Against the lack of chips: the performance center will be continued

- Details

- Hits: 4566

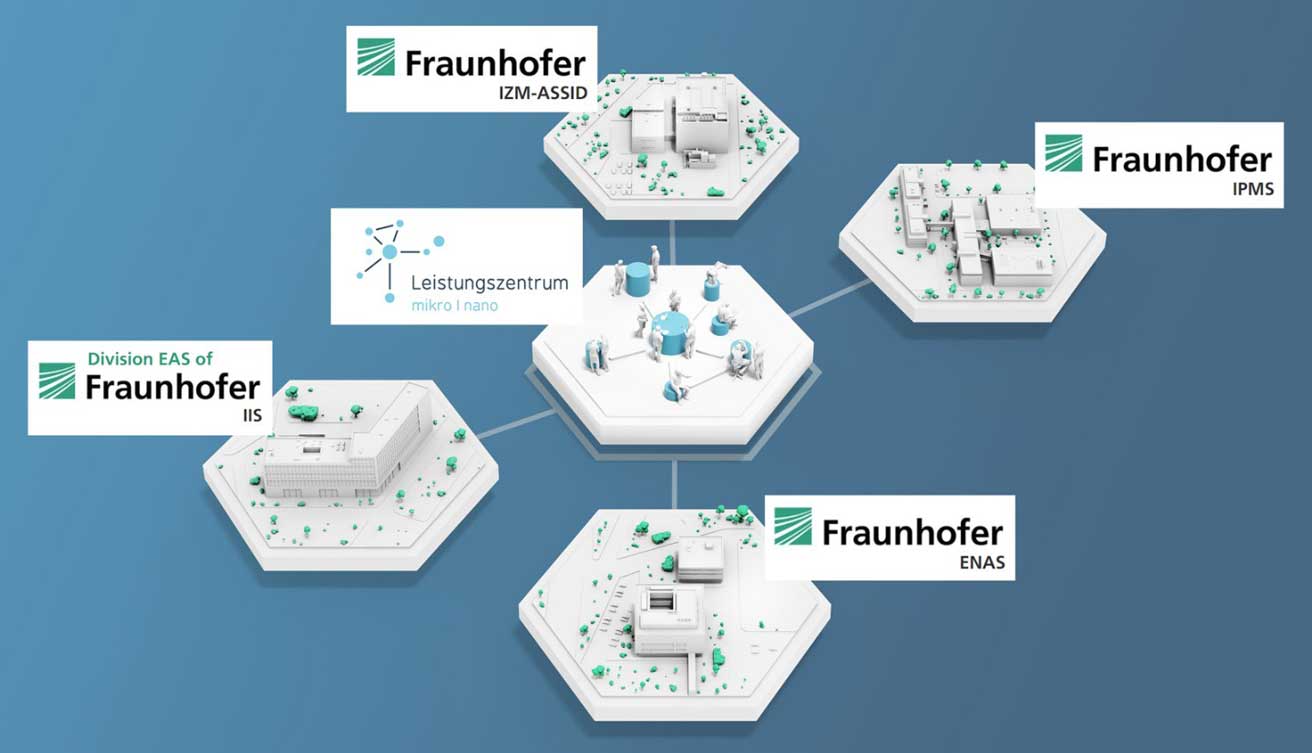

The economic consequences of unstable supply chains illustrate the importance of microelectronics, especially related to the current one chip shortage, Loud Fraunhofer technology sovereignty in research and development is required in order to be prepared for the future. New production facilities are also required in Europe. The High Performance Center for Functional Integration in Micro/Nanoelectronics faces this challenge. It bundles the competencies of several institutes.

Contents

Chip shortages destabilize supply chains

08.04.2022 | Especially the Auto industry such as BMW, Daimler or Volkswagen suffers from the lack of chips caused by the ones that have been around since 2020 Pandemic caused and since the war of aggression from Russia vs Ukraine was tightened even more. With the cooperation, the performance center creates a wide range of technologies in microelectronics and micromechanics. This is aimed both at the big players in microelectronics and at small and medium-sized enterprises (SMEs). By providing flexible technology platforms, they receive a low-threshold offer so that they can use high technology without having to develop the investment-intensive platforms themselves.

08.04.2022 | Especially the Auto industry such as BMW, Daimler or Volkswagen suffers from the lack of chips caused by the ones that have been around since 2020 Pandemic caused and since the war of aggression from Russia vs Ukraine was tightened even more. With the cooperation, the performance center creates a wide range of technologies in microelectronics and micromechanics. This is aimed both at the big players in microelectronics and at small and medium-sized enterprises (SMEs). By providing flexible technology platforms, they receive a low-threshold offer so that they can use high technology without having to develop the investment-intensive platforms themselves.

Following a decision by the board of directors of the Fraunhofer Society, the high-performance center micro / nano is now being extended in order to against the chip crisis to deliver. In the years 2022 to 2024, it will be funded with €1 million annually from Fraunhofer funds in its transfer activities and will be continuously evaluated. If there is a positive overall assessment at the end of the funding period, follow-up funding is provided for continuation for the next three-year period.

In the years 2016 to 2021, project funding for the high-performance center was also provided by the Free State of Saxony Institute-wide technology platforms developed. From now on, the focus is increasingly on the transfer to industry by offering research and development services using these platforms.

Bosch opens state-of-the-art semiconductor factory in Dresden

Bosch opens state-of-the-art semiconductor factory in Dresden

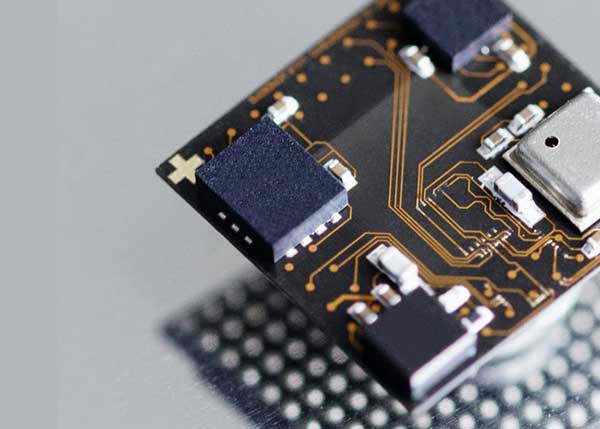

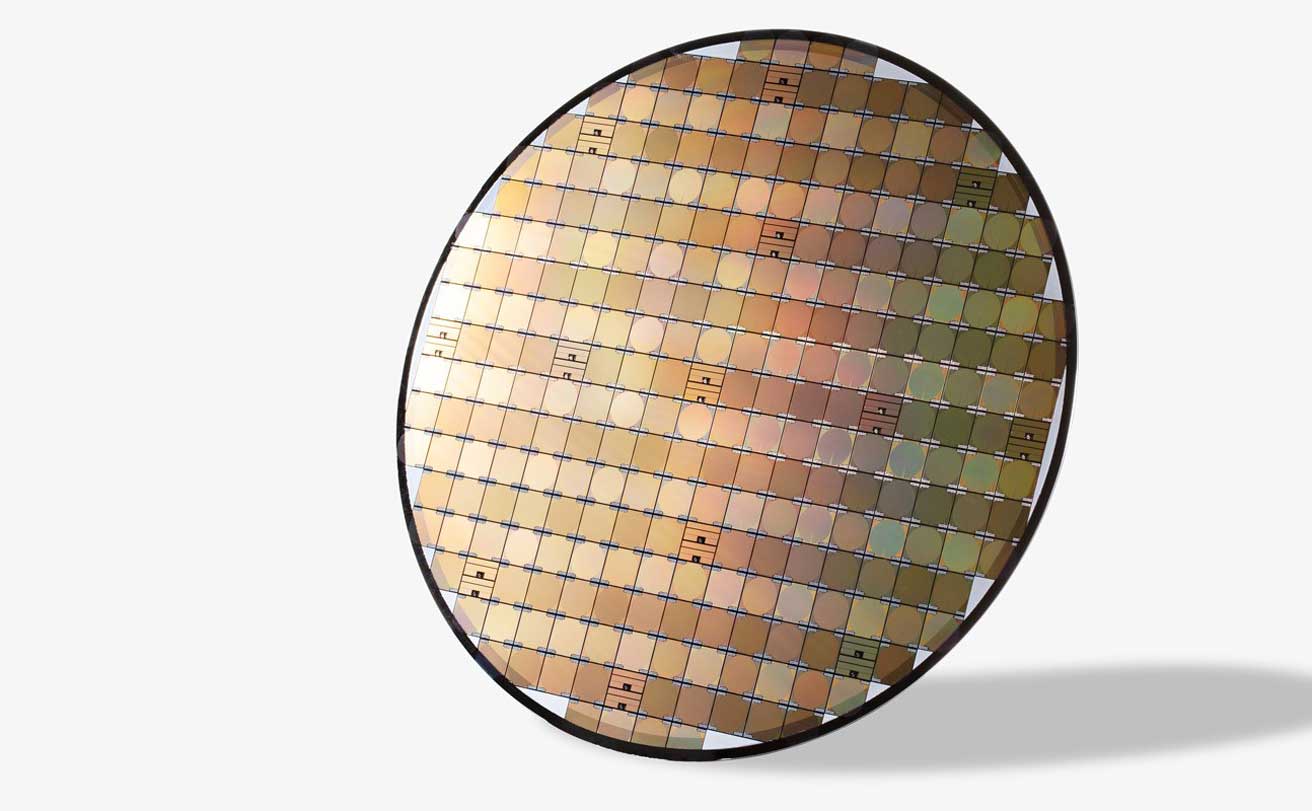

"The performance center micro / nano has established itself as a valuable partner of the industry and systematically transfers new research results to innovative product developments and applications," says Prof. Dr. Hubert Lakner, Coordinator of the High Performance Center of the Fraunhofer Institute for Photonic Microsystems IPMS. A thematic focus of the High Performance Center Micro / Nano is the area of integrated networked multi-sensor technology for the Industrial Internet of Things (IIoT), the development and use of micromechanical ultrasonic transducers (MUT) as well as the processing and wafer or semiconductor level packaging of 300 mm wafers . The offer includes classic contract research, the provision of demonstrators and prototypes as well as pilot production.

Research transfer on effective innovation ecosystems

performance centers organize the cooperation of university and non-university research with the economy. Universities, colleges, Fraunhofer Institutes and other non-university research institutions work together with companies and social actors on a specific topic at one location, so that innovations can be applied quickly.

The performance center micro / nano combines competencies of four Fraunhofer institutes IPMS, Enas, IIS / EAS and IZM Assid, supplemented by the relevant expertise from institutes at TU Chemnitz, TU Dresden and HTW Dresden. Project teams work together to develop solutions for the following research and development topics of high industrial relevance:

- New Materials for new functionalities

- Modular heterogeneous wafer systems

- Platform for Ultrasonic sensors

- Optical systems / integrated spectrometer with nanostructures

- sensors / Actuators in tools and machines.

In addition, the performance center offers the opportunity for application and customer-specific development as well as pilot production of components, circuits and System in Package (SiP) solutions for sensors and actuators. This is how cross-institute systems and demonstrators for sensors and actuators in Industry 4.0 applications and IIoT are created.

You might also be interested in...

Infrared camera optimizes Laser Powder Bed Fusion 3D printing

Artificial Intelligence | trends and developments

3D printer | Additive manufacturing of plastic parts

3D printer metal | Amazing Possibilities

Programming Robots | software and controls