Position sensor for special effects in large blockbuster cinemas

- Details

- Hits: 5215

What does a 12 meter long boat deck and a thestral-drawn carriage in Fantastic Beasts 2 or Murder on the Orient Express have to do with one Position sensor from Siko to do? Even if these objects are more exciting than sensors for position detection, the draw-wire encoder for being in Marvel Studios and Warner Brothers blockbusters can special effects even more accurate and authentic. Read exactly how to do this:

Contents

- Accurate and authentic special effects

- Integrated pull-wire encoder in the hydraulic cylinder

- Externally mounted position sensor

- Simple connection of the draw-wire encoder

- What is a cable encoder?

Accurate and authentic special effects

are position sensors Measurement Technology Components that are not necessarily to be expected in a film production. However, cable pull sensors from Siko are used here Absolute moco. The British company develops and builds the hydraulic studio environment for special effects in film productions. Along with partner David Watkins, Special Effects Supervisor absolute effects, Andy Ryan wanted to make the movement of special effects in the film industry even more precise and authentic. Because he considered the special effects in Great Britain as outdated in this respect.

are position sensors Measurement Technology Components that are not necessarily to be expected in a film production. However, cable pull sensors from Siko are used here Absolute moco. The British company develops and builds the hydraulic studio environment for special effects in film productions. Along with partner David Watkins, Special Effects Supervisor absolute effects, Andy Ryan wanted to make the movement of special effects in the film industry even more precise and authentic. Because he considered the special effects in Great Britain as outdated in this respect.

"We specialize in creating the conditions for the motion control of certain motion sequences in film applications, in moving base platforms and in sets," comments Andy Ryan. "We act as a link from VFX to the physical world and have developed a reliable HMI and software package for film production.

We still use open-loop systems for some of the shooting. But mostly we prefer systems with closed loopto ensure the positioning and reliability that is critical in today's film production. The use of absolute encoders from Siko gives us the opportunity to repeat the recordings over and over again. This means: We can work safely, stop safely and record positions at any time. This technique has taken the physical side of special effects to a new level and it only gets better with time.”

Integrated pull-wire encoders in the hydraulic cylinder

Particularly hydraulic movements make demands if they appear natural and are to be carried out in a physically safe manner. Various draw-wire encoders from Siko are used here to determine the position of the Hydraulic Systemdetermine the cylinder. The robust position sensors are compact and can be used in the tightest of spaces.

Inductive sensors for logistics and carbon applications

Inductive sensors for logistics and carbon applications

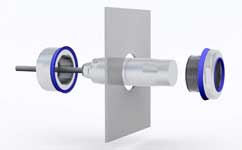

For example, for scenes in Grindelwald's crimes from the Fantastic Beasts series, the SGH10 draw-wire encoder offers a patented feature: Direct integrated in the hydraulic cylinder the sensor immediately measures the position or extension of the cylinder. Thanks to the integrated design, the position sensor is protected from external influences. In addition, the piston does not have to be as with the alternative magnetostrictive Sensors be hollow drilled so that the draw-wire encoder can be integrated. This omitted work step is also eliminated in terms of costs with the integrated position sensor.

Position sensors record position and speed

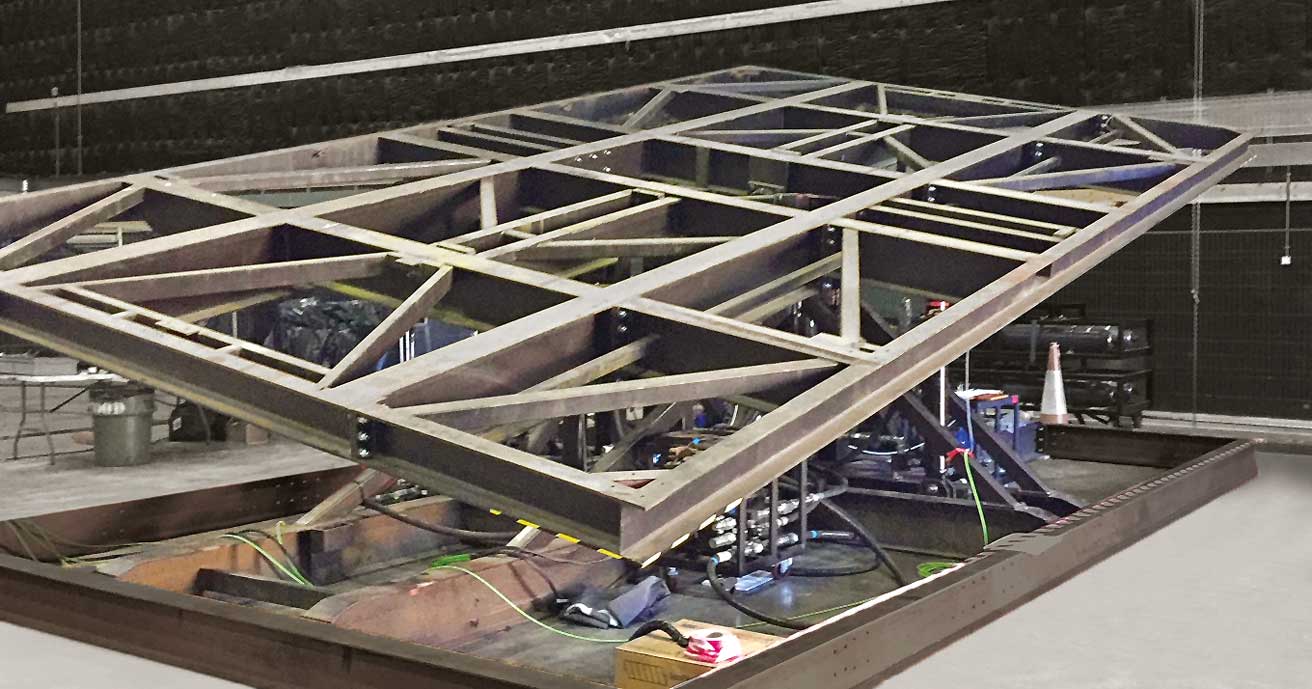

In a rescue scene, a fully occupied boat had to be tossed back and forth as authentically as possible in high waves. There were three hydraulic movement axes in the form of the Trio Motion Technology and a fourth for the rotational movement, which the integrated draw-wire encoder made possible. "It allowed us to route through the visual effects in the Maya special effects platform and have the motion go anywhere to be in the camera's view," explains Andy Ryan.

Capacitive sensors for measurements under temperature fluctuations

Capacitive sensors for measurements under temperature fluctuations

The SGH10 position sensor provided another advantage in the following dynamic applications: Several cylinders were to be moved synchronously on the platform. In addition to the position, the draw-wire encoder also determines the Speed. This allows the cylinders to extend at the same speed while running parallel.

Safe movements in the midnight sky

The film crew also had an integrated SGH10 draw-wire encoder on board for the special effects in the film "Midnight Sky". Main character Sully had to sit on a chair in the communication room of the spaceship and drive sideways and vertically to her various control buttons. Under the chair was a hydraulic cylinder with the integrated SGH10 Measurement Technology, the height and travel speed particular. This ensured the actress' safety and the movement appeared smooth.

The pull-wire sensor integrated in the hydraulic cylinder also proved to be the best solution here, because the space under the chair on the floor was very limited. "Constrained space is the rule in our projects," confirms Andy Ryan, "so that we often fall back on the compact draw-wire encoders from Siko. In addition, our team appreciates the Versatility of measurements, since both linear and rotational movements can be detected. This enables a wide range of applications.”

Externally mounted position sensor

In addition to the position sensors integrated in the cylinder, Siko also offers externally attachable draw-wire encoder. Absolute Moco also uses these in certain applications. The SG10 and SG20 sensors are very compact external draw-wire encoders with a maximum measuring length of 2000 mm. In the case of an existing basic construction, for example, these draw-wire encoders can also be integrated later. This significantly reduces the design effort.

In addition to the position sensors integrated in the cylinder, Siko also offers externally attachable draw-wire encoder. Absolute Moco also uses these in certain applications. The SG10 and SG20 sensors are very compact external draw-wire encoders with a maximum measuring length of 2000 mm. In the case of an existing basic construction, for example, these draw-wire encoders can also be integrated later. This significantly reduces the design effort.

For Andy Ryan, it's important that the sensors work on more complicated hydraulic ramps interchangeable are: “If there is a mechanical problem and the sensor is likely to fail, it is much easier to replace an external pull-wire encoder than it is to disassemble the entire ramp to replace an in-cylinder sensor. The time saving is crucial here.” In these cases, the team prefers the external position sensors.

Simple connection of the draw-wire encoder

Absolute Moco does not manufacture the hydraulic cylinders itself, but has them manufactured by a subcontractor according to their own specifications and designs. Siko draw-wire encoders are also integrated. The top priority is the security of all functionalities. Both the integrated and the external pull-wire encoders can be very simply integrate and put into operation. Andy Ryan finds: “We have a separate motion control system with different interfaces and were very satisfied that the draw-wire encoder was also immediately operational with our own connection. Just connect and start. The manuals and accompanying documents from Siko are also very helpful.”

Ultrasonic sensors for distance, distance and level

Ultrasonic sensors for distance, distance and level

Absolute Moco is currently working on a film production for Marvel Studios. "This time we try Pushing the limits with our hydraulic effects' Andy Ryan insists. "Of course, the draw-wire encoders from Siko are also used again."

Siko exhibits at the Automatica 2022.

What is a cable encoder?

A cable encoder is a displacement sensor system that is used for the precise position detection of objects. This is done using a cable that is integrated on a cable drum in the sensor housing. The cable is rolled up and down on the drum by a pre-tensioned mainspring while the position of the measurement object changes. The cable drum is connected to an encoder (digital) or potentiometer (manual). If the linear movement of the spool changes to a rotary movement when the rope is being rolled up and down, the measuring unit changes accordingly to a rotary encoder or potentiometer. Both then convert the mechanical change into electrical signals and transmit them to the appropriate devices for evaluation and further processing.

You might also be interested in...

Siko GmbH | 60 years of 'out of the box' thinkers

Position display with IO-Link monitors format adjustment

Positioning drive | For precise format adjustment