Industrial Ethernet | Profinet, Powerlink & Co.

- Details

- Hits: 31573

The Industrial Ethernet is increasingly establishing itself as an extension of the standard Ethernet in Industry 4.0 environments. During the establishment of field buses sinks, the market for grows Profinet, Ethernet/IP, Ethercat and all other industrial networks. However, the increasing IIoT applications are demanding more and more. OPC UA and TSN should solve that and the proprietary protocol problem. Here you can find out how Industrial Ethernet is developing further.

Contents

- Industrial Ethernet – state of development and trends

- Powerlink, Profinet & Co. today

- Further growth for Industrial Ethernet

- Record values for Profinet and IO-Link 2023

- Profinet, IO-Link, Profisafe and Profibus development 2019

- Industrial Ethernet is overtaking fieldbuses

- Powerlink as the only IEEE61158 standard

- Learning from Profibus for Profinet

- Smooth transition from Profibus to Profinet

- Simply from the Profibus to the Profinet with an adapter

- Basics of Industrial Ethernet

Industrial Ethernet – trends and developments

Current Industrial Ethernet solutions are designed to function reliably in demanding industrial environments, where noise, temperature fluctuations and electromagnetic interference require ever more robust designs. But the most important feature today is this real-time capability, which is required for applications such as motion control. The integration of Industrial Internet of Things (IIoT) devices is also important today because Sensors and devices are networked on a large scale so that they can collect data for analysis, process optimization and Maintenance provide. The technology is also scalable and can support small to large networks. It thus provides a flexible infrastructure for the machines and systems in production.

Powerlink, Profinet & Co. today

The relentless increase in data rates results in a need for more data transfer and bandwidth. This requires even higher Ethernet speeds, especially in data-intensive applications. Cyber threats must be defended against with advanced encryption and authentication mechanisms. There is also a trend towards computing at the edge of the network (Edge Computing) instead of in central data centers. This reduces latency and allows decisions to be made more quickly. Some Industrial Ethernet solutions are now integrating AI Algorithmsto enable anomaly detection, predictive maintenance, and other advanced capabilities. The lines between information technology (IT) and operational technology (OT) are blurring as companies seek a unified Ethernet network infrastructure that integrates both office and production systems.

Further growth for Industrial Ethernet

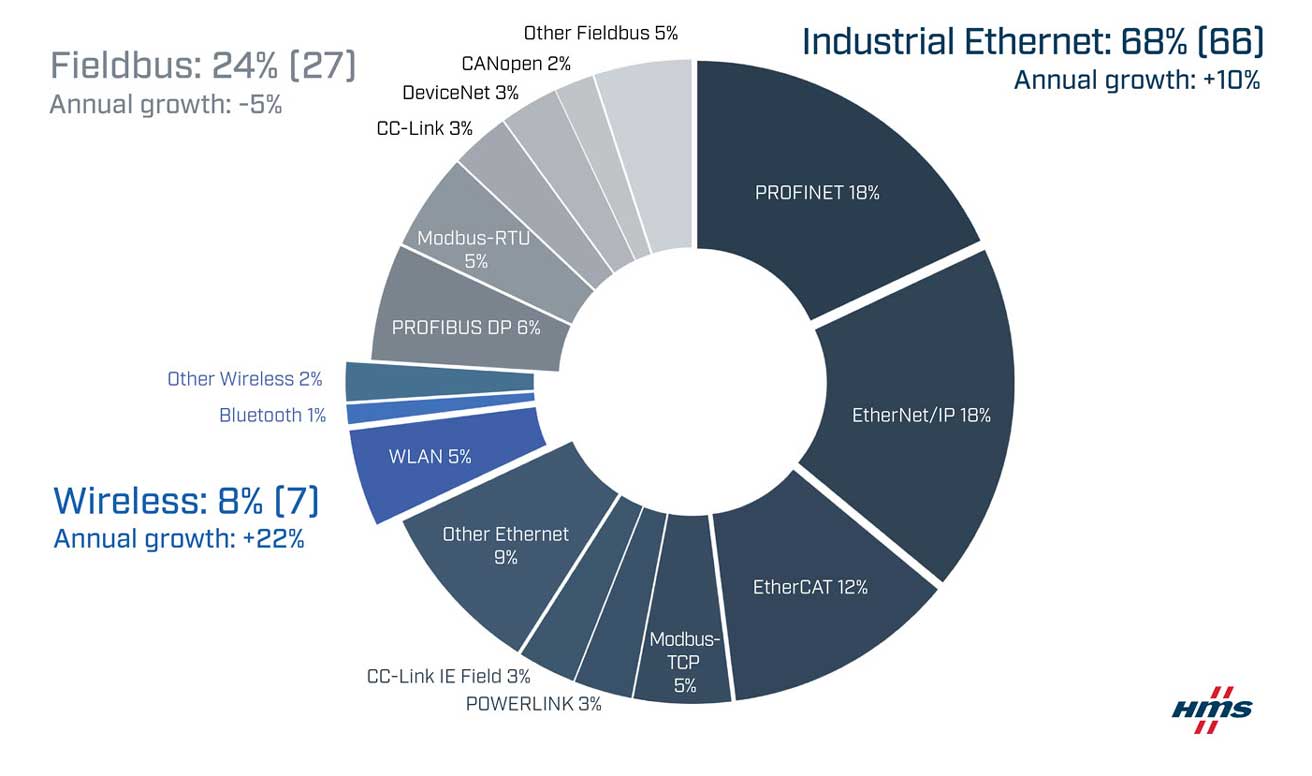

05.06.2023 | HMS Networks conducts annual research into the industrial networking market (pictured above) to identify trends in the newly integrated nodes in factory automation. According to the 2023 report, this market is expected to expand by 7%. Industrial Ethernet continues to grow and now represents 68% of all recently deployed nodes, up from 66% last year. The use of fieldbuses drops to 24% (from 27% in the previous year). At the same time, the market share of wireless solutions is increasing and is now at 8%, up from 7% last year. Profinet and Ethernet/IP each dominate the network hit list with 18%, while EtherCAT contributes 12%.

head to head race

The head-to-head race between Profinet and Ethernet/IP continues as both lead the 2023 network rankings with 18% market share each. Incidentally, last year's growth for fieldbuses was only temporary, as new fieldbus installations are expected to fall by 2023% in 5. Despite the decline in new fieldbus nodes, it can be assumed that fieldbuses will continue to be used for several years simply because they are tried and tested and reliable.

The wireless networks grow with you + 22% rapidly in 2023 because more and more wireless industrial network solutions are moving into factory automation. Typical applications are replacement of Cable, machine access via radio and the integration of mobile devices in industrial networks.

Regional differences

In Europe and the Middle East, Ethernet/IP, Profinet and Ethercat are at the top, closely followed by Profibus and Modbus-TCP. In the US, Ethernet/IP dominates the market while EtherCAT is rapidly gaining popularity. In Asia, Profinet has established itself as the market leader, closely followed by Ethernet/IP. CC-Link/CC-Link IE Field, Ethercat, Profibus and Modbus (RTU/TCP) are also widely used here.

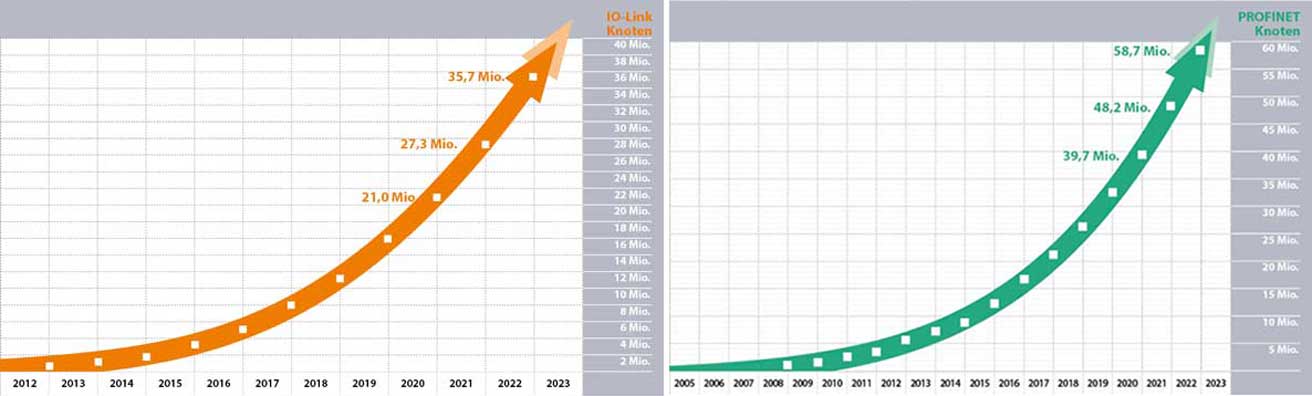

Record values for Profinet and IO-Link 2023

01.05.2023/2022/XNUMX | The notarial annual evaluation XNUMX for installed products with Profibus & Profinet Interfaces is pleasing, especially with Profinet and IO-Link. In addition, the growth of Profisafe has increased significantly compared to 2021. In 2022, Profinet set a new record with 10,5 million nodes. That was 2 million more than in 2021 and thus an increase of 23,5%. To date, a total of 58,7 million Profinet devices have been installed.

IO-Link recorded one increase of 8,4 million. devices in 2022 and thus 2,1 million more than in the previous year. The growth is 33%, bringing the total number to 35,7M nodes. In 2022, Profisafe achieved its best annual value to date with 2,8 million nodes, a total of 21,7 million devices are in use. In 2022, with 1,5 million devices, Profibus reached the value of the previous year. In process automation, the value remained stable at 0,8 million. This leads to a total installation of 67,4 million Profibus devices, of which 15,4 million are integrated in process engineering systems.

Profinet, IO-Link, Profisafe and Profibus development 2019

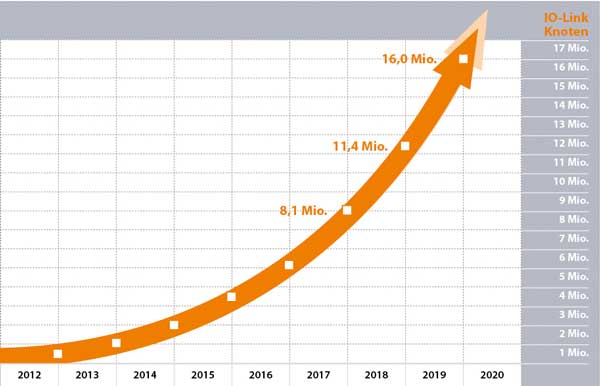

07.05.2020 | The technologies of Profibus + Profinet International (PI) are still very well received in the market after more than 30 years since their development. The biggest increase over the year was seen in 2019 IO-Link with 40%, Profinet achieved 25% and there are also encouraging figures for Profisafe and Profibus.

07.05.2020 | The technologies of Profibus + Profinet International (PI) are still very well received in the market after more than 30 years since their development. The biggest increase over the year was seen in 2019 IO-Link with 40%, Profinet achieved 25% and there are also encouraging figures for Profisafe and Profibus.

In the working groups at Profinet and IO-Link, the experts have further developed the communication technologies and provided important additions for their use in Industry 4.0-compliant production. An example of this are the two Companion Specifications, in which OPC UA compatible information models for IO-Link and Profinet are described.

"For us, the latest count of installed nodes is the best proof that we have made a number of correct decisions in the past regarding the development of our technologies," commented Karsten Schneider, CEO of the Profibus user organization and Chairman of PI the latest count of installed nodes.

With 40% increased just like a year earlier IO-Link in 2019. This shows that IO-Link will establish itself in the market in the long term. The number of installed IO-Link devices is now more than 16 million.

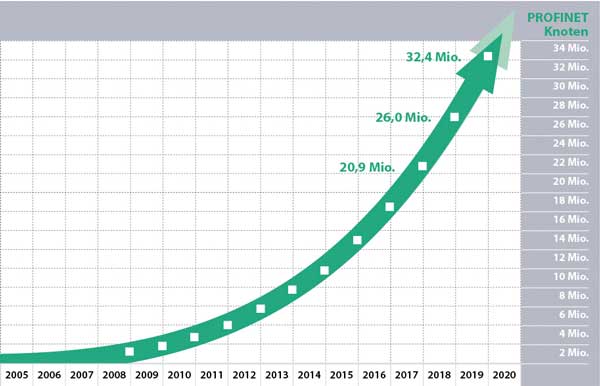

Record value for Profinet installations

With 6,4 million devices installed Profinet achieved the highest annual value so far. This corresponds to a growth of 25% and results in a number of 32,4 million nodes.

With 6,4 million devices installed Profinet achieved the highest annual value so far. This corresponds to a growth of 25% and results in a number of 32,4 million nodes.

“Profinet stands for reliable and future-proof communication technology that already very well fulfills the requirements from the Industry 4.0 perspective. To ensure that this will continue in the long term, our experts, increasingly in cooperation with experts from other organizations, are constantly working on firmly anchoring Profinet as an enabler for digitalization in production, ”says Karsten Schneider.

This is also impressively demonstrated by the results of other market studies. For example, IHS Markit found that Profinet with 29% Most widely used Ethernet-based system worldwide at a hunt.

PROFIsafe achieved 2,5 million installed nodes in 2019, surpassing 2 million for two consecutive years. The total number of installed Profisafe nodes is almost 14 million. Last but not least reported Profibus despite its long market presence, it is still an impressive number with 1,9 million new nodes. At the end of 2019, more than 62 million Profibus devices were installed in industrial plants worldwide. Of this, more than 13 million were used in process engineering systems.

"Motivated by the success of the market, our members worldwide are heavily involved in technological advancement and in numerous marketing projects," says Karsten Schneider. "In this context, it is to be hoped that the virus-related obstacles are short-lived and that people in business and in the private sphere can soon return to normality."

Smooth transition from Profibus to Profinet

05.07.2019 | A few years ago, Profinet made the leap into the age of Ethernet-based communication. The Indu-Sol video shows how the transition from Profibus to Profinet works smoothly and how stable network operation can be guaranteed from the first telegram.

Industrial Ethernet is overtaking fieldbuses

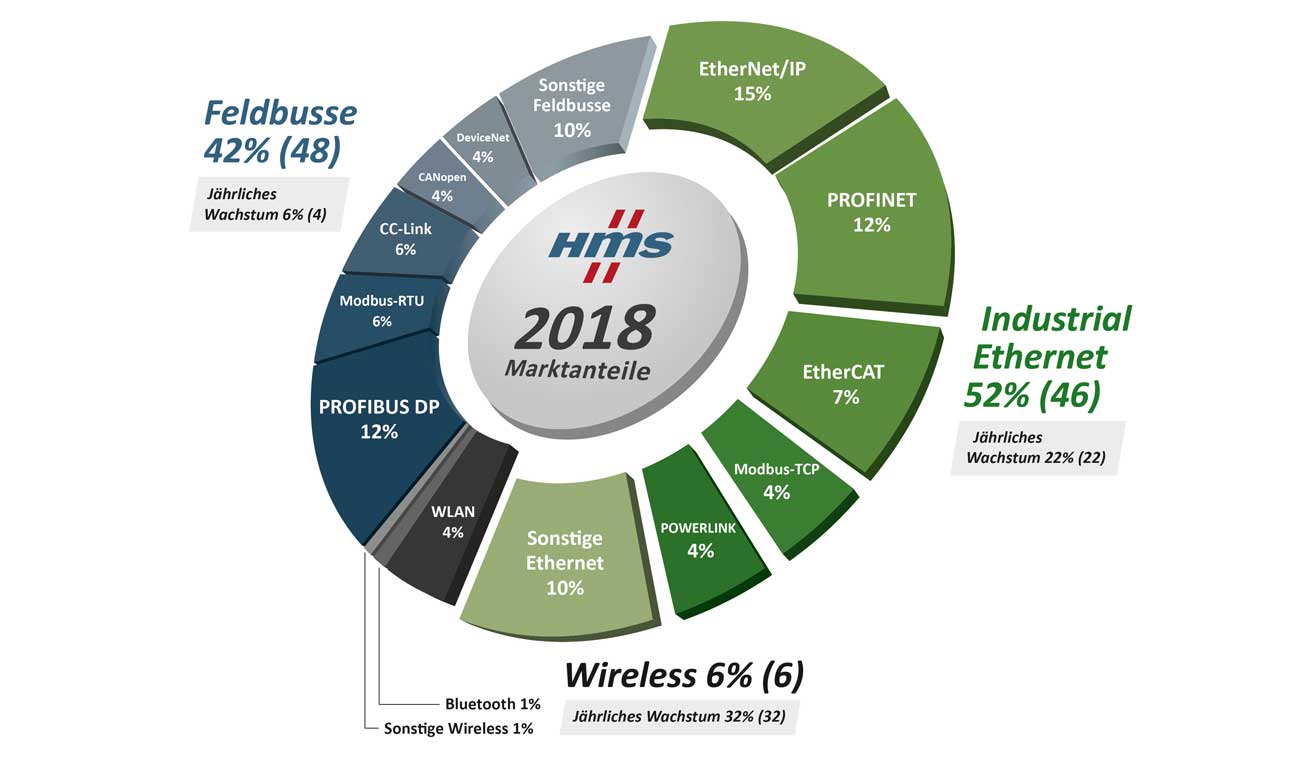

06.04.2018 | With regard to newly installed nodes in the factory Automation Industrial Ethernet has the traditional ones fieldbusse outdated. This is the key finding of our annual study of industrial network market share.

We annually evaluate the industrial networking market, focusing on newly installed nodes within factory automation. As an independent provider of products and services for industrial communication and the Internet of Things, we have in-depth insight into the industrial network market. We see some trends for industrial communication in 2018, but also look back at the development of industrial network market shares over the last 5 years.

Industrial Ethernet - growth through IIoT

For several years, Industrial Ethernet networks have grown faster than traditional fieldbuses and have now overtaken the latter. With a growth rate of 22% Industrial Ethernet now has a market share of 52% worldwide, compared to 46% in the previous year. Ethernet/IP has become the most widely used network with a 15% market share, followed by Profinet, Ethercat, Modbus-TCP and Ethernet Powerlink.

For several years, Industrial Ethernet networks have grown faster than traditional fieldbuses and have now overtaken the latter. With a growth rate of 22% Industrial Ethernet now has a market share of 52% worldwide, compared to 46% in the previous year. Ethernet/IP has become the most widely used network with a 15% market share, followed by Profinet, Ethercat, Modbus-TCP and Ethernet Powerlink.

We followed developments closely and the transition to Industrial Ethernet was foreseeable, but only now has it overtaken fieldbuses in terms of the number of newly installed nodes. The main drivers for Industrial Ethernet are the need for higher Performance, the integration of factory installations and IT/IoT (Industrial Internet of Things) systems and the IoT in general.

Fieldbus still widespread - decline expected

Thanks to a strong industry and concerns about Cybersecurity fieldbuses are still growing slightly. Nevertheless: Although fieldbuses have increased slightly with a growth rate of 6% (previous year 4%), it can be assumed that the number of fieldbus installations will steadily decrease over the next few years. The dominant fieldbus is still Profibus with a 12% global market share, followed by Modbus-RTU and CC-Link with 6% each.

radio technologies are growing by 32% (previous year also 32%) and make up 6% (previous year also 6%) of the overall market. Within wireless, WLAN is the most widely used technology, followed by Bluetooth. Wireless is increasingly being used by machine builders and system integrators to implement innovative automation architectures. Users can reduce cabling and implement new solutions for connectivity and control, including Bring Your Own Device (BYOD) – using tablets or smartphones.

Regional differences

In Europe and the Middle East are Profinet and Ethernet/IP leading. Profibus is also still widespread there. Other popular networks are Ethercat, Modbus-TCP and Ethernet Powerlink. The US market is dominated by CIP networks, with a clear shift towards Ethernet/IP. No network is the market leader in Asia, but Profinet, Ethernet/IP, Profibus, Ethercat, Modbus and CC-Link are widespread. The Ethernet version CC-Link IE Field is also gaining in importance.

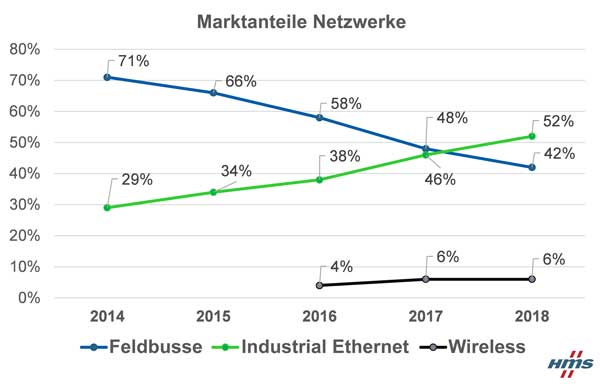

Review of 5 years of industrial network growth

A special feature of this year's study is that HMS can look back on 5 years of steady growth in industrial networks. We conclude that in 2017, Industrial Ethernet finally overtook fieldbuses in terms of market share. It is interesting to note that Industrial Ethernet has, and is, surpassing traditional fieldbuses 52% of the market makes, here Ethernet/IP has established itself as the leading network.

A special feature of this year's study is that HMS can look back on 5 years of steady growth in industrial networks. We conclude that in 2017, Industrial Ethernet finally overtook fieldbuses in terms of market share. It is interesting to note that Industrial Ethernet has, and is, surpassing traditional fieldbuses 52% of the market makes, here Ethernet/IP has established itself as the leading network.

Despite this, our study also confirms that the networking market remains fragmented - users continue to ask for connectivity to a variety of different networks, depending on the application. Looking to the future, it is becoming clear that industrial devices will be powered by the IoT and Industry 4.0 increasingly networked with each other. From our point of view, we are well positioned to grow with these trends. As our claim 'Connecting Devices' says, that's what HMS is all about.

database

The study includes estimates from HMS for 2018 based on newly installed node in 2017 in the field of factory automation. A node is defined as a machine or device connected to an industrial network. The figures are a consolidated view of HMS based on its own sales statistics, peer industry insights and overall market perception.

Powerlink as the only IEEE61158 standard

22.06.2017/XNUMX/XNUMX | That EPSG Powerlink protocol was adopted by the IEEE as the international standard IEEE61158. It is the only Industrial Ethernet that has achieved this status. The IEEE standards too TSN and Powerlink are therefore central components for industrial real-time communication from the point of view of the IEEE.

22.06.2017/XNUMX/XNUMX | That EPSG Powerlink protocol was adopted by the IEEE as the international standard IEEE61158. It is the only Industrial Ethernet that has achieved this status. The IEEE standards too TSN and Powerlink are therefore central components for industrial real-time communication from the point of view of the IEEE.

The IEEE, the Institute of Electrical and Electronics Engineers, is the world's largest professional association of engineers in the fields of electrical engineering and computer science. One of their most famous achievements is the IEEE802.3 standard, also known as Ethernet. The IEEE working group Industrial real-time communication has been working on the definition of an Industrial Ethernet standard for the past two years. In March 2017, the working group finally adopted Powerlink as the sole IEEE standard with 97% approval.

"Until now, industrial real-time communication has been a blank spot at the IEEE," said dr Victor Huang, responsible for standardization at the IEEE Industrial Electronics Society (IES) after the vote. "Powerlink combines high performance with unrestricted openness, so it ideally complements the previous IEEE communication standards." "The adoption of Powerlink as an IEEE standard is an important step towards standardizing industrial automation technologies at field level," added Prof. Aleksander Malinowski, IEEE Industrial Electronics Society (IES) Senior Adcom Member.

Learning from Profibus for Profinet

29.02.2012/XNUMX/XNUMX | Profinet is becoming more and more established as the communication standard for Industrial Ethernet applications. Users can also benefit from the experience gained over the years in using the Profibus with Profinet. This includes e.g. B. the realization that an externally visible network function should not be used as a measure for the assessment of network quality according to the motto "It works...". The contribution of Indu-Sol shows which quality criteria have to be met and how this can be implemented.

The advantages of Profinet are obvious: All network structures such as ring, star, line or network can be implemented through to reduced susceptibility to interference Point to point wiring realize. In addition, Profinet is convincing as an open, manufacturer-neutral, internationally standardized bus standard and can point to constantly increasing user acceptance. Finally, Profinet complements the PC-based very well Automation services and enables easy vertical integration from the field level to the enterprise level. However, network communication experts warn against approaching the topic too naively. Karl-Heinz Richter, Managing Director for Marketing & Sales Indu-Sol GmbH, rather advises to learn from the experiences with Profibus.

Ethernet switches | The data driver in the network

Ethernet switches | The data driver in the network

While at Profibus 90% of the problems that have occurred in bus communication can be traced back to physical causes (caused by LAN cables, lines, connectors), in Profinet the perspective is increasingly directed towards the evaluation of logical communication contexts due to the possibility of transmission of different protocols within a network. If you want to know the actual quality of your communication and not just judge it by system function or the number of failures, you need concrete values.

The network previously interpreted correctly

If you compare Profinet with Profibus the amount of data to be transmitted and the transmission speed seem almost unlimited. In contrast to Profibus, however, the communication load is not constant, which makes it difficult to predict reliable communication. The necessary load reserves must therefore be planned in advance and the network structure must be well thought out.

If you compare Profinet with Profibus the amount of data to be transmitted and the transmission speed seem almost unlimited. In contrast to Profibus, however, the communication load is not constant, which makes it difficult to predict reliable communication. The necessary load reserves must therefore be planned in advance and the network structure must be well thought out.

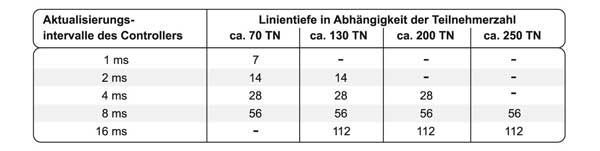

In the same way that heavy loads are not sent out on country roads or at peak traffic times if possible, it is important in Profinet that the communication channels designed according to the load. For example, a surveillance camera should be connected as directly as possible to the visualization system or, to stay with the picture, not be routed through various towns and villages. Another keyword in planning is line depth (cascading of I/O devices). It is important to clarify in advance whether the line depth is suitable for the respective application if a certain update rate is to be observed. Line depth, applied to the image of road traffic, means how many traffic lights or traffic light crossings (switches) have to be passed on the way to the destination.

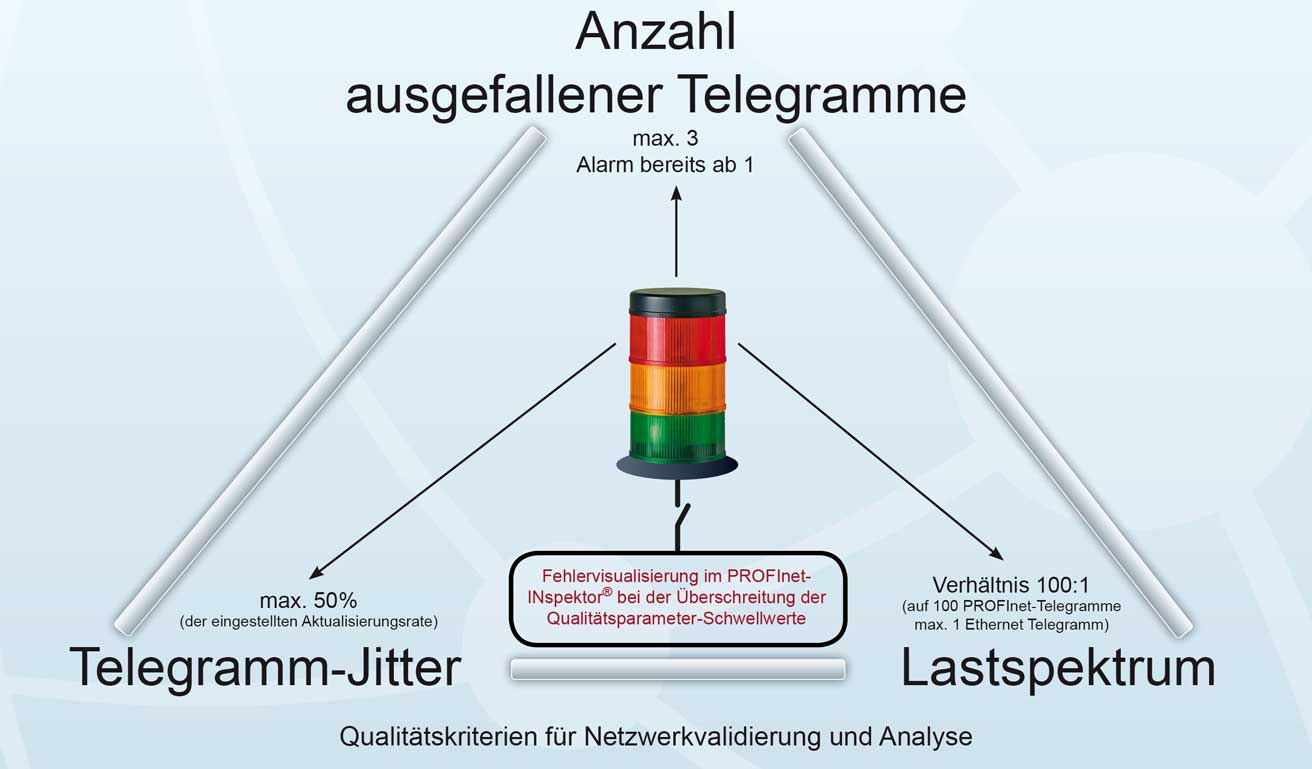

Three measurable network state variables

In the measurement practice, the network experts from Indu-Sol have opted for Profinet three measurable network status variables crystallized out, which could well establish themselves as generally valid quality criteria in Profinet communication: the telegram jitter, the number of failed telegrams and the load spectrum as in the relationship between Profinet and TCP/IP. Networks can be reliably planned and optimally designed from the outset if these quality criteria and their limit values and relationships to one another are taken into account.

Regarding the difference between theory and practice, Richter explains: "Two general causes usually lead to the fact that Theory and practice not match. Firstly, the implementation often does not follow the plan exactly. Here, measurements can help to control planning data. Secondly, with complex systems it is often not possible in the planning phase to take all eventualities into account, and the executor is deliberately given certain freedom in the network design (installation). Here, measurement in real operation can help to optimize settings or the communication paths.” If you want to bring theory and practice together, this is only possible with reliable measurement results, e.g. B. with network monitoring under production conditions over a longer period of e.g. 14 working days. If you don't want to judge the quality of the communication by the "status LED" of the controller or by the number of failures, you need one thing above all: clear and comprehensible quality criteria.

Quality criteria for the Profinet communication

In the practice of network experts, three network status variables have emerged for Profinet, which could well become established as generally applicable quality criteria in Profinet communication: the telegram jitter, the number of failed telegrams and the load spectrum (e.g. the ratio of Profinet to TCP/IP) (Figure 2).

In the practice of network experts, three network status variables have emerged for Profinet, which could well become established as generally applicable quality criteria in Profinet communication: the telegram jitter, the number of failed telegrams and the load spectrum (e.g. the ratio of Profinet to TCP/IP) (Figure 2).

The jitter is a measure of the deviation from the refresh rate. Richter explains: “We can compare the jitter with the arrival times of public buses, for example. If we expect a bus every hour and it sometimes comes too early and sometimes too late, we can speak of a time deviation from the actually expected timetable. With Profinet, we set the 'arrival times' via the update intervals. If a time deviates by more than 50 percent, the question of 'why' is a must. From the outside, however, one would not notice this fact of an early indication of a problem.”

The detection of failed telegrams as the second criterion is similar to that with Profibus Retry limit to see. The important difference, however, is that with Profibus the telegrams are repeated and with Profinet up to three missing telegram packets are tolerated without it being externally visible to the operator.

The third Profinet criterion, the general bus load or traffic, includes the sum of all cyclic and acyclic data traffic. Richter states: “Here too, a comparison from road traffic can help us to understand 'bus load' or 'traffic'. With the Profibus, only one car of the type “car” ever drives from A to B or vice versa. In addition to car traffic, with Profinet we also have the option of allowing trucks or motorbikes to drive on the same road. In terms of the evaluation, it is now important to know the percentage ratio of the respective participants to each other in the traffic load. A guide value for the load spectrum is a ratio of 100:1, i.e. a maximum of one Ethernet telegram should be transmitted for every 100 Profinet telegrams."

Furthermore, in a well thought-out network planning, it is important to consider in advance which loads can occur when and how they can be sensibly distributed to achieve good overall utilization of the network. Here, too, Richter mentions an empirical value: “With a maximum Bus load of 20 percent network communication can definitely be ensured without unexpected communication failures. To put it figuratively: When the roads in Schmölln are 20 percent full, as a driver you can be sure that there will always be free travel and a green wave, no matter where you come from or drive to with your car.”

Calibrate lines yesterday

In order to ensure communication reliability with the Profibus from the outset, the first step is usually to check the physical line quality. This is also important, as with the Profibus there are often up to 30 participants on one line. In the Profinet, where there are 30 lines for 30 participants, this procedure is not only time-consuming and expensive, but also harbors the risk that the installation will be actively interfered with by tapping and cutting, which could result in new sources of error. Richter on this: "Even a discussion with experts did not result in a clear majority for 'for or against' in relation to a line test in Profinet."

In order to ensure communication reliability with the Profibus from the outset, the first step is usually to check the physical line quality. This is also important, as with the Profibus there are often up to 30 participants on one line. In the Profinet, where there are 30 lines for 30 participants, this procedure is not only time-consuming and expensive, but also harbors the risk that the installation will be actively interfered with by tapping and cutting, which could result in new sources of error. Richter on this: "Even a discussion with experts did not result in a clear majority for 'for or against' in relation to a line test in Profinet."

From Indu-Sol's experience to date, a properly performed Online test do without the line test as an acceptance criterion in the Profinet. If all three of the quality criteria mentioned are met in the online test, you can also assume that the line quality is right. Conversely, defects in lines are already visible based on deviations in the quality parameters. By using a diagnostic tool such as the Profinet Inspector, which uses these three criteria to assess the communication quality, there is no need for time-consuming and expensive offline cable tests in the sense of acceptance.

Long term on the safe side

In addition, the 'online check' with the Profinet Inspector the advantage that all abnormalities are recorded using the web-based visualization and clearly displayed with a time stamp and real values. This makes it easier to analyze which problem was caused by what. In this way, networks can not only be planned sensibly from the outset, but reliable communication can also be ensured in the long term. For this purpose, it is advisable to use the inspector as a 'long-term ECG' of the system during the entire system running time. All changes, especially surprising ones, caused by acyclically occurring amounts of data can be detected at any time and communication problems can be avoided.

Easy to change from Profibus to Profinet via adapter

08.12.2014 | Profinet is increasingly becoming the standard in factory and process automation. But today not all field devices have the necessary interface. With his Netlink Proxy offers Hilscher However, with its migration technology it is a solution with which existing Profibus field devices can also be easily integrated into the Profinet world.

08.12.2014 | Profinet is increasingly becoming the standard in factory and process automation. But today not all field devices have the necessary interface. With his Netlink Proxy offers Hilscher However, with its migration technology it is a solution with which existing Profibus field devices can also be easily integrated into the Profinet world.

Basics of Industrial Ethernet

What does Industrial Ethernet mean?

Industrial Ethernet refers to the application of the Ethernet standard in industrial automation and production. While Ethernet was originally developed for office and home networks, the industrial version has been modified and adapted for the special requirements of industry.

What is the difference between Fieldbus and Industrial Ethernet?

The following four distinguishing features are the most important:

- robustness: Industrial Ethernet is designed for use in harsh industrial environments. The hardware and Ethernet cables are often more resistant to physical influences such as temperature, vibration or electromagnetic interference.

- real-time communication: Now required in many industrial processes, the Industrial Ethernet protocol offers mechanisms for deterministic data transmission. These ensure that data is delivered within a predetermined time.

- Scalability: From small machine networks to large production plants, scalable IE solutions can grow with the requirements of the company.

- Safety: IE systems are often equipped with advanced security features to protect networks from cyber attacks.

What is the difference between Ethernet and Profinet?

Ethernet was originally developed for the home network and general data traffic. It is the dominant technology for LAN engineering and is used in a variety of environments. Both Ethernet and Profinet are based on the same basic Ethernet technology. Profinet was specially optimized for the requirements of industrial automation and offers advantages in industrial environments such as real-time communication, extended diagnostic functions and the possibility of integration into existing systems.

What is an Ethernet protocol?

The Ethernet protocol is a standardized communications protocol that governs data transmission on local area networks (LANs). To explain: It defines how data packets are created, transmitted and received in a network. The Ethernet protocol uses a specific data packet structure. The so-called Ethernet frames contain, among other things, the destination and source MAC addresses, user data and error checking information. Ethernet can detect collisions of data packets and control devices accordingly. The transfer rate has gone from 10Mbps (original standard) to speeds of 100Mbps (Fast Ethernet), 1Gbps (Gigabit Ethernet), 10Gbps, 40Gbps and even 100Gbps and also increased.

Which Ethernet protocols are there?

Here are some of the common Industrial Ethernet protocols:

- Profinet (PROFessional NETwork) is the extension of the Profibus standard, developed by the Profibus & Profinet International (PI) organization. Profinet offers real-time Ethernet communication and is mainly used in automation and manufacturing environments.

- Ethercat (Ethernet for Control Automation Technology) is an open, real-time Ethernet communication system developed by Beckhoff. It is characterized by short cycle times and precise synchronization.

- Ethernet / IP (Ethernet Industrial Protocol) was developed by the ODVA (Open Devicenet Vendor Association). Ethernet/IP is based on the Common Industrial Protocol (CIP) and allows industrial devices to interact over an Ethernet network.

- Modbus/TCP is an Ethernet adaptation of the well-known Modbus protocol. It enables communication between automation components and is particularly widespread in process automation.

- Powerlink was originally developed by B&R. The real-time protocol ensures deterministic data transmission.

- Sercos III (SErial Real-time COmmunication System) is the third generation of the Sercos interface designed for high-speed communication between industrial devices.

- CC Link IE (Industrial Ethernet) is a protocol widely used in Asia, developed by the CC-Link Partner Association. It is a

High-speed field network with reduced wiring for manufacturing applications. CC-Link IE is preferred by Mitsubishi Electric.

You might also be interested in...

Artificial Intelligence | trends and developments

Predictive maintenance for robotics, machines and systems

Mitsubishi Electric | Automating the World

Cobot | Discover collaborative robots as a new employee

Intelligent CNC control for machine tools