PET fitting elements for assembly of composite assemblies

- Details

- Hits: 4885

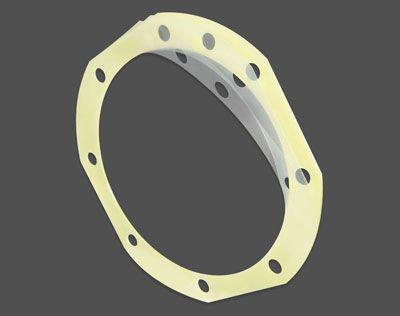

The construction of assemblies from fiber composite components follows its own rules. The key factor here is the design of high-precision connection points, which enable the lightweight components made of glass or carbon fibers to be assembled without stretching during subsequent assembly. The peelable PET fitting elements of the product line "M-Tech L" from Martin are tailor-made for this task.

The construction of assemblies from fiber composite components follows its own rules. The key factor here is the design of high-precision connection points, which enable the lightweight components made of glass or carbon fibers to be assembled without stretching during subsequent assembly. The peelable PET fitting elements of the product line "M-Tech L" from Martin are tailor-made for this task.

Designers specializing in composite assemblies must be very specific about the design of non-positive joints or gaps and distances. Because the later mechanical compensation, z. B. by grinding on lightweight materials such as glass fiber or carbon fiber would be extremely problematic. In addition, these materials are less tolerant to stress-related strains that occur during assembly - such as by tightening the sealing surfaces of joints. However, both problems can be ruled out right from the start if the PET shims (Peel shims) of the M-Tech L product line are incorporated in the design.

These polymer compensation elements consist of extremely thin, fully laminated PET films, which can be individually peeled off individually. They are offered in various overall thicknesses of, for example, 1,0 mm and 2,0 mm, whereby the manufacturer tailors the geometry and the bores of the fitting elements precisely to the lightweight construction of the customer. This also applies to the thickness of the individual peel-off films: Depending on the requirement for the matching accuracy, they can be 0,2, 0,1, 0,05 or only 0,025 mm thick. As a result, for example, a PET shim M-Tech L with a nominal size of 1,0 mm contains exactly 20 peelable foils of thickness 0,05 mm. Visible are the different thicknesses of their different colors. It ranges from semi-transparent to dark red to yellow and transparent.

PET shims as process solution

Integrated by the designer in the drawing of the assembly and listed in the parts list, process-specific sets of M-Tech L PET liners can be assembled and provided for assembly. Ideally, these sets are matched exactly to those joints of the assembly according to the principle: "One joint-a spacer element", which has to be processed by the respective fitter at his workplace or in his process step.

Integrated by the designer in the drawing of the assembly and listed in the parts list, process-specific sets of M-Tech L PET liners can be assembled and provided for assembly. Ideally, these sets are matched exactly to those joints of the assembly according to the principle: "One joint-a spacer element", which has to be processed by the respective fitter at his workplace or in his process step.

Similarly, the user of the composite assembly can also equip his service or maintenance team with a suitable set of PET liners. This ensures that the correct shims with the correct nominal dimensions and the correct film thickness are always at hand in case of repair or maintenance. The peeled PET films can be reused if the assembly should show unforeseen subsidence phenomena.

Ideal solution for lightweight construction

Due to their material polyethylene terephthalate, the laminated fitting elements of the M-Tech L product line are suitable for cost-effective tolerance compensation in the CFRP and GRP assemblies of automotive, aviation or e-mobility. They offer good mechanical properties, are very light and therefore fit well into the material structure of the lightweight structures. In addition, they are resistant to corrosion and their density of 1,3 kg / dm3 corresponds very well with the objectives in lightweight construction. M-Tech L PET liners can be used for operating temperatures up to 80 ° C.

When used in metallic assemblies - such as gears or Rolling-Constructions – the discs can offer further advantages. These include, for example, electrical and thermal insulation and the associated avoidance of electrochemical contact corrosion. Thanks to some detailed optimizations, the interlayer specialists in Dietzenbach were once again able to significantly improve the manual peelability of the PET shims. A matching paring knife is also provided.

You might also be interested in...