for mechanical and plant engineering

High-precision cutting tools and non-cutting tools for machines as well as clamping technology for jig and mold construction

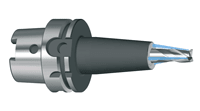

Image: Dormer Pramet

for mechanical and plant engineering

High-precision cutting tools and non-cutting tools for machines as well as clamping technology for jig and mold construction

Image: Dormer Pramet

Here you will find new products from the Tooling for construction and production with tools for machine and plant construction for the production of industrial goods, especially for machine tools as well clamping means or entire manual workstations for modern production with the highest precision. The precision tools presented here can be found in the Metalworking for the Automotive industry, electrical industry, Aircraft construction and much more. Commitment.

The precision tool industry is one of the largest specialist areas in mechanical engineering. You manufacture quality products with high-precision cutting tools and non-cutting tools. grips, Workholding as assemblies for the jig and Mold making and entire devices are required by the equipment designer for efficient toolmaking.

Find out about precision tools, fixtures and clamping technology for your Engineering Construction.

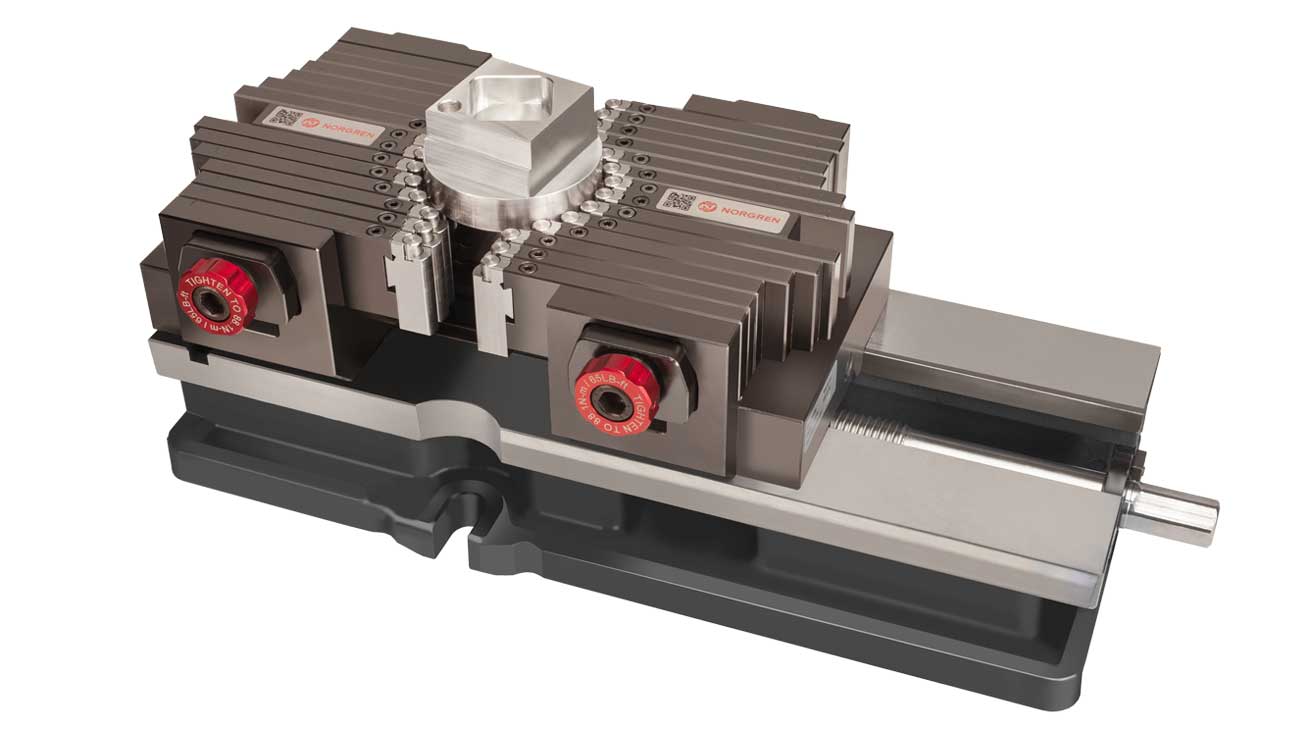

The one presented here Workholding is used to fix and hold a workpiece in devices, machine tools or machining centers. clamping jaw, collet, Quick release, chipboard, Mandrel & Co. must work safely, precisely and reliably when milling, turning, grinding and other processing of workpieces. Below you will find New developments different manufacturers:

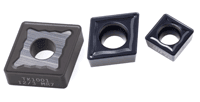

The carbide grades TK1001 and TK2001 from Seco Tools are convincing in demanding casting processes and, thanks to the patented "Duratomic" coating, achieve a long service life. After the introduction of 14 Duratomic grades, the TK1001 and TK2001 are a new generation of cutting materials for turning cast materials on the market.

The carbide grades TK1001 and TK2001 from Seco Tools are convincing in demanding casting processes and, thanks to the patented "Duratomic" coating, achieve a long service life. After the introduction of 14 Duratomic grades, the TK1001 and TK2001 are a new generation of cutting materials for turning cast materials on the market.

The Heinrich Kipp Werk presents further developments in the Workholding: Two new quick and power clamps with a black surface prevent reflections in the optical metrology. With the Multiple clamping system different workpieces can be clamped. The flexible 5-axis vice tilt flexx designed. Of the Mandrel with eccentric lever works without tools. You can find these and other innovations below:

Sleep Pramet presents new ones drill: one Solid Carbide Drills for aluminum, one Replaceable head drill , and a Spot drill for precise centering. The program is suitable for civil engineering and mechanical engineering. The focus is on large diameter holes. The range of solid carbide heads for steel, stainless steel and cast iron is combined with a robust HSS tool body.

Sleep Pramet presents new ones drill: one Solid Carbide Drills for aluminum, one Replaceable head drill , and a Spot drill for precise centering. The program is suitable for civil engineering and mechanical engineering. The focus is on large diameter holes. The range of solid carbide heads for steel, stainless steel and cast iron is combined with a robust HSS tool body.

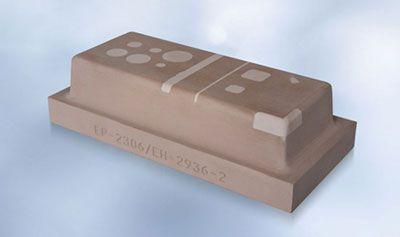

Easy to use, quick to harden: Rampf Tooling Solutions presents four new “Raku Tool” epoxy repair fillers for block materials. They are easy to process, cure faster at room temperature and have very low shrinkage.

Easy to use, quick to harden: Rampf Tooling Solutions presents four new “Raku Tool” epoxy repair fillers for block materials. They are easy to process, cure faster at room temperature and have very low shrinkage.

There are only a few all-electric ones so far Tool changer on the market, mostly pneumatic ones are used here. The electric ones already on offer only cover the area of small mechatronic ones grab away. Since the trend here too is 'exchange Pneumatics due to Electrics' does not stop at further development Gimatic electrical Tool changer included in the program. this as well hand-operated novelties and a case study from the 3D concrete printing can be found below:

Nils Knepper, Product Manager modular PLC / software, Mitsubishi Electric Europe BV, Ratingen, is presenting a manual workstation that can be used to implement zero-error assembly based on the manufacturer's products.

Multi-bladed reamers are the tool of choice when high cutting rates and short machining times are required. Due to the limitations of conventional manufacturing processes, it has not been possible with steel base bodies to distribute the coolant specifically to all effective points of the tool. Thanks to additive manufacturing, Mapal has succeeded in reshaping the coolant supply and the coolant outlet shape and optimally adjusting it to friction machining.

Multi-bladed reamers are the tool of choice when high cutting rates and short machining times are required. Due to the limitations of conventional manufacturing processes, it has not been possible with steel base bodies to distribute the coolant specifically to all effective points of the tool. Thanks to additive manufacturing, Mapal has succeeded in reshaping the coolant supply and the coolant outlet shape and optimally adjusting it to friction machining.

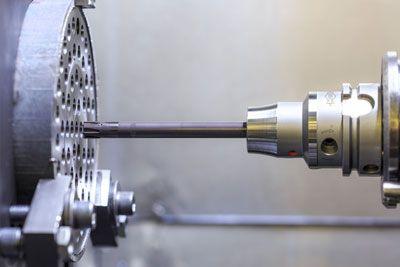

There are different chuck for processing workpieces on a machine, including power chucks, jaw chucks or eccentric chucks. They all have in common that they either die Tools such as drills or milling cutters. Or they clamp the ones to be machined as a so-called lathe chuck workpieces on the machine. We present new developments like that here lathe chuck with optimized power transmission, which Röhm will present at the AMB 2022.

Precise machining and extremely tight tolerances are particularly important in medical technology, for example in the manufacture of bone screws or other small medical parts and microcomponents. The fast and reliable production of threads is a particular challenge here. For this reason, Sandvik Coromant has now developed inserts and holders for the "Coromill 325" for use on Swiss-type lathes, which can significantly optimize production processes.

Precise machining and extremely tight tolerances are particularly important in medical technology, for example in the manufacture of bone screws or other small medical parts and microcomponents. The fast and reliable production of threads is a particular challenge here. For this reason, Sandvik Coromant has now developed inserts and holders for the "Coromill 325" for use on Swiss-type lathes, which can significantly optimize production processes.

Elco offers a wide range of high-performance tools for mold making and light machining. The company develops tools and solutions for processing panels and profiles made of plastics and composites especially for applications in the aerospace industry and in lightweight construction. It also produces a variety of shrink fit chucks.

Elco offers a wide range of high-performance tools for mold making and light machining. The company develops tools and solutions for processing panels and profiles made of plastics and composites especially for applications in the aerospace industry and in lightweight construction. It also produces a variety of shrink fit chucks.

Installation, milling or drilling often have to be done quickly. So it's good if the workpieces can be easily fixed - and even better if you don't even need a tool. Ruwi has designed innovative clamping modules that make exactly that possible. The eccentric clamping modules are produced by the Heinrich Kipp factory, where they are now part of the standard range.

Installation, milling or drilling often have to be done quickly. So it's good if the workpieces can be easily fixed - and even better if you don't even need a tool. Ruwi has designed innovative clamping modules that make exactly that possible. The eccentric clamping modules are produced by the Heinrich Kipp factory, where they are now part of the standard range.