rectifier | Electronic components for direct current converters

- Details

- Hits: 6523

Rectifier, the electronic components for DC converter, are essential in electrical engineering because they convert alternating current into direct current. This article highlights current new developments on the market, shows application cases and takes a look back at the evolution of this technology. The focus is on the advanced technologies and materials that significantly improve the efficiency and performance of modern rectifiers.

Contents

- Rectifier 2024 – The most important things in brief

- Rectifiers and DC converters innovations

- The hot cathode rectifier: A milestone in the history of electronics

- FAQ

Rectifier 2024 – The most important things in brief

Converting alternating current to direct current is one Basic requirement for the operation of countless electrical devices that require electrical power. The level of development of rectifiers and direct current converters has made significant progress in recent years, characterized by innovations in semiconductor technology and increases in efficiency. Modern rectifiers use advanced materials such as silicon carbide (SiC) and gallium nitride (GaN), which enable higher performance, improved thermal properties and lower energy losses.

These developments not only expand the areas of application in industry, energy supply and portable devices, but also contribute to Sustainability and Energy Efficiency at. Trends such as miniaturization and the integration of intelligent control systems promise to further optimize the performance and flexibility of rectifier systems. The current focus is on improving reliability and reducing costs to make these essential electrical engineering components accessible to a wider range of applications.

Rectifiers and DC converters innovations

Below we will introduce you to the new developments in the area of rectifiers and direct current converters:

Rectifier optimizes energy supply quality

05.03.2024/XNUMX/XNUMX | In the real world of Energy supply The ideal sine curve of the alternating voltage often deviates due to harmonic voltage distortions caused by real consumers. These distortions, which occur as integer multiples of the fundamental frequency, combined with higher-frequency voltage distortions, represent a growing challenge for our power grids.

05.03.2024/XNUMX/XNUMX | In the real world of Energy supply The ideal sine curve of the alternating voltage often deviates due to harmonic voltage distortions caused by real consumers. These distortions, which occur as integer multiples of the fundamental frequency, combined with higher-frequency voltage distortions, represent a growing challenge for our power grids.

The increasing burden of these disorders poses the risk of one electrical disaster, a condition in which the power grid is severely affected by excessive disturbances. The problem: Every self-commutated power converter installed in the network feeds the clock frequencies of its built-in power electronics into the network as supra-harmonic interference.

Prevent network infarction in good time

Would you like a threatening one? Network infarction To counteract this, the network must be dampened by an additional ohmic resistance. This is because interactions are becoming increasingly pronounced due to the immensely increasing proportion of non-ohmic consumers in our networks.

Frequency inverter | decentralized, networked with app and much more.

Frequency inverter | decentralized, networked with app and much more.

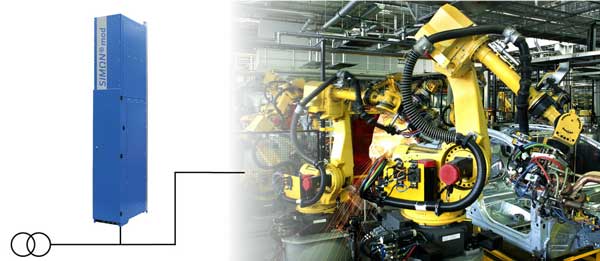

The rectifier SimΩn from Capacitor dominite sets new standards in the quality of energy supply. As an active, modular rectifier, SimΩn uses advanced and low-loss semiconductor technology based on silicon carbide. This innovative technology makes it possible to attenuate the energy supply networks across a broad spectrum and efficiently reduce interference levels, while at the same time offering low-loss and highly dynamic reactive current compensation.

Broadband filtering over a wide frequency range

SimΩn is particularly in demand where broadband filtering over a wide frequency range is necessary. By simulating the behavior of a resistor for all frequencies except the fundamental, the rectifier can eliminate resonances and reduce voltage levels across a wide range without converting the active power consumed into power loss. Instead, the energy is extracted from the harmonics and fed back into the network as fundamental active power. The patented control process enables effective local energy recycling.

This innovative approach from SimΩn sets new standards in the Quality of energy supply and offers a sustainable solution to address the increasing challenges in our power grids. With its patented technology, SimΩn makes a decisive contribution to stabilizing the grid and ensuring a reliable and efficient energy supply for the future.

DC converter for DC speed and current control

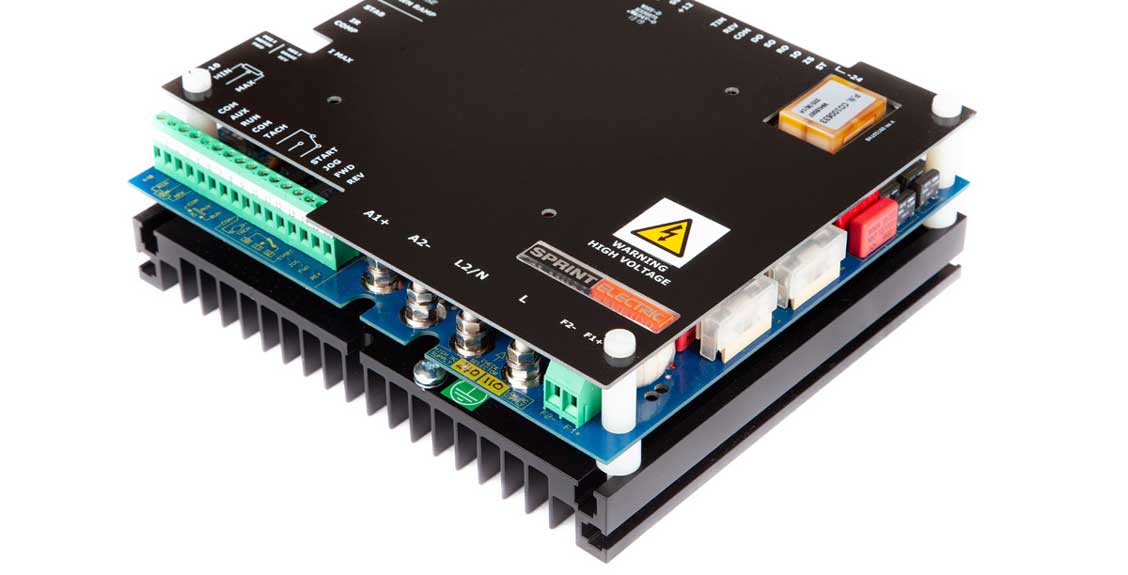

25.11.2019 | Sprint Electric has modified its 3200i and 3600XRi series DC converters. The innovations in both inverter series increase the adaptability, performance and longevity of the two- and four-quadrant DC controllers. Both versions can be used for speed and current control of most brushed DC motors .

In addition to DC power converters with an open design and rectifiers that can be mounted on DIN rails, Sprint Electric now also offers a version with Cover plate at. It is designed so that the overall height and other dimensions of the power converter remain unchanged. Thanks to the PCB material used, the cover plate is robust and shockproof and offers additional protection for users and components.

The black base color of the rectifiers and the white assembly print applied via screen printing make it easier to identify the setting options and connections. The new cover plate ensures user-friendly and space-saving installation of various components.

Network-capable frequency converters for the smart factory

Network-capable frequency converters for the smart factory

These include additional analogues PID controller, external linear ramps or high-precision differential or summing amplifiers. This significantly increases the performance of the controller. The solder eye connections were converted into connection terminals.

The key figures from the DC converter

The DC converters of the 3200i series cover nominal currents for applications from 8 to 48 A at DC voltages from 110 to 440 V (optionally 30/60 V). The 3600XRi series is designed for nominal currents of 4 to 36 A with a supply voltage of 110 to 440 V (optionally 30/60 V).

The hot cathode rectifier – a milestone in the history of electronics

The world of electronics has evolved significantly thanks to innovative technologies such as the hot cathode rectifier. This Electron tube, a diode with two electrodes, uses the principle of one-way conduction of current. The special feature lies in the glowing cathode, which becomes positively charged when an alternating voltage is applied and thus emits electrons. This process allows current to flow in only one direction, resulting in efficient rectification of AC to DC current.

The world of electronics has evolved significantly thanks to innovative technologies such as the hot cathode rectifier. This Electron tube, a diode with two electrodes, uses the principle of one-way conduction of current. The special feature lies in the glowing cathode, which becomes positively charged when an alternating voltage is applied and thus emits electrons. This process allows current to flow in only one direction, resulting in efficient rectification of AC to DC current.

The hot cathodes in these rectifiers are available in two options: heated directly and indirectly. In direct heating, the heating wire forms the cathode formed by the heating wire itself. The heating conductor consists of a wire or tape and is stretched or coiled between springs. With indirect heating, the cathodes are heated by a separate, electrically insulated heating circuit with a tungsten filament.

The Ceramic insulated coil is located in a metal tube, often made of nickel, which is provided with the oxide cathode layer. This innovation enabled wide application in electronics, from lighting technology such as in arc lamps or headlights, to battery charging and, above all, in broadcasting technology.

Siemens rectifier from 1938

A historical example of this technology is the Siemens-Cleaner hot cathode rectifier type V 230, 501 No. 332031 from 1938, which was designed for an operating voltage of 110 kV. With a maximum voltage of 230 kV and a heating voltage that could vary between 12,8 V and 14,8 V, this model represents an important milestone in the development of electronic components.

Tube diodes with hot cathodes were previously also used in tube-equipped devices, such as the so-called People's Receiver with the tube VY2, used as a rectifier and demodulator diode. The technology behind this rectifier formed the basis for later developments and was only superseded by advances in semiconductor technology, particularly selenium and silicon diodes.

The history and technical evolution of the hot cathode rectifier underlines the importance of innovation in the electronics industry. This technology not only laid the foundations for modern electronics applications, but also paved the way for future developments. He has insights into this technology VDE Leipzig/Halle given last year as part of its general opening day.

Frequently asked questions

What does the rectifier do?

A rectifier converts Alternating current (AC) to direct current (DC). This process is essential for electronic devices that require direct current even though the power grid supplies alternating current. By using semiconductor diodes or thyristors, the rectifier allows current to flow in only one direction, resulting in the conversion of AC to DC.

When do you need a rectifier?

You need a rectifier when a device or circuit requires direct current (DC), but only Access to alternating current (AC) from the power grid. This is the case with many electronic devices, from cell phone chargers to computers to industrial control systems.

Is a diode a rectifier?

Ja, a diode can act as a rectifier. It allows current to flow in only one direction and thereby converts alternating current (AC) into direct current (DC), albeit in its simplest form.

What is the difference between rectifier and inverter?

A rectifier converts alternating current (AC) into direct current (DC). An inverter, on the other hand, converts direct current (DC) into alternating current (AC). So the main functions of rectifier and inverter are these conversion from AC to DC vice versa.

How does rectification work?

Rectification works by generating alternating current (AC) in one direction forces to generate direct current (DC). This is done by using diodes that only allow current to flow in one direction. Half-wave rectification uses only one half-wave of the AC, while full-wave rectification uses both half-waves to achieve more efficient conversion.

What does a rectifier circuit do?

Rectifier circuits convert alternating current (AC) to direct current (DC). you use Diodes or other semiconductor devices to limit the current flow to one direction (half-wave rectifier circuit), resulting in the conversion of the input alternating current into an output direct current.

What is the difference between direct and alternating current?

Electricity, the invisible force that powers our world, presents itself in two basic forms: direct current (DC) and alternating current (AC).

The key difference lies in the way energy flows through conductors. Direct current, symbolized by a constant, unidirectional flow direction, is the form of current that characterizes batteries. It is ideal for portable devices and electronic circuits as it ensures a stable power supply.

Alternating current, on the other hand, periodically changes direction and strength, a principle that has revolutionized our homes and industries by making the transport of energy over long distances more efficient. This dynamic nature of alternating current allows it to be easily transformed to meet different voltage needs, making it the preferred choice for the public power grid.

You might also be interested in...

LED machine lights in IP54 + IP67 for harsh environments

Circuit boards for ventilators in times of the corona crisis

Electro casting resins reliably cool electrical and electronic components

KTR Systems | Made for movement

Jens Struck is a business owner, journalist and web designer at German Online Publisher GbR in Ried.