Thermoplastic polyimide for high temperature applications

- Details

- Hits: 8701

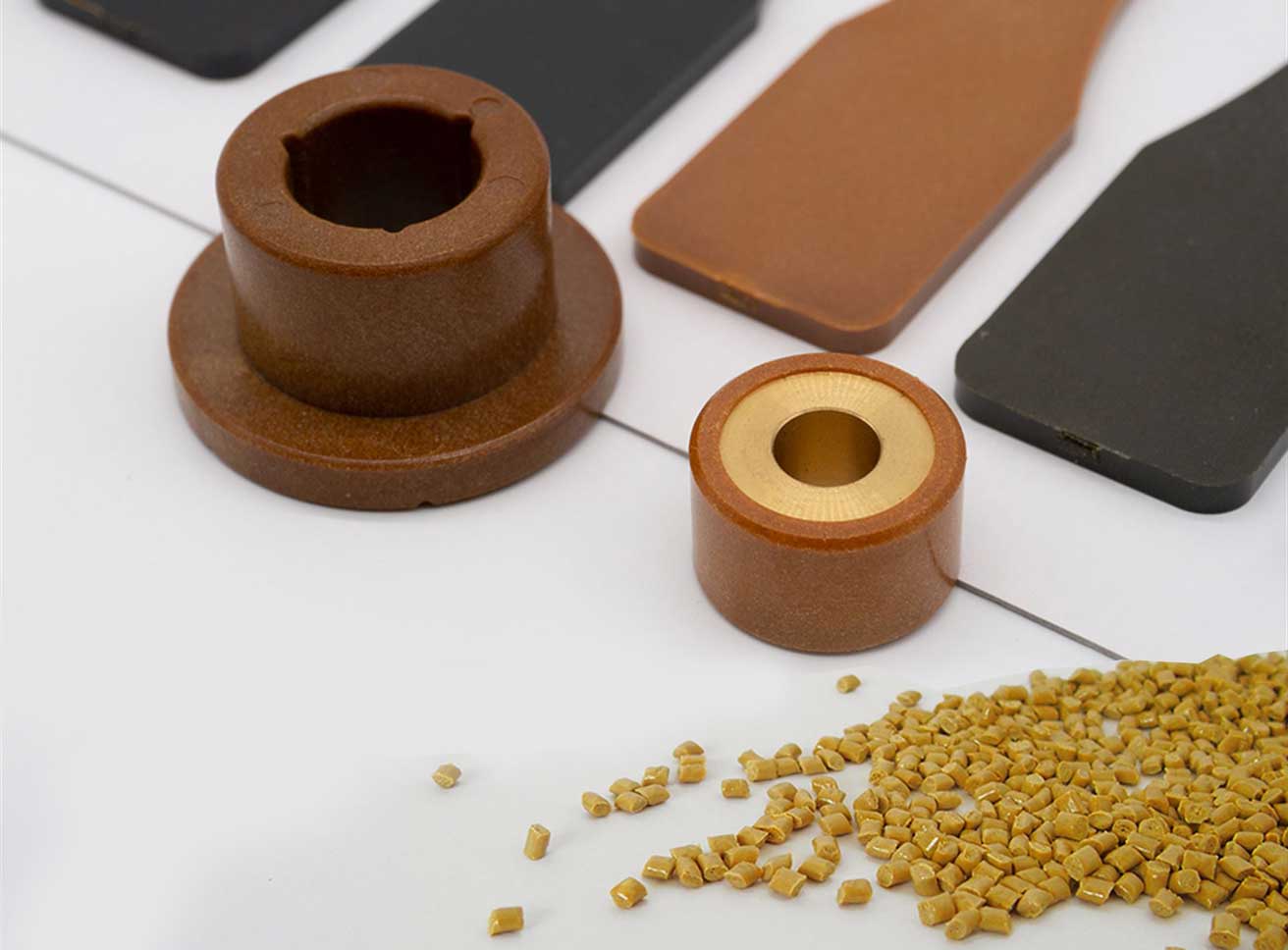

The thermoplastic Polyimide Aurum is a highly heat-resistant super-engineering Plastic with high production efficiency in injection molding. The thermal plastic challenges the conventional wisdom that polyimide performs very well but is difficult to process. As a distributor for PI Meldin from Saint-Gobain, Bieglo presents the PI portfolio, which is also suitable for the 3D pressure suitable.

The polyimide Aurum is the only thermoplastic polymer (TPI) with a Glass transition temperature Tg of 245 ° C. This makes it ideal for use at high temperatures. In powder coating for insulation and wire coating in the Electronics the polyimide leaves other polymers such as PEEK and PTFE behind.

Additive manufacturing for 4K 3D printing, space and Industry 4.0

Additive manufacturing for 4K 3D printing, space and Industry 4.0

The melt-processable aurum is suitable for processes for the production of Injection molding and extrusion. With its properties such as high temperature stiffness over 150 ° C and the possibility of fiber reinforcement (E-module 3> 22 GPa), Aurum can even be processed better than PEEK. The polyimide is therefore used in Automotive industry. Thrust washers, sealing rings, bearing holders and Warehouse are made from it. In the aircraft industry it is used for structural components of aircraft engines.

Polyimide with variable expansion coefficient

The Expansion coefficient of the Compounded Aurum is controllable. With these properties, Aurum is also suitable for pistons, oil pumps and oil seals in Construction. The polyimide offers the highest critical PV value of all thermoplastic resins in an unlubricated sliding atmosphere. This property is useful in applications such as bearing holders, thrust washers or seals.

Layer thickness measurement ensures quality in powder coating

Layer thickness measurement ensures quality in powder coating

The excellent creep and chemical resistance as well as the resistance to car fuel and lubricants, aviation fuel and cleaning agents also make Aurum predestined for use in oil pumps and components for aircraft engines. The super plastic is also suitable as a Material for 3D pressure.

General technical knowledge

What is aurum

Aurum is a TPI resin from the group of thermoplastic polyimides that can be melt-processed and is suitable for manufacturing processes such as injection molding and extrusion. With continuous use temperatures of up to 240 ° C, components made from the Aurum resin family are an excellent replacement Metal, Ceramics and other plastics.

What is a polyimide?

Polyimides (PI) are Plastics with properties such as high strength, very high rigidity and low notched impact strength and they offer good wear and sliding behavior. PI is lighter than metal and easier to bend than ceramic. The continuous use temperature is 240 ° C. At temperatures above 150 ° C, PI is stronger than an aluminum alloy. Polyimides are used as thermoplastics and less often than thermosets, especially in electrical applications in the form of foils.