Hygienic dosing systems for precise spreads

- Details

- Hits: 4817

technical articles

technical articles

The production of bread rolls in convenience FoodArea is a major logistical and, above all, production-related challenge. Automation plays an important role here. By using the Hygienic dispenser from Viscotec The precise application of chunky spreads or high-viscosity butter is possible.

A bottleneck and a very time-consuming step in the production process is the application of spreads such as butter or cream cheese as an ingredient of the sandwiches. This mostly manual operation can be automated in many applications to increase efficiency and production capacity.

The challenge with automation is in the detail: When metering in butter, it is important to dose the butter exactly in the hard-coat state. In addition, in preparations with cream cheese, the cheese mass is often mixed with pieces such as herbs, pieces of garlic or paprika, which complicate the automated order.

Dosing machine for sealing foam, adhesive + potting compound

Dosing machine for sealing foam, adhesive + potting compound

Because optics also play an important role in the food industry, it is important to build a bridge between functionality and visually attractive dosing results. What must always be in view: cycle times and costs. The Hygienic Dispensers master the challenges of automated dosing: spreads can be applied over a large area and precisely.

Proven continuous piston technology

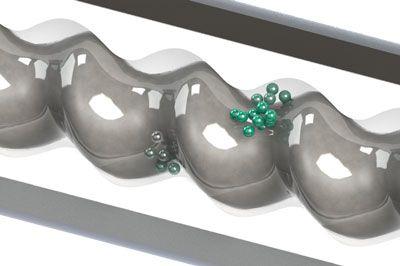

By using the proven endless piston technology, pastes can be applied in the best consistency as well as in a constant layer thickness. In addition, lumpy materials can be perfectly dosed. They are neither crushed nor ground in the dosing pumps. The appearance of the spreads is not impaired.

By using the proven endless piston technology, pastes can be applied in the best consistency as well as in a constant layer thickness. In addition, lumpy materials can be perfectly dosed. They are neither crushed nor ground in the dosing pumps. The appearance of the spreads is not impaired.

With its installed technology, ViscoTec guarantees a dosing accuracy of 99% (depending on the dosing material), which is often exceeded in practice. Another benefit of the continuous piston principle lies in the formation of delivery chambers whose volume remains absolutely constant during the course of the movement. This makes it possible to promote and fill solids laden media and even lumpy pastes. Even difficult, highly viscous liquids can be dosed reliably without pulsations, incorrect dosing or excessive stress on the material.

Flexible flat nozzles in different dimensions

Defining butter in the best possible consistency and applying it to baked goods is the goal. In perfect interaction of the Hygienic Dispenser with temperature-controlled, electrical heating components, this requirement is exactly implemented. This means that in large production lines, it is no longer necessary to do without butter as the basis for baked goods.

Through the use of flexible flat nozzles different widths of the spreads can be realized. The nozzles specially developed by the manufacturer save costly production time compared to a manual job. In order to be able to process different sizes and types of rolls, sandwiches or baked goods, the flat nozzles are available in different dimensions. They can be changed quickly and cleanly.

Hygienic dispensers equipped with flat nozzles can be easily integrated into production lines. In conjunction with automation solutions such as robotics, they also make simultaneous orders in multiple lanes possible.

Programmable retreat for clean work

With a minimum backward rotation of the rotor in the Hygienic Dispenser after dosing a perfect tearing of the medium is achieved, thus preventing any dripping. This means that the process is absolutely clean and the plant is not polluted.

Due to the precise and very precise dosage, the application thickness can be adjusted easily and flexibly. It no longer needs to be "overdosed" to ensure a consistent order. The high repeat accuracy ensures minimal rejects.

The hygienic design of the system and dispenser enable hygienic process design according to GMP. The Hygienic Dispenser can either be disassembled without tools within a few minutes and the individual components can be cleaned manually. Or it can be integrated as a CIP / SIP variant in an automatic cleaning or sterilization process.

By using the Hygienic Dispenser, the precise application of lumpy spreads or high-viscosity butter becomes possible. This enables automation of this step, which has hitherto mostly been carried out manually.

Above: Cutaway model of the Viscotec endless piston principle

You might also be interested in...

Artificial heart valve from the 3D printer

Microdosing of adhesive for the production of fiber optic cables

Optimized dispenser series and new rotor material for dosing technology

Filling and dosing of solids-laden liquids without sedimentation

Fast product changes when dosing different viscosities