for machine safety

with safety brakes as well as hydraulic, electromagnetic or spring-operated brakes

Image: Mayr drive technology

for machine safety

with safety brakes as well as hydraulic, electromagnetic or spring-operated brakes

Image: Mayr drive technology

Discover the world of Industrial brake, an essential component in modern drive technology. From disc brakes to specialized braking systems, leading manufacturers offer reliable solutions for a variety of applications. Find out how the various... Types of brakes contribute to the safety and efficiency of machines and systems and how braking energy can be saved.

Where masses are accelerated, they must also be brought to a standstill. That's what the brake does. It also ensures the necessary safety in the event of a power failure, machine downtime or emergency stop. The following three Types of brakes There are therefore: stop brake, control brake and holding brake. A large group of industrial brakes is the safety brake. It is spring-operated and has the task of protecting people and ensuring machine safety.

Within the Personal developments When it comes to industrial brakes, the focus today is on efficiency, reliability and integration into intelligent systems. The current state of development also focuses on improving braking performance under extreme conditions and reducing maintenance costs.

A growing one trend is the use of brakes combined with sensor technology and advanced data analysis. This is intended to monitor performance and prevent premature failures, keywords condition monitoring or predictive maintenance. In addition, more environmentally friendly brake materials are becoming increasingly important to improve sustainability. Overall, innovations in materials science, electronics and software are driving the development of more efficient and intelligent braking solutions in the industry. Below you will find new developments Industrial brakes 2023.

There are different types of brakes in the industry. But what exactly is a stop brake, control brake, holding brake, safety brake, disc brake, rotation brake, electromagnetic brake, magnetic brake, permanent magnet brake, profile rail brake, drum brake, floating caliper brake, thruster brake, band brake, double brake, hydraulic brake, pneumatic brake, spring-loaded brake, spring-loaded brake, caliper brake, caliper disc brake, Sliding caliper brake, spring brake, electric brake, elevator brake, azimuth brake, pitch brake, yaw brake... These and certainly more names can be found on the Internet on the subject Industrial brake. We present the most important ones to you below:

Discover the Electromagnetic brake, their functionality and areas of application. As precise Spring pressure brake or efficient Permanent magnet brake They are essential for control and safety in automated and manual drive systems. Learn how these innovative braking systems improve performance and ensure reliable operation.

Within the disc brake you first think of the bicycle. However, this type of brake is also used in industrial drive systems. These robust brakes can be precisely controlled and are very reliable. Whether as Thruster brake in lifting devices, electromagnetic for the machine tool, as a fixed caliper brake for holding or as a floating caliper brake in the function of a service brake: There are many applications for the type of brake invented by Frederick W. Lanchester.

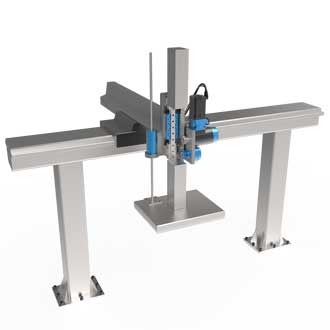

The Smart Brake Module is used for the fully automatic stopping of loads on the rail track. It was designed for manually moved trolleys and transport platforms and ensures that the load and trolley are held safely and automatically if obstacles block the route or manual push is no longer possible.

Security does not tolerate compromises. This is particularly true for robotics. Robots are often capable of complex and unpredictable movements. In the case of lightweight robots, they sometimes collaborate with humans even without a protective space. With it robotic arms In the event of a power failure, after switching off the power or after an emergency stop, the robot brakes do not sink or crash uncontrollably servo axes reliable and secure in their position.

If the power is switched off, if it fails, or if there is an emergency stop in machines and systems, the safety brake prevents vertical and horizontal axes from falling freely. This is the only way to avoid accidents and protect people and machines. For applications in mechanical engineering, Medical Technology, food technology, elevators or stage technology, there are tips for installation, new developments and applications.

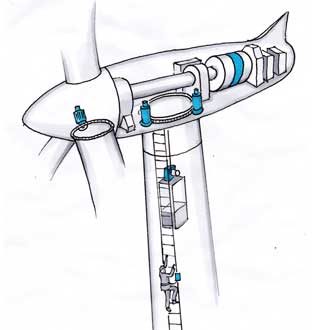

When brakes are used in elevators, they are referred to as elevator brakes, in wind turbines there are pitch or yaw brakes, and in automobiles, a modern brake-by-wire braking system ensures the safety of passengers. Special applications or industries require specialized brakes, which are often subject to certain certifications, for example in food or medical technology. Below we present some of them to you Industry brakes more precisely:

Whether in a handbike on the ice rink or as a mini brake in a space climber: when the user reports how well his supplier's brake works, this reference speaks volumes for the brake specialist. Some like that User stories We were happy to prepare it for you:

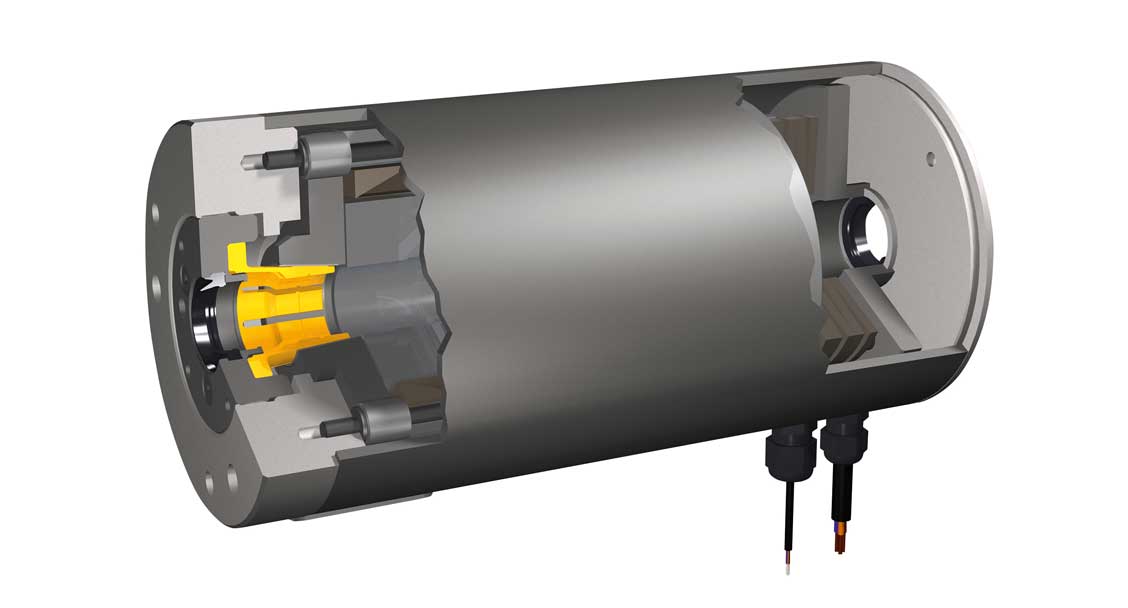

The Chr. Mayr GmbH from Mauerstetten, Germany, is a leading specialist in the field of drive technology. In addition to clutches, the family business offers a wide range of brakes. These include different types of safety brakes that are essential for precise control and safety in different industrial applications. The drive specialist's innovative brake technology is used in a variety of industries.

If the power is switched off, if it fails, or if there is an emergency stop in machines and systems, the safety brake prevents vertical and horizontal axes from falling freely. This is the only way to avoid accidents and protect people and machines. For applications in mechanical engineering, Medical Technology, food technology, Elevators or stage technology Mayr Antriebstechnik Safety brakes. Here you can find tips for installation, new developments and applications directly from the specialists:

The key points of tomorrow's machine maintenance are permanent inspection, needs-based maintenance - planned and appropriate to the workload, automated remote maintenance or error analysis across machines and plants. Mayr offers solution concepts in the area of brakes and clutches based on permanent inspection Condition monitoring and Predictive Maintenance. We present the new developments to you.

The Michael Koch GmbH from Ubstadt-Weiher in Germany is a trustworthy partner for the recuperation of braking energy and safe braking resistors for electric drives. Operating as an independent, privately owned company since 1997, the company focuses on the production of devices for active energy management and efficient braking resistors. Michael Koch GmbH offers tailor-made solutions from pilot projects to series production.

The active has three essential components Energy Management System Pxt by Michael Koch for the recuperation of braking energy: electronic devices, storage units and a small, intelligent module. The electronic devices move the energy highly dynamically and reliably either from the drive into the storage or vice versa, as in the event of a power interruption. The small module for current-based load peak reduction and capacity monitoring complete this Energy handling for drives.

Below you will find other manufacturers of brakes in industrial applications briefly and succinctly presented:

A holding brake is is specifically designed to maintain a stationary position and prevent machine parts or loads from moving unintentionally. It is often used in applications where a load or component needs to be secured in a fixed position when no driving force is applied. Such applications can be found, for example, in elevators, cranes or certain types of electric motors.

The choice of braking method depends on the application and the specific requirements of the engine. An electric motor is typically braked in one of the following ways:

An electromagnetic brake is used electromagnetic fieldto slow down or stop mechanical movement. When activated, current flows through a coil, creating a magnetic field and attracting a brake plate that acts on a rotating disc or drum. This friction creates a braking force that slows or stops movement. Known for their fast response time and precise control, electromagnetic brakes are often used in electric drive systems.

Sources: This article is based on information from the following companies: ACE, Kendrion Intorq, Mayr, Michael Koch, Ringspann.