Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

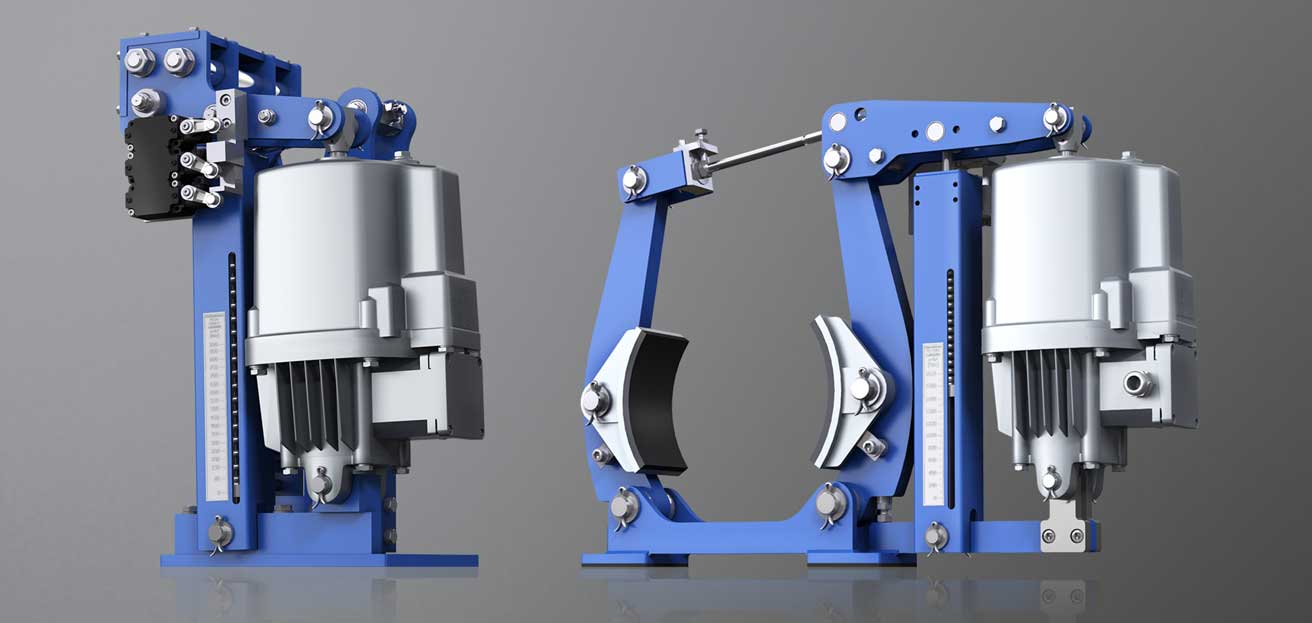

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

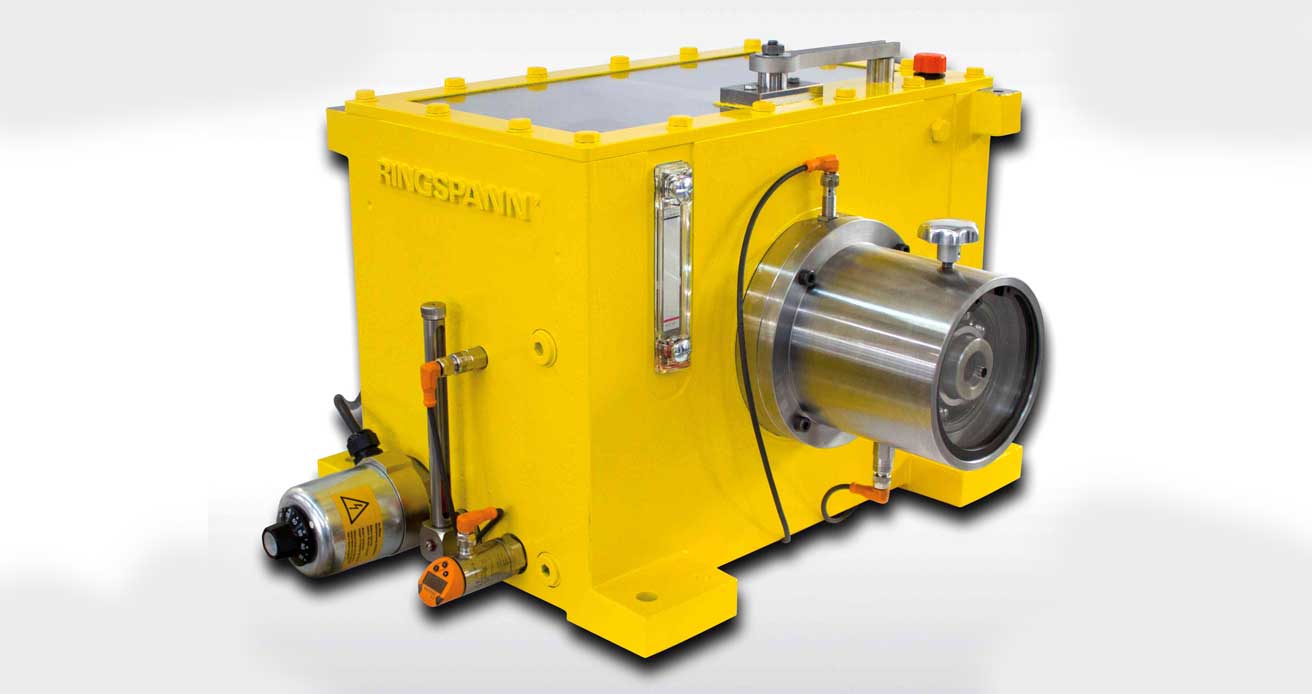

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

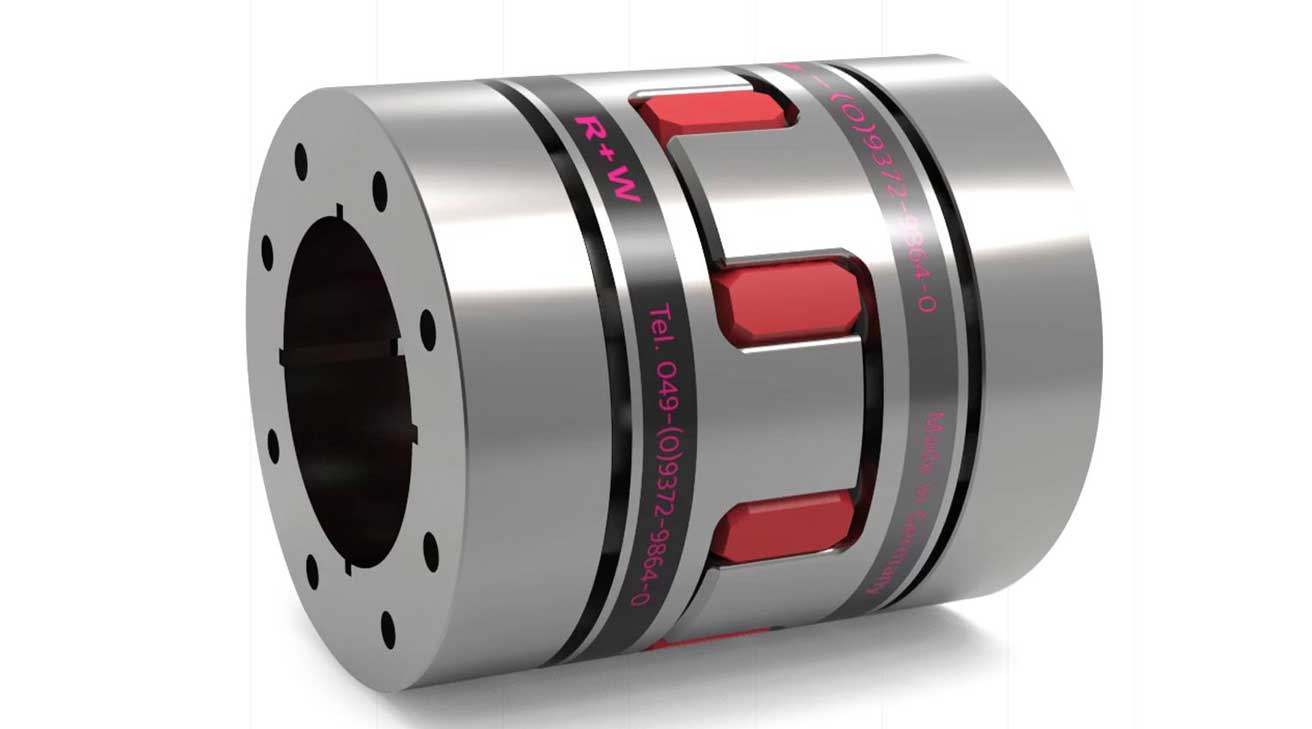

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

Within the disc brake you first think of the bicycle. However, this type of brake is also used in industrial drive systems. These robust brakes can be precisely controlled and are very reliable. Whether as Thruster brake in lifting devices, electromagnetic for the machine tool, as a fixed caliper brake for holding or as a floating caliper brake in the function of a service brake: There are many applications for the type of brake invented by Frederick W. Lanchester.

Collisions in the drive train cause sudden high torque peaks that can damage or even destroy adjacent components. To limit the torque to a defined value, either the Slip clutch or snapping Overload Clutch to disposal. In the portfolio of Orbit Drive Technology the technical user will find a wide variety of safety clutches for a wide range of applications and wide torque ranges.

clamping ring, Collars and clamping couplings secure axes and shafts in jig construction and mechanical engineering. the shaft Collars are very versatile. Here you will find new developments of small drive elements such as Quick release clamping rings for packaging technology Clamping ring with mounting hole from Russia, the versatile wave rings from Misumi or Clamping rings for hollow shaft encoders from Orbit drive technology.

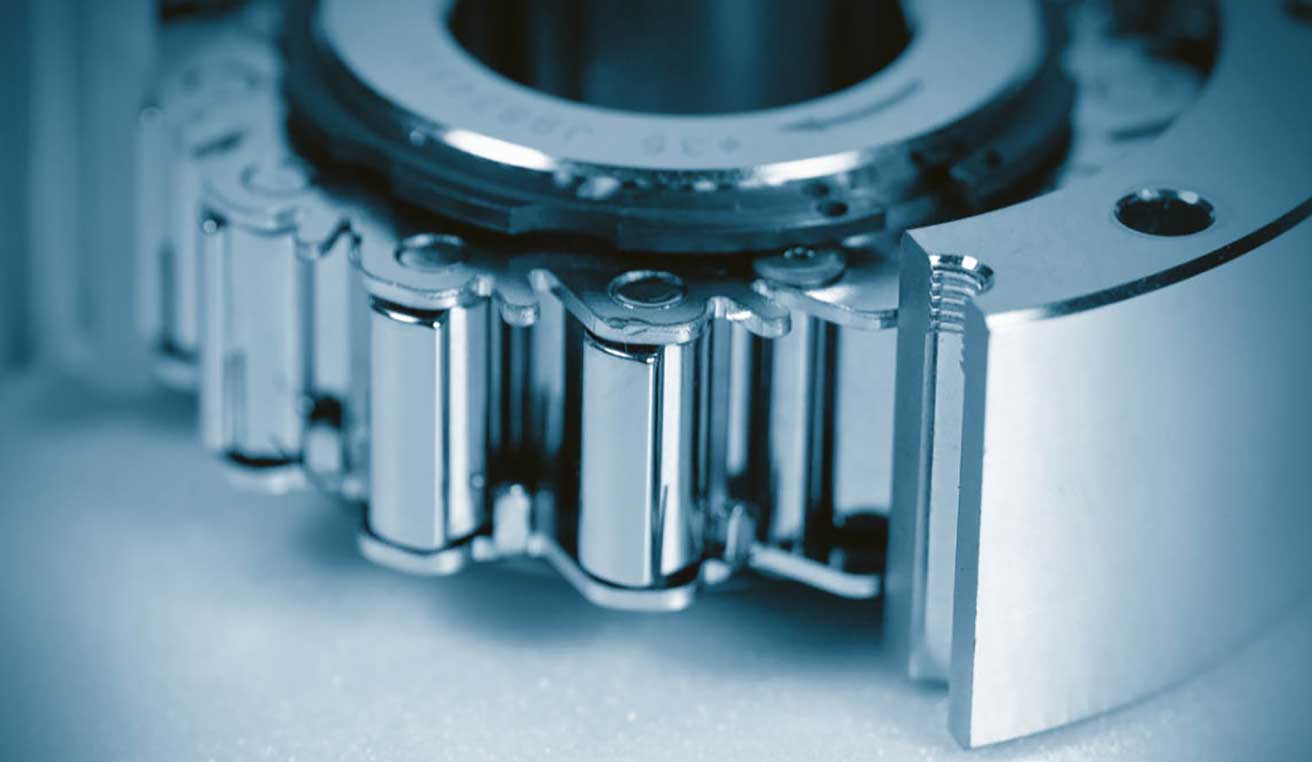

Discover the new products and applications Freewheel clutch, a key element in modern drive systems. This specialized type of coupling, also called Backstop known, allows free rotation in one direction while locking in the opposite direction to prevent unwanted backlash. Find out more about their versatile uses and technical advantages.

Discover the latest developments in the field of Dog clutch – decisive for high-performance drive systems. Our expert insight highlights how these couplings can increase efficiency and reliability. What is very important with elastomer couplings is the plastic or that elastomer, which need to be constantly improved so that they become more efficient.

Discover the advanced Shaft connections from Tsubaki, a market leader in the field of drive elements. Tsubaki offers innovative coupling solutions that combine reliability and precision in drive technology. Find out about their high-quality products that have been specially developed for the demanding conditions of industrial applications.

koco Motion and Adlos have their ingenious, unique servo motor platform can Motion revised. About better reference runs Users can now also look forward to series products. In addition, the cooperation partners now have the connection of DC motors implemented. Previously were at the Servomotor of 2nd generation made electronic and mechanical improvements and further developed the software.

Maximize the safety of your drive systems with one Slip clutch or Frictionto prevent overload damage. This safety clutches protect your valuable machines from excessive torque. Improved materials and precise adjustment mechanisms guarantee quick response and reliable separation when torque is exceeded. Discover the new products and find out more about their function and application.

The ones presented safety clutches of the ST series R + W are available in four different sizes for torques from 1000 to 160.000 Nm. This makes them particularly suitable for reducing the high downtime costs in heavy machinery construction. Shaft diameters from 40 to 290 mm can be adapted. The couplings are absolutely free of play and maintenance and, compared to other safety couplings, have up to 23% smaller outside diameter.

An rigid coupling or Shell coupling offers advantages such as backlash-free shaft connection or high torque transmission. Find out how rigid couplings ensure precise power transmission and fail-safe connections in your drive solution. Optimize your systems with proven solutions known for their robustness and easy installation.

The articulated coupling connects two shaft ends for torque transmission. The torsionally rigid couplings also compensate for large radial and angular misalignments of the shafts. This makes it suitable for applications where precise shaft alignment is not possible or would be costly. With these characteristics she beats them Bellows or Dog clutch. Below you will find innovations from various manufacturers.

In certain applications are Lead Screws an extremely economical alternative for the more precise Ball Screws. Dr. Tretter has now included them in its broad product portfolio and covers a very wide range of diameters and pitches with the trapezoidal thread spindles.