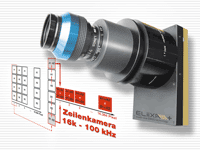

High resolution line scan camera with 16k resolution

- Details

- Hits: 8654

In camera technology for industrial image processing, ever higher resolutions and speeds are required due to ever smaller structure sizes. The finest details have to be checked while the number of cycles increases. Line scan cameras must be able to keep up with this. With the "Eliixa +" line camera from e2v, not only speed problems can be solved.

In camera technology for industrial image processing, ever higher resolutions and speeds are required due to ever smaller structure sizes. The finest details have to be checked while the number of cycles increases. Line scan cameras must be able to keep up with this. With the "Eliixa +" line camera from e2v, not only speed problems can be solved.

The imaging ratios in line camera applications are usually chosen that the pixel resolution is both along the line as well as in the transport direction is equal to. If you increase the horizontal Resolution, is also the resolution in the transport direction speak the Increase line rate. This connection prevents in some applications the use of the highest resolution Line cameras. So in some fast applications, for example, three 4k line scan cameras with up to 72 kHz installed, as a 12k line scan camera with maximum 25 kHz only running. The multi-camera solution is so by about factor 3 faster than the solution with only one line camera. For high Resolutions of 8k, 12k and more pixels / line is thus a significant increase of Line rate required to such applications to implement with just one camera.

With the rising speeds inevitably stands less and less Time for the exposure available. The is the photosensitivity of the sensor must also be increased. One solution to the problems described is the new "Eliixa +" line scan generation from e2v with multi-line CMOS architecture.

Vision Sensor solves many tasks in factory automation

Vision Sensor solves many tasks in factory automation

The newly developed CMOS sensor has 16.384 pixels with a maximum Line rate of up to 100 kHz read out become. With 5 μm pixel size is the Sensor also easy to handle in terms of optics. The MTF (Modulation Transfer Function) is with existing today Optics high and will not go through a too small pixel size restricted. The manufacturer reaches in its own production process a good planarity of the sensor, so a sharp picture about the entire sensor length of 82 mm ensured at a hunt.

The structure of the multi-line CMOS sensor ensures a wide dynamic range from up to 73 dB: before the analog-to-digital conversion is through the Design of the photodiode achieved a high charge conversion factor. The amplifiers are right next to the active pixels arranged. This leads to a high quantum efficiency (QE) of up to 72% on 550 nm. The Correlated Double Sampling (CDS) ensures homogeneous, low-noise Images.

The sensor's special multi-line architecture consists of four active lines each 16k pixels that are next to each other without spacing lie. Two adjacent each Lines form a line pair, the noise-free the analog voltages added. The two intensity values, the after the AD conversion of each row pair are present then digitally in FPGA sums up. This combined process the addition of analog voltage and digital brightness values increases the sensitivity of the sensor by factor 4. This sensor is with his 450 LSB / (nJ / cm2) sensitive enough also in practice without expensive Special lighting the highest Speed to drive.

3D Camera | Industrial image processing

3D Camera | Industrial image processing

Because the four sensor lines are right next to each other lie, the picture sharpness remains - in Unlike line scan cameras with more lines or with spaces between the lines - even with the oblique view of up to 45 ° full on the object. Due to the high popularity of Camera Link, there is the line scan camera with "Camera Link Full Interface". The full speed is achieved with "Coax" press.