First artificial intelligence image recognition for CAE software

- Details

- Hits: 9082

The new CAE software Odyssey A-Eye from Hexagon (MSC Software) gives users without expert knowledge access to powerful digital twins Artificial intelligence (AI) applications. These require less input data and use image recognition to predict behavior. Odyssey is based on machine learning and performs parametric design and optimization in real time.

Contents

- CAE Tool uses AI to improve computer-aided engineering

- Artificial intelligence integrated in CAE calculation

CAE Tool uses AI to improve computer-aided engineering

25.10.2021: hexagons Manufacturing Intelligence Division introduces the CAE software Odyssee A-Eye. The new CAE tool uses AI to improve computer-aided engineering (CAE) for a large number of Industries. Complex CAE preparation and expert knowledge in the field of simulation are dispensed with.

Thanks advanced pattern recognition Odyssee A-Eye analyzes images, photos, videos and simple data sets for machine learning (ML) in the context of engineering simulations. Because of its ability to map existing CAD simulation data and provide like-for-like forecasts for a specific problem, this computer-aided engineering tool is invaluable for any conceivable design.

Solidworks 2022 | CAD software by and for users

Solidworks 2022 | CAD software by and for users

Engineers determine design optimization, cost creation or the required production time for a new product without labor-intensive model preparation, Specialist knowledge or the definition of boundary conditions for the simulation.

Applying ML processes engineering problems usually requires special knowledge and large amounts of training data in order to deliver valid and reliable results. This puts ML out of the reach of smaller companies and non-experts. With Odyssee A-Eye, complex data models are no longer necessary.

Application examples of the CAE software

The CAE software enables users to relate their problem to training data from Hexagon's simulations by entering readily available CAD files, images or scalar data. With the CAE tool, designers, production engineers, machine operators and other simulation laypeople get powerful functions for digital twins at hand. Even non-simulation experts make data-based engineering decisions and interactively investigate problems with results in almost real time.

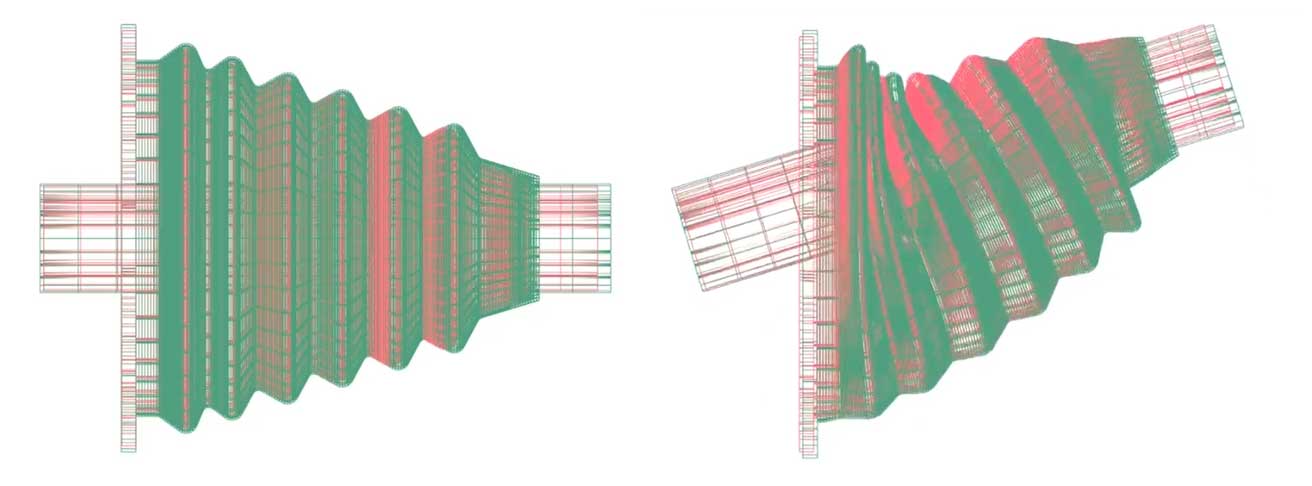

Simulation of vehicle wheels

The behavior of different vehicle wheel designs in the case of obstacles such as curbs or foreign bodies is examined. With non-linear Finite element simulations (FEM) engineers create a database with different configurations such as design or number of spokes. In this way, you take into account the effects of different designs. AutomobileDevelopers can now use this data to understand the behavior of a wheel - without engineering or CAE knowledge based on a pure 2D image.

Intelligent CNC control for new + old machine tools

Intelligent CNC control for new + old machine tools

Calculation of the lift of aircraft wings

The calculation of lift and drag coefficients for new wing profiles of aircraft on the basis of a 3D image of the new design is another possible application. It is done using a database of only 16 Wing profile simulations from the established definitions of the National Advisory Committee for Aeronautics (NACA). As a rule, this process takes a few days and takes the time and attention of a CAE analyst and requires several simulation tools.

Manufacturing time of a component for the machine tool

The use of Odyssee A-Eye enables a process mechanic to determine the production time of a component with a specific CNC machine tool and a specific Metal to predict. For this he only uses the database and a 3D-Step file. The valuable process knowledge acquired in this way can also be used for better production planning or the optimization of the quotation process. With the simulation of manufacturing processes, the same method can be used to forecast dimensional tolerances or the strength of connections.

CAE software fits seamlessly into customer processes

Engineers with no knowledge In the ML area, Odyssee can use A-Eye to develop their own robust AI applications for any problem. Be it for the optimization of a tire profile design or the error analysis of computer chips. These findings can then also be made available to others.

Ergonomic computer workstation in the office and home office

Ergonomic computer workstation in the office and home office

The new platform integrates all computer aided engineering solutions from Hexagon and fits seamlessly into existing customer processes a. In addition, industries are now also benefiting from Artificial Intelligence that they previously did not consider practical for their design requirements.

Thanks to their accessibility, that will be CAE tool also used by companies that do not have CAE specialists or who want to use the existing expertise to solve other problems or for the final design validation. With Odyssee A-Eye, an engineer can specify an application for design optimization, then make it available to the design team and let the operating staff execute it.

Statement by Roger Assaker

“AI is an invaluable tool in design and engineering because it takes virtual engineering to the next level. Thanks to AI, labor-intensive design tasks that previously took days or even weeks can be completed in minutes or hours without the simulations losing their accuracy, "explains Roger Assaker, President Hexagon Business Unit Design and Engineering Software. "In addition, the user-friendly design of the CAE software simplifies its integration into modern development practices. Even inexperienced users can use these sophisticated procedures and benefit from results in a particularly accessible format."

Artificial intelligence integrated into CAE calculation

27.06.2019: MSC Software expands its collaboration with CAD LM. Both companies want to further develop the new software package "Odyssey" in a strategic partnership. It is based on machine learning and performs parametric design and optimization in real time. The Paris-based company CAD LM is a pioneer in the implementation of artificial intelligence (AI) in CAE. MSC has included the solutions globally in its product portfolio.

27.06.2019: MSC Software expands its collaboration with CAD LM. Both companies want to further develop the new software package "Odyssey" in a strategic partnership. It is based on machine learning and performs parametric design and optimization in real time. The Paris-based company CAD LM is a pioneer in the implementation of artificial intelligence (AI) in CAE. MSC has included the solutions globally in its product portfolio.

CAD LM developed predictive real-time models for design optimization based on CAE simulations. These are based on machine learning technologies from the Odyssey software range. The combination of information from CAE calculations with mathematical models and data mining means that highly complex, highly non-linear simulation applications such as crash, transient dynamics and structural calculation, CFD - but also finance, biomechanics and armament applications - can be analyzed very quickly.

Schaeffler invests in artificial intelligence

Schaeffler invests in artificial intelligence

Odyssey is a platform with various options for machine learning, data handling, signal processing, image processing and recognition, data compression and merging as well as system sensitivity analyzes. The functions are through Optimization and robustness indicators added. The software can be used for FEM or CAD models and is independent of the solver. As a result, Odyssey can be coupled and used with many CAE solutions from MSC without any effort: from the preliminary design to optimization and robustness assessment.

You might also be interested in...

Artificial Intelligence | trends and developments