Micro injection molding made of technical ceramics for endoscope tip

- Details

- Hits: 5838

Sembach Technical Ceramics has recently been producing small parts in Micro injection molding Method. Micro injection molding is not yet very common in the ceramic industry. Manufacturers of medical technology often still lack the knowledge about the materials of the Technical ceramics. However, these offer a number of positive properties. This makes them particularly suitable for miniature components in medical technology.

Micro injection molding is used for components weighing between 0,01 and 0,5 g. Some parts are so small that they only with the help of a magnifying glass are recognizable. Micro injection molding differs from classic injection molding in that it has a very small injection unit. This is integrated in the injection molding machine instead of the normal sized unit.

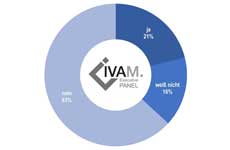

Microtechnology expectations regarding corona crisis

Microtechnology expectations regarding corona crisis

This micro injection molding Injection unit is based on a different technology than normal injection molding technology. A piston press is used instead of the usual screw shaft. The piston is so small that it can carry very small amounts of material. It is important to monitor the process. With the small injection unit, the minimal piston movements can be scaled and the smallest quantities can be measured and monitored.

Technical ceramics for medical devices

Parts for Medical devices are predestined for the micro injection molding process. The manufacture of medical components is subject to sensitive requirements, especially when it comes to components that are in direct contact with Body tissue stand. The material is suitable for this Ceramics, usually oxide and non-oxide ceramics, because they are particularly biocompatible, corrosion-resistant and wear-resistant. Typical small parts made from micro injection molding are, for example, miniature feedthroughs for tips for endoscopes for minimally invasive procedures, cardiac pacemakers or tools for miniature components.

1 mm² image sensor enables the world's smallest digicam

1 mm² image sensor enables the world's smallest digicam

IATF 16949 certification

Sembach fulfills the strict regulations of the micro injection molding process Certification according to IATF 16949. For example, the company manufactures miniature bushings for pacemakers. The volume of this part is 13,9 mm3. It weighs only 0,055 g. Quality control following the manufacturing process of the micro parts can be carried out at Sembach, depending on the number of items, by visual microscope inspection or automatically as an optical 100 percent inspection with camera systems.