Material mix for new properties

High-performance compounds, natural fiber compounds, glass fiber reinforced plastics, thermoplastic composites and fiber composites

Image: Vienna University of Technology

Material mix for new properties

High-performance compounds, natural fiber compounds, glass fiber reinforced plastics, thermoplastic composites and fiber composites

Image: Vienna University of Technology

We present you the latest innovations on the topic Composites for use in industry, of high performancecompounds, Natural fiber compounds using glass fiber reinforced plastics, thermoplastic Composite materials up to Fiber composites. Composite materials or composites are materials that are composed of two materials and thus offer new properties.

Contents

CompositesAlso Composite materials called, use the best of several worlds for optimal product properties such as special rigidity or strength. Composite materials also sometimes consist of several connected components or layers of for example Plastic or aluminum, which form the so-called composite material. The materials involved are connected material or form-fitting or a combination of both. Composite materials in a composite offer better properties than the individual material could.

In the following paragraph you will find Composites or composites and peripheral materials or processes from specialists such as Covesto, Rampf, or Centroplast. In the section below, we present the results of research in this area.

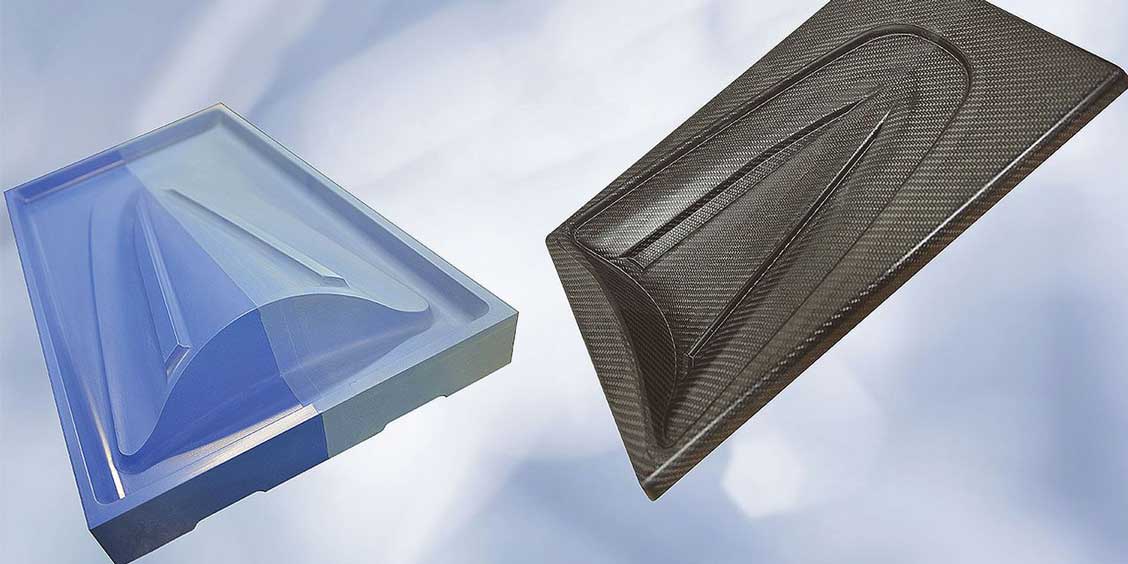

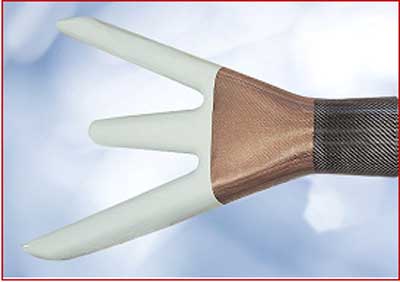

Rampf develops tailor-made solutions for the entire production process from prototype construction to the construction of models, molds and Tools through to production. Are new to the portfolio Liquid resin Systems for structure and interior composite materials. With the epoxy resin Block and liquid materials can be first-class Forms and Model Implement products made of epoxy resin.

With "Raku Tool" the Rampf Group offers model and mold making materials and complete solutions based on them for carbon fiber and glass fiber composite materials. The company covers the demand with three competence centers worldwide.

With "Raku Tool" the Rampf Group offers model and mold making materials and complete solutions based on them for carbon fiber and glass fiber composite materials. The company covers the demand with three competence centers worldwide.

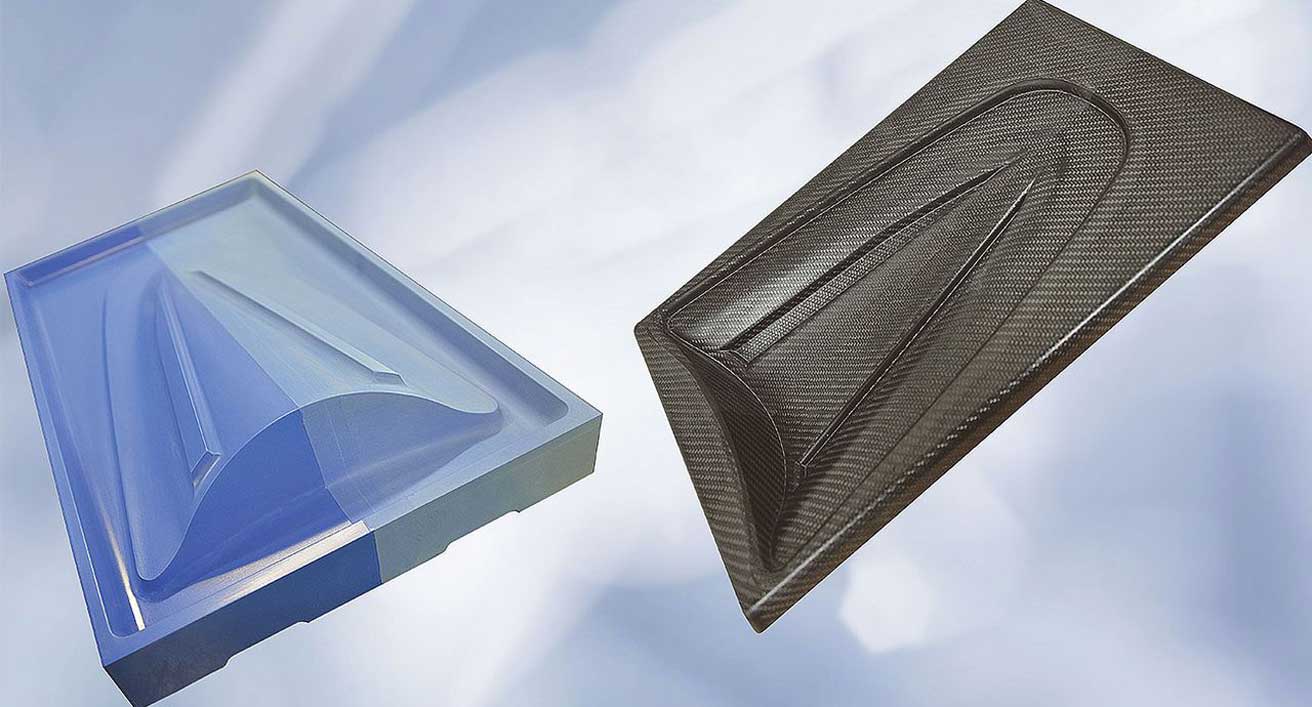

Rampf Tooling Solutions presents the new epoxy block material “Raku Tool WB-0890”, specially developed for the composite industry. The semi-finished product has an extremely fine surface structure, which significantly reduces both the finishing effort and the sealant consumption.

Rampf Tooling Solutions presents the new epoxy block material “Raku Tool WB-0890”, specially developed for the composite industry. The semi-finished product has an extremely fine surface structure, which significantly reduces both the finishing effort and the sealant consumption.

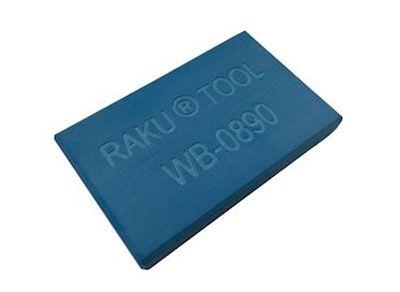

Rampf presents a structural resin for the fairing in the aircraft main landing gear and a cyanate ester infusion system for the Composite Aviation manufacturing. The new cladding replaces the previous aluminum shell, thus avoiding problems caused by natural frequencies. The low-viscosity infusion system offers first-class mechanical properties. Both innovations meet the high demands on the Fire protection.

Rampf presents a structural resin for the fairing in the aircraft main landing gear and a cyanate ester infusion system for the Composite Aviation manufacturing. The new cladding replaces the previous aluminum shell, thus avoiding problems caused by natural frequencies. The low-viscosity infusion system offers first-class mechanical properties. Both innovations meet the high demands on the Fire protection.