems for order picking and for location-independent control of signal towers via radio. Multiple applications can be operated via one and the same wireless network.

Detect containers in mobile kanban shelves

Wireless sensors developed for assembly technology detect the presence of containers in mobile Kanban shelves. If the specified minimum stock is reached, the system automatically triggers a replenishment order. The fill levels can be visualized on all web-based devices.

Wireless sensors developed for assembly technology detect the presence of containers in mobile Kanban shelves. If the specified minimum stock is reached, the system automatically triggers a replenishment order. The fill levels can be visualized on all web-based devices.

This means that the current stock is on Assembly area always transparent and material availability is guaranteed throughout. This means production stoppages can be avoided and on-site inventory remains lean.

This saves costs, reduces capital commitment and always supplies all assembly stations with sufficient material. This Nexy solution is used, among other things, in the production of electrical appliances, in automobile production or in the manufacture of devices for Medical Technology.

Switch off and wake up AGV fleets in automotive production

A second example of how a radio network increases efficiency in assembly are AGV fleets in the Automobile production. Nexy causes driverless transport vehicles to be switched off and woken up here. In addition to saving energy, the vehicles can simply remain on site during breaks in operation until they are put back into service and do not necessarily have to go to a charging station. Several automobile manufacturers are already using this system in their assembly lines.

Robust Ethernet media converters with low latency

Robust Ethernet media converters with low latency

In both applications, the wireless network serves as a Backbone for the integration of mobile systems into the data world of assembly, production and material supply. The radio system becomes even more efficient because it can be configured very easily and new hardware such as sensors/actuators, access points, Gateways as well as software components such as B. interfaces can be expanded.

Wireless network reduces energy requirements in intralogistics

26.02.2020/XNUMX/XNUMX | The radio network was developed especially for driverless transport systems. For this purpose, it offers a function that is unique to date, which calculates the energy requirements of the Driverless transport vehicles (FTF) lowers. The radio network makes the entire AGV fleet more flexible.

26.02.2020/XNUMX/XNUMX | The radio network was developed especially for driverless transport systems. For this purpose, it offers a function that is unique to date, which calculates the energy requirements of the Driverless transport vehicles (FTF) lowers. The radio network makes the entire AGV fleet more flexible.

The radio network is based on the LPWAN technology developed by Steute Wireless Swave.net. Currently unused AGVs can be put into deep sleep mode, where they only consume minimal energy. If the AGVs are to be used again, they receive a wake-up signal via the Nexy wireless network. With a short response time, it is reconnected and can be used again by the AGV management system. The network's low-power technology is used to control sleep mode.

In practice, the AGV in sleep mode cannot be connected to a charging station. In addition, in many cases the user can choose a lighter, smaller Battery choose without having to reduce the effective duration of use. At the same time, it is guaranteed that the vehicles can be put back into operation with the radio network at any time within a few seconds.

OPC UA The interface and SAP connector for cross-platform data exchange are particularly useful when the Nexy wireless networks have to perform other tasks in addition to the AGV wake-up function, such as material supply via mobile, AGV-supported e-Kanban systems.

Components for the energy-efficient radio network

A radio network for the automated processes in production requires components that are perfectly matched to one another. Steute relies on this standardized radio technologiessuitable for different applications. High-quality wireless sensors are used that are certified according to international standards. Through the use of plug-and-play modules and customer-specific products, the sensor data can be seamlessly integrated into existing IT systems.

Radio receiver with wake-up function

12.01.2021/868/4 | The radio receiver RF Rx SW48-NET-XNUMXS-A XNUMXV for the Nexy radio network was developed for use in driverless transport systems. The unique radio network ensures an energy-efficient Battery Management.

12.01.2021/868/4 | The radio receiver RF Rx SW48-NET-XNUMXS-A XNUMXV for the Nexy radio network was developed for use in driverless transport systems. The unique radio network ensures an energy-efficient Battery Management.

During breaks and shutdowns, the entire AGV system or individual vehicles can be wirelessly integrated into one for up to three weeks Sleep mode in which they do not consume any energy. The vehicles do not need to go to a central charging station for their time-out, but stay in any parking position. The radio receiver, which receives the wake-up signal and forwards it to the AGV control, is supplied with power by a backup battery during this time.

So far this has been a Radio actuator used from the standard program. The AGV manufacturer had to install an additional converter for the typical AGV 48 V power supply on board. The new generation of the RF Rx no longer requires a voltage converter and thus consumes even less energy. In addition, no one takes over now Relais more the switching process. The coupling to the AGV control takes place via optocoupler outputs. This also improves the energy-saving operation of the radio receiver that travels on the AGV.

Ethernet switches | The data driver in the network

Ethernet switches | The data driver in the network

Well-known manufacturers of driverless transport systems already use the wireless wake-up function in their vehicle fleets and system integrations. Some automakers have already included the Nexy in their AGV factory specifications.

Wireless rope pull switch for a secure hold

June 10.06.2020, XNUMX | The following principle has proven successful in partially automated production and assembly lines: If the operator wants or needs to trigger a conveyor stop at one of the linked workstations, he activates a pull switch to bring the system to a safe stop. Such switches are also used to acknowledge or release assembly steps. These often involve solutions Cable switch without safety function to which the pull rope is fixed.

June 10.06.2020, XNUMX | The following principle has proven successful in partially automated production and assembly lines: If the operator wants or needs to trigger a conveyor stop at one of the linked workstations, he activates a pull switch to bring the system to a safe stop. Such switches are also used to acknowledge or release assembly steps. These often involve solutions Cable switch without safety function to which the pull rope is fixed.

In this application, the radio rope pull switches of the RF 96 WH / 90 ° series from Steute have proven themselves especially in automotive production. They send their signal by radio to an assigned receiving unit. Of the wireless operation allows easy and flexible installation of the pull switch without Lines to have to embarrass.

Now the signals can also be transmitted over a radio network. A new variant of the Pull switchequipped with Swave.net radio technology.

Several hundred In this way, wireless switches and wireless sensors can be combined in a network and, for example, integrated into production planning and other systems such as PPS, ERP, MES, LVS, etc. Each individual wireless switchgear can be conveniently configured via the wireless interface.

As an alternative to the RF 96 WH / 90 ° Swave.net, the manufacturer offers the network-compatible Andon terminal with three buttons and two-line display. All Swave.net-capable wireless buttons, wireless sensors and wireless operating devices are also suitable as solutions in mixed operation.

Radio position sensor detects container position

01.10.2019 | transparency and advance planning material flow cannot be achieved with purely wired communication, as the end and intermediate products are in motion. The Nexy wireless network transmits the sensor data to the Internet of Things (IoT) or other higher-level IT systems.

At Motek 2019, the trade visitors were able to use an automatic material retrieval system for KLT container see a use case in production. The network solution automatically detects where containers are located. As soon as the set minimum inventory is reached, it automatically triggers a replenishment order. The fill level views can be visualized on all web-based devices.

EKS Angels | The fiber optic specialists

EKS Angels | The fiber optic specialists

Steute has one especially for such applications Wireless position sensor developed that detects the container position. If staff removes a container or box from the shelf, this wireless sensor solution sends a signal to, for example, B. the ERP system or the warehouse management system. The position sensor can be placed anywhere on the shelf. The position depends on how high the minimum inventory should be. There is always full and up-to-date transparency about the inventory. The Nexy software can be easily adapted to individual requirements.

How do I configure and parameterize the Sensor Bridge?

Jens Lindemmeier answered in five Video Tutorials Questions about the configuration and parameterization of the Sensor Bridge. In it he explains step by step how to set up Nexy using the following topics:

Commissioning of the Sensor Bridge

Commissioning, activation and configuration of the access points

Setting and configuration of groups in the Sensor Bridge

Setting up and configuring actuators and sensors in the wireless network

Configuration of various interfaces

You might also be interested in...

Three stage Enabling footswitch with safety-oriented radio technology

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.