BLDC motor: when the DC motor reaches its limits

- Details

- Hits: 14724

Comes a mechanically commutated DC Motor In terms of service life or performance at its limits, it is time to apply brushless DC motors to move. The demand for brushless DC motors is unbroken - and the trend is rising. This has become koco Motion and offers an extensive BLDC program that leaves (almost) no user wishes unfulfilled. Find out a lot of interesting facts about the small electric motors here:

Contents

BLDC Motor Innovations

Intelligence in Motion from the worldwide network

Oct 21.10.2023, XNUMX | Koco Motion presents at SPS from November 14th to 16th, 2023 in Nuremberg his expertise for tailor-made drive solutions, including based on DC and BLDC motors. On this basis, the system house serves the growing demand for customer-specific drives.

Oct 21.10.2023, XNUMX | Koco Motion presents at SPS from November 14th to 16th, 2023 in Nuremberg his expertise for tailor-made drive solutions, including based on DC and BLDC motors. On this basis, the system house serves the growing demand for customer-specific drives.

Brushless DC outrunners with high power density

11.12.2019 | Brushless external rotor motors combine a small installation space with a high power density. CocoMotion presents with the BO6452N3B a new addition to the product family, which offers impressive characteristics thanks to the choice of materials and magnets. Small sizes can be used to generate power in the four-digit range.

11.12.2019 | Brushless external rotor motors combine a small installation space with a high power density. CocoMotion presents with the BO6452N3B a new addition to the product family, which offers impressive characteristics thanks to the choice of materials and magnets. Small sizes can be used to generate power in the four-digit range.

The portfolio of this brushless DC motors from Koco Motion includes drives with a diameter of 10 to 90 mm. The external rotor motors can often be equipped with HallSensors and often with Controllers and drivers. Control is simple and the external rotor motor can be customized.

The new external rotor motor BO6452N3B was designed for extreme applications in electrictools such as screwdrivers, drills or garden tools. The weight could be reduced by using high-strength aluminum. The motor also has very strong magnets. Both features lead to impressive parameters: With a diameter of 65 mm and a height of 52 mm, the DC motor delivers more than 2 kW of power.

integrated Temperature Sensors monitor the thermal behavior of the external rotor motors and thus protect them against overheating.

Customized BLDC drives with integrated electronics

19.08.2015/XNUMX/XNUMX | It's always her Lifespan, which pushes a mechanically commutated DC motor to its limits due to spark erosion and mechanical friction. However, as soon as applications require a correspondingly high running time, the brushless DC motors from Koco Motion offer an alternative because they are electrically commutated. Only the wear of slide or ball bearings still limits the service life here.

Allerdings many designers avoid the use of so-called brushless DC motors, because this is another Electronics to require their controller. The Dauchingen-based manufacturer and distributor of compact, highly integrated, electric drives and controllers now offers a solution for everyone who wants things to be simpler with its series of brushless DC motors with integrated electronics.

Iron-core motors are used, which can be controlled very easily using Hall sensors and the integrated electronics. They offer all of the advantages of a brushless DC motor. In particular with regard to anti-interference and lifespan Depending on the application, the differences are considerable compared to brushed DC motors.

DC motor as an all-round talent for countless applications

DC motor as an all-round talent for countless applications

The BLDC motors have a simple design. the integrated electronics is optimized for the respective drive. The sizes of the motors are between 16 and 90 mm in diameter and offer outputs from 0,5 to 400 W. With many versions there is a choice between the use of plain or ball bearings.

Individual design of brushless DC motors

The drive specialist adjusts the drives on request individually to the respective application. The data transmitted by the user flows directly into production as a product modification. The BLDC motor is optimally adapted to the requirements as early as the sampling phase. Modifications to mechanical components can also be made, as the focus is on customer-specific solutions rather than the production of stock items.

The drive specialist adjusts the drives on request individually to the respective application. The data transmitted by the user flows directly into production as a product modification. The BLDC motor is optimally adapted to the requirements as early as the sampling phase. Modifications to mechanical components can also be made, as the focus is on customer-specific solutions rather than the production of stock items.

The BLDC motors have a PWM (Pulse Width Modulation) Input via which speed control is possible. The frequency range is usually between 5 to 30 kHz. Motor-dependent encoder signals of 2 to 6 pulses can be sent via the output. From a diameter of 36 to 60 mm, the motors have a short-circuit brake.

BLDC motors with and without gears

The BLDC motors are also available with different gearboxes available. The smallest gear combination of this type has a diameter of 16 mm. The brushless DC motors are suitable for all start-stop and continuous operation applications. In the combination of the standardized design with large quantities, an optimal price-performance ratio can be achieved. Further applications can be found in fans, pumps, automobiles, household appliances, office machines or power tools - in short: wherever a long service life should not cost a lot.

BLDC miniature servo motor with encoder and planetary gear

17.12.2013 | Koco Motion presents a new miniature servo system consisting of a slim brushless servo motor with Encoder and planetary gear. Koco Motion has been the exclusive sales partner of for two years Constar, a developer and manufacturer of DCbell runners, brushless DC motors and customized DC motors.

17.12.2013 | Koco Motion presents a new miniature servo system consisting of a slim brushless servo motor with Encoder and planetary gear. Koco Motion has been the exclusive sales partner of for two years Constar, a developer and manufacturer of DCbell runners, brushless DC motors and customized DC motors.

The miniature servo motor measures only 12 mm in diameter and achieves a Continuous power of 1,1 W. The encoder has 256 lines, 2 channels and zero index. The planetary gear is designed for a permissible continuous torque of up to 0,2 Nm. The product portfolio of DC motors from Dauchinger now ranges from 10 mW with a diameter of 4 mm to 100 watts with a diameter of 75 mm.

The new drive system is already being used in medical devices such as the Multi-leaf collimator. In radiation therapy, the device is attached to a linear accelerator in order to adapt the treatment beam to the shape of the object to be treated.

technical articles

BLDC motor with individual control

January 09.01.2018, XNUMX | Through the electronic commutation With DC motors, depending on the application, a service life of more than 20.000 operating hours can be achieved. only the Warehouse are still subject to wear and tear.

Motor types of brushless DC motors

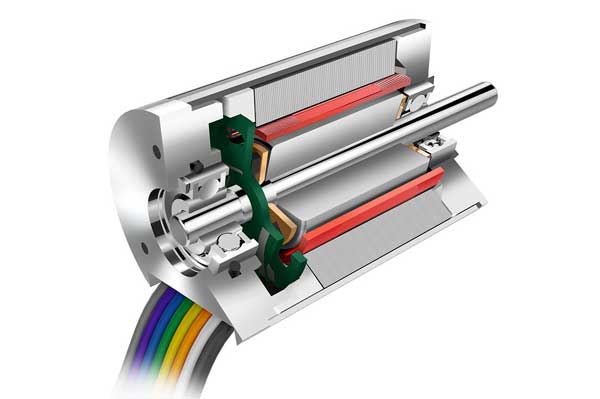

The BLDC motors are offered in two designs: as internal and external rotors. As is well known, they differ in the position of the stator and rotor: In the case of the internal rotor, the permanent magnets (rotor) and thus the rotating part are on the inside. They are surrounded by the windings, i.e. the stationary part (stator). With the external rotor BLDC motor, the permanent magnets (rotor) enclose the windings (stator). All brushless DC motors basically have a 3-phase winding.

The BLDC motors are offered in two designs: as internal and external rotors. As is well known, they differ in the position of the stator and rotor: In the case of the internal rotor, the permanent magnets (rotor) and thus the rotating part are on the inside. They are surrounded by the windings, i.e. the stationary part (stator). With the external rotor BLDC motor, the permanent magnets (rotor) enclose the windings (stator). All brushless DC motors basically have a 3-phase winding.

Inrunner BLDC motors have a higher power density, which means that a high torque can be achieved in a short space. On the other hand, the moment of inertia of the external rotor is significantly higher than that of an internal rotor of the same construction. The design used in each case ultimately depends on the space available and the performance required by the application.

Lifetime champion indoor runner

Inner runners are available in a slotted design and in a slotless design. In the slotted design, the drive specialist offers motors in the diameter range from 16 to 36 mm and with a square front flange from 42 x 42 to 110 x 110 mm. The BLDC motor winding in the unslotted stator design are characterized, among other things, by a lack of detent torque, which means that they run very smoothly and are easy to control.

Inner runners are available in a slotted design and in a slotless design. In the slotted design, the drive specialist offers motors in the diameter range from 16 to 36 mm and with a square front flange from 42 x 42 to 110 x 110 mm. The BLDC motor winding in the unslotted stator design are characterized, among other things, by a lack of detent torque, which means that they run very smoothly and are easy to control.

In addition, these BLDC motors can also be manufactured in very small designs. These are already available from diameters of 8 to 40 mm in the power range from less than 1 to approx. 150 W. Typical applications for the non-grooved version are miniature pumps, optical scanner drives, high-quality toys or sensitive positioning applications such as those in Grippers can be found.

Performance ace outrunner motor

External rotor BLDC motors offer through the special Magnet construction a very high power density in the rotor with a minimized overall length and an overall smaller, higher power volume. They are suitable for a variety of uses: In the Electromobility the outrunners are used, for example, in Drones and used as direct drives or such a brushless DC motor is used in household robots. However, a BLDC motor is also predestined for e.g. B. optical devices, actuators, blowers, suction devices and pumps.

External rotor BLDC motors offer through the special Magnet construction a very high power density in the rotor with a minimized overall length and an overall smaller, higher power volume. They are suitable for a variety of uses: In the Electromobility the outrunners are used, for example, in Drones and used as direct drives or such a brushless DC motor is used in household robots. However, a BLDC motor is also predestined for e.g. B. optical devices, actuators, blowers, suction devices and pumps.

These external rotor motors are offered in diameters from 13 to 98 mm, whereby the largest motor can already achieve outputs in the single-digit kW range. Other dimensions, sizes and customized adjustments The specialists in Dauchingen are happy to do this. And so is an integration of Controllers in the BLDC motors possible in many cases.

Individually controllable BLDC

The Controls BLDC motors can be used for sensorless motors or for motors with Hall sensors. Various electronics are available as a basis for this, which can be adapted to the drive in a customer- and/or project-related manner.

The Controls BLDC motors can be used for sensorless motors or for motors with Hall sensors. Various electronics are available as a basis for this, which can be adapted to the drive in a customer- and/or project-related manner.

For example, the Speed control from the BLDC motor via a PWM (Pulse Width Modulation) or analogue signal. The respective control voltage to be applied to the BLDC motor can be customized. In many cases, you can also work with a fixed speed or integrate the controller into the drive.

The Concepts range from simple speed control on a circuit board to the integration of, for example, membrane keyboards in the drive concept. A solution as a simple control board up to the encased solution for the switch cabinetassembly is possible at any time on request.

Electronically commutated BLDC motor with and without iron

13.02.2014/XNUMX/XNUMX | The demand for drives with a longer service life is growing in all industrial sectors. Just a year ago, Koco Motion added brushless DC motors to its portfolio. Today he already offers a range of products that almost nothing to be desired leaves.

“Brushless DC motors have been around since the late 70s, when they were mainly installed in fans. With the miniaturization of electronic components, they gradually became established in many other applications. Today they are used in large numbers wherever a long service life is important Gerhard Kocherscheidt, Managing Director of Koco Motion GmbH in Dauchingen. "We introduced them to our company last year because the market is increasingly asking for a long service life and freedom from maintenance for this type of drive," says Kocherscheidt.

Servo motor and servo amplifier predictively maintained with AI

Servo motor and servo amplifier predictively maintained with AI

The designation of brushless DC motors is versatile: Brushless DC motor, short BLDC or BL engine as well as electronically commutated motor, in short EC motor. With brushless DC motors, the mechanical contacts in the commutation, i.e. the brushes, are replaced by a contactless electronic system. This eliminates some disadvantages and drastically increases the reliability and service life of the motor, which now mainly depend on the service life of the shaft bearings.

In addition, this now maintenance-free BLDC motor does not mind if it is driven by higher speeds and short-term torque peaks become overloaded. They offer excellent properties for speed regulation and only develop low interference signals. In addition, they are suitable for operation in harsh environments. The BLDC motor is available in versions with a slotted laminated core or as a slotless design. The latter are ironless and offer numerous advantages over iron-core motors, which come with slightly higher prices: There are no cogging torques and iron losses. The rotor has a lower mass inertia, runs quieter and with less vibration and can be positioned better.

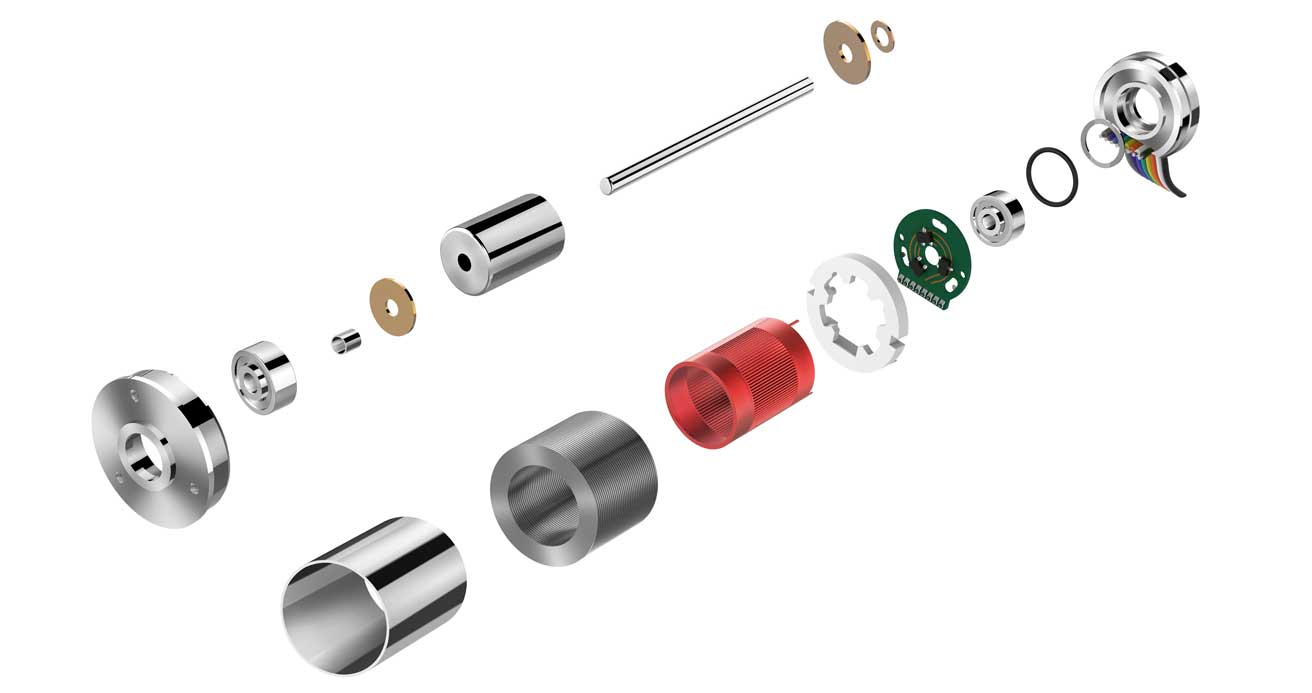

Structure and mode of operation of brushless DC motors

With brushless DC motors, the force is applied to current-carrying conductors, i.e. the commutation, no longer mechanically via the brushes but electronically. Here, the active elements are arranged in the opposite way to the brushed motor: The permanent magnets are firmly connected to the rotor or runner, while the windings are housed in the stator or stator. When an electric current flows in the windings, a magnetic field is formed in the stator, which attracts the permanent magnets in the rotor according to the polarity.

With brushless DC motors, the force is applied to current-carrying conductors, i.e. the commutation, no longer mechanically via the brushes but electronically. Here, the active elements are arranged in the opposite way to the brushed motor: The permanent magnets are firmly connected to the rotor or runner, while the windings are housed in the stator or stator. When an electric current flows in the windings, a magnetic field is formed in the stator, which attracts the permanent magnets in the rotor according to the polarity.

This creates a force that generates a torque on the permanently excited rotor. After this has aligned itself according to the magnetic field generated in the stator, the rotary movement would end. To prevent this from happening, the current flow in the windings must be switched by an electrical circuit in such a way that the magnetic field generated continues to rotate. With the EC motors, usually three phase systems employed.

Commutation of the EC motor

EC motors offer the possibility to carry out the electronic commutation depending on rotor position and speed as well as torque. There are several ways to capture rotor position and speed:

With sensorless commutation, the rotor position is detected via the counter-voltage induced in the stator coils. The rotor starts in any direction, with the electronics recognizing at the zero crossing whether it is the right direction. If that is the case, it will be further accelerated. If the motor rotates in the wrong direction, the direction of rotation is corrected and then further accelerated. This type of commutation is very well suited for continuous operation at high speeds such as those found in fans or propeller drives in model helicopters occurrence.

With sensor-controlled commutation, three offset by 120 degrees register Hall sensors the position of the rotor by giving appropriate switching signals. According to this position information, the windings that generate a torque in the rotor are controlled by the control electronics via suitable power drivers. The sensor-controlled commutation also works at very low speeds or when stationary. With this commutation, with three or more phases, not all phases are usually energized at the same time. At least one phase remains de-energized here at all times. With this principle, highly dynamic drives can be implemented and the speed can be controlled. Positioning is only possible with the coarse resolution of the Hall sensors. The sensor-controlled commutation is predestined for use in small pumps, scanners or propeller drives, for example.

DC motor as an all-round talent for countless applications

DC motor as an all-round talent for countless applications

Another principle is that Commutation via Hall sensors together with high-resolution encoders: This version requires a more complex controller with a position controller. With her it can be very precisely according to the Encoder Position the resolution and control it as highly dynamically as with a servo drive. Applications for this most complex type of commutation can be found, for example, as positioning drives in microscopes and medical equipment as well as in card readers.

The is ideal for demanding applications vector scheme on. In contrast to operation on a three-phase network, the rotor position does not passively adapt to the voltage and torque, but the voltages of all phases actively to the rotor position and the desired torque. For this purpose, all phases are controlled with a sinusoidal voltage and energized at the same time.

Perfectly happy BLDC portfolio

In recent months, Koco Motion has successively expanded its range of brushless DC motors and now offers electronically commutated DC motors with a slotless stator and iron-core BLDC motors. The partners with whom the Dauchinger drive specialists work together show just how diverse the portfolio is: "We have concluded exclusive contracts with exclusively certified companies such as Constar, Hengdrive, Dinko and yunkong as well as a cooperation with leadshine. Our current product range offers solutions for most of all applications," says the managing director.

Ironless DC motors

“One of our newest products is a Miniature servo system, consisting of a slim brushless servo motor with encoder and planetary gear“, the managing director refers to the innovation presented for the first time at the last SPS IPC Drives. The miniature servo motor is only 12 mm in diameter and achieves a continuous output of 1,1 W. The Encoder has 256 lines, 2 channels and zero index. The planetary gear is designed for a permissible continuous torque of up to 0,2 Nm. The new drive system is already being used in medical devices such as the multi-leaf collimator - a device that is attached to a linear accelerator in radiation therapy in order to adapt the treatment beam to the shape of the object to be treated.

BLDC motor for smooth running and long runtime

BLDC motor for smooth running and long runtime

The portfolio of the manufacturing partner Constar, a developer and manufacturer of DC bell rotors, brushless DC motors and customer-specific DC motors, now comprises eleven series and ranges from 10 mW with a diameter of 4 mm to 100 W with a diameter of 75 mm. The idle speeds are 4000 to 50.000 rpm-1. The coreless or slotless BLDC motors are available with mechanical and electronic commutation. The brushless DC motors with a slotless stator are mostly designed with 3 phases. They are available with and without Hall sensors. In the version without the Hall sensors, the electromagnetic force (EMF) is used to detect the speed.

If they are equipped with Hall sensors and/or encoders, they are suitable for applications that require a Reversal of speed and direction of rotation require as well as for positioning. Apart from medical devices, such brushless DC motors can be found in instrument making, electrical tools, small household appliances, and model airplanes and ships.

Iron-tinged DC motors

The iron armature BLDC motor program comes exclusively from the Chinese manufacturer hengdrive. It includes ten models in the diameter range from 16 to 68 mm and lengths from 18 to 72 mm. The nominal voltages of 6 to 48 V and 220 V AC enable output powers of 0,5 to 67 W. Equipped with integrated electronics for continuously variable speed control from 0 to 100% by means of a PWM (pulse width modulation) or via the encoder signal the BLDC motors are reversible.

In addition, the mostly 3-phase drives have a Quick brake function and offer high efficiency. Thanks to the simple construction, the Hengdrive motors are very inexpensive. In addition, they offer a long service life of more than 10.000 operating hours and, being EMC-friendly, have virtually no electromagnetic interference. They simply work by reversing their direction of rotation and run with very little noise and vibration. Dinko's iron core BLDCs complete the range. With flange dimensions of 42 to 130 mm, they offer outputs from 20 to 500 W and are all equipped with Hall sensors and ball bearings.

The application possibilities for the iron armature BLDC motors are unimaginably versatile: For example, they are suitable for small drive tasks in household, medical and personal care devices. The list can be continued numerously with applications in automotive, office technology, instrumentation, pumps, fans or security and monitoring systems as well as the computer technology.

BLDC motor drives drone - video

You might also be interested in...

Koco Motion | System house for drives

DC motor and other drives for medical technology

Stepper motor linear actuators galore

Linear motor | With linear actuator and electric cylinder

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.