Rigid coupling | Torsionally rigid shell coupling

- Details

- Hits: 10980

An rigid coupling or Shell coupling offers advantages such as backlash-free shaft connection or high torque transmission. Find out how rigid couplings ensure precise power transmission and fail-safe connections in your drive solution. Optimize your systems with proven solutions known for their robustness and easy installation.

Contents

- Rigid coupling for different shaft diameters

- Rigid coupling for heavy duty applications

- Clam couplings for transmitting high torques

- FAQ

Rigid coupling for different shaft diameters

October 16.10.2019, XNUMX | Torqmax step bore series rigid couplings Orbit Drive Technology Thanks to their stepped bores, they enable the backlash-free connection of shafts with different diameters. For a low mass moment of inertia, the Couplings Made of aluminum, additionally anodized to protect against corrosion and partly also available in stainless steel.

There are two options: GMC in standard length and the compact ZMC for tight installation spaces. A wide range of bore diameters is available for these rigid couplings in every coupling size.

Slip clutch + overload clutch limit torques

Slip clutch + overload clutch limit torques

Here, the user can choose the matched coupling with graduated bore diameters to match the shafts to be connected. For example, the size GMC43 / ZMC43 offers a range of nine different bore diameters from 10 to 22 mm, which can be freely combined with the shaft.

In addition to the Standard version as a rigid coupling in a slotted, one-piece version offers this shaft coupling An optional version split on one or both sides for independent clamping of the two stepped shafts. This results in the possibility of being able to radially remove a shaft that is frequently to be dismantled or replaced without having to loosen the other shaft connection with the rigid coupling.

The shaft coupling Compact version ZMC in four sizes is now also available as a stainless steel version with selected hole combinations.

Rigid coupling for heavy duty applications

25.01.2017/XNUMX/XNUMX | Orbit Antriebstechnik offers with the series Torqmax Heavy Duty rigid couplings for heavy duty applications with high torque performance. The couplings are available for shaft diameters from 55 mm to 120 mm. They are designed in two parts and can therefore be mounted radially. There are versions for the backlash-free connection of shafts with different diameters stepped bores.

The multi-plate clutch and its industrial applications

The multi-plate clutch and its industrial applications

For an additional form fit, the Torqmax Heavy Duty with groove executed. The heavy duty version is made of steel and is also blued. Stainless steel versions are available as an option.

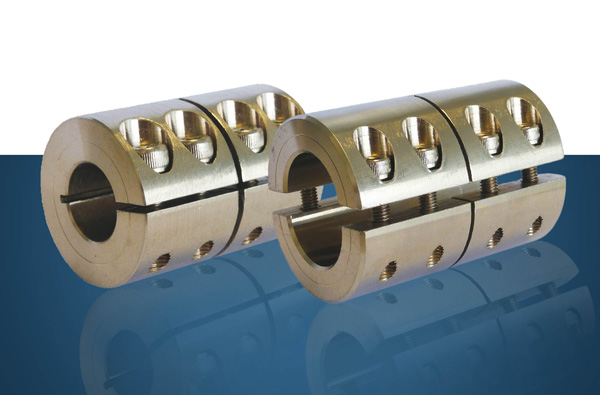

Clam couplings for transmitting high torques

25.06.2012 | KBK Antriebstechnik is expanding its delivery program to include one- and two-piece shell couplings for transmitting high torques. Both versions are available either in burnished steel or stainless steel with bore diameters from 5 to 50 mm. Especially the stainless steel versions are suitable for use in the food, pharmaceutical and chemical industries.

25.06.2012 | KBK Antriebstechnik is expanding its delivery program to include one- and two-piece shell couplings for transmitting high torques. Both versions are available either in burnished steel or stainless steel with bore diameters from 5 to 50 mm. Especially the stainless steel versions are suitable for use in the food, pharmaceutical and chemical industries.

Rigid couplings like the one-piece one KBST and the two-part one KBST G are used wherever several shaft pieces of the same diameter have to be connected via a frictional connection to form a long drive shaft - such as in the wood industry. But designers also use non-switchable clutches when connecting turbine and dynamo shafts in power plants.

One-piece shell coupling

The one-piece version of the KBKShell coupling covers the wave completely. It is pushed onto the shaft and tightened radially with four screws. This results in a high torsional force without damaging the shaft due to micro-friction. The two-part half-shell design can also be mounted radially on fixed shafts. It can be easily dismantled and therefore enables quick and easy maintenance of the parts to be connected. It is not necessary to remove other components. Regardless of whether it is a one-piece or two-piece version – the shell couplings are installed very quickly.

metal bellows coupling | Innovations, applications and special features

metal bellows coupling | Innovations, applications and special features

Tight manufacturing tolerances guarantee extensive contact between the shaft and coupling in both variants, thus maximizing the torque transmission capacity. The largest force-transmittable torque is 2250 Nm. The wear-free and maintenance-free shell couplings can be used for both directions of rotation. Keyway keyways can also be implemented.

FAQ

What is a rigid coupling?

A rigid coupling is a drive element that connects two shaft ends firmly and immovably. It belongs to the group of non-switchable clutches and transmits torque in a torsionally rigid, backlash-free and consistent manner. The torsionally rigid shell coupling does not compensate for shaft misalignments.

Where are rigid couplings used?

Rigid couplings are used where a exact shaft alignment is possible and no shaft shifts or displacements may occur. Possible applications of the design include: B. machine tools, pumps or compressors.

What rigid couplings are there?

There are different types of rigid couplings such as disc couplings, shell couplings, flange couplings and beam couplings. They are used depending on the requirements of the application.

Which non-switchable clutches are there?

Non-switchable clutches that permanently establish a connection between drive and output elements include:

- Rigid Couplings for direct connection without flexibility, such as disc, shell and flange couplings.

- elastic Couplings transmit torque with a certain degree of flexibility, including e.g. B. Elastomeric or spring couplings.

- Torsional rigidity, flexible couplings such as disk or diaphragm couplings can compensate for axial, radial or angular shaft misalignment.

- Universal joint- And drive shaftsCouplings for angular connections between shafts with high misalignment.

Source: This article is based on information from the following companies: KBK Antriebstechnik, Orbit Antriebstechnik.

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.