Radar sensor in car headlights creates space in the vehicle

- Details

- Hits: 6896

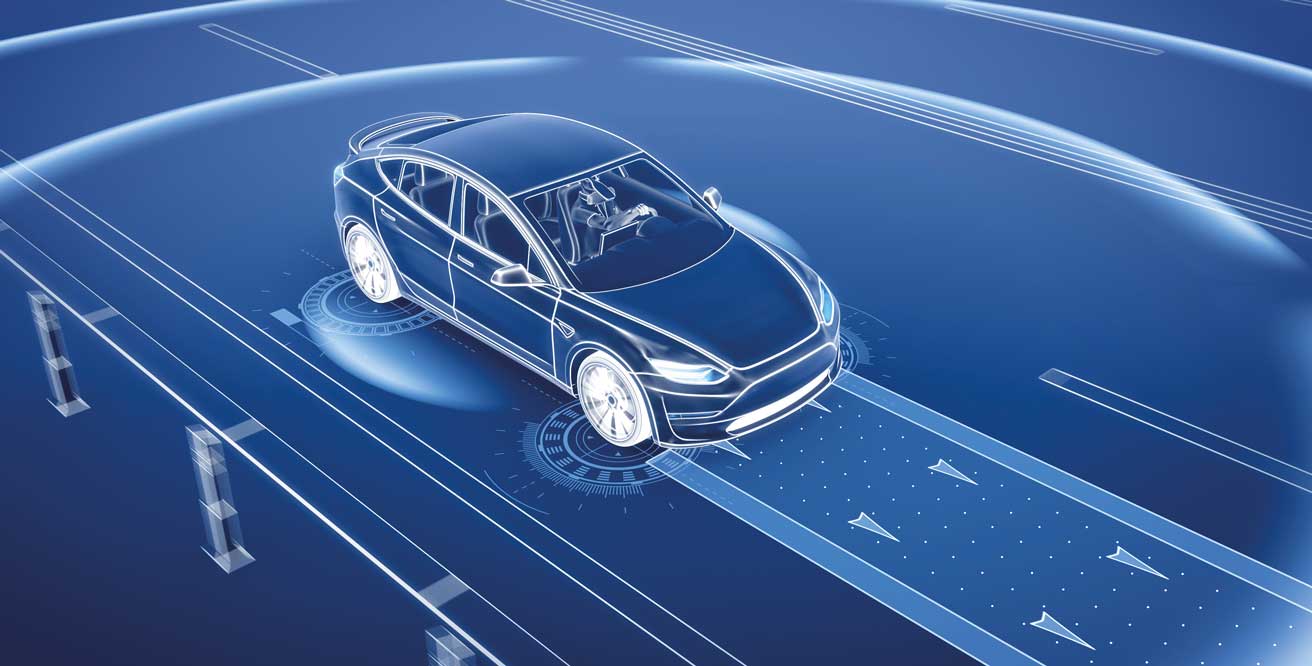

Modern Driving assistance systems use radar technology. There are many systems for adaptive speed control, support for changing lanes, avoiding collisions and recognizing pedestrians and cyclists. All pave the way to self-driving car. The Fraunhofer FEP now has one radar sensor developed in the Car headlights can be integrated.

Contents

Tree space for sensors is becoming scarce

The installation of an ever increasing number of Sensors limits the availability of exposed measuring points. There is hardly any more space available for installing sensors. The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP therefore developed these radar sensors. Such a radar sensor can be integrated into the headlight. The underlying project, which is funded by the Federal Ministry of Education and Research BMBF, is called Radar glass.

New type of silicone actuator for ergonomic controls

New type of silicone actuator for ergonomic controls

The integration of the radar sensors in the headlights of a vehicle protects them from snow, ice and rain. The outer vehicle shell is not affected. Designers of future generations of automobiles are no longer restricted by additional sensor structures on the vehicle.

Together with project partners, the researchers investigated which Thin film system radar waves can be controlled with little loss without restricting the lighting function of the headlamp. They developed a thin, transparent functional coating for an assembly mounted in the headlight. With it, the radar beams can be specifically shaped and directed.

Coating on the sensor directs radiation

The coating of the radar sensor can Beam propagation manipulate differently depending on the type of use. When detecting pedestrians, for example, the radar beams are directed to the side. The beam shape can be adjusted like an eye to the near or far range. To direct the propagation and shape of the radar beams, small areas of the coating have to be precisely structured using lasers. So they can act as antennas for the radar waves.

The coating of the radar sensor can Beam propagation manipulate differently depending on the type of use. When detecting pedestrians, for example, the radar beams are directed to the side. The beam shape can be adjusted like an eye to the near or far range. To direct the propagation and shape of the radar beams, small areas of the coating have to be precisely structured using lasers. So they can act as antennas for the radar waves.

“As part of the project, we developed a thin-film system that is almost transparent in the visible range and can also form high-frequency waves. The manufacturing process has been optimized to such an extent that the coating leaves the color of the light source unchanged and withstands temperature fluctuations between -30 ° and +120 ° C, ”explains dr Manuela Junghahnel, Project manager at Fraunhofer FEP.

A demonstrator was designed for the long range. With it, the radar can be bundled with a gain of 20 dBi (antenna gain) in a small beam width of 5 ° in the direction of travel. Obstacles up to 300 m away can be detected with the radar.

Institutes involved in Radarglass

In addition to Fraunhofer FEP, the Radarglass project also includes Institute for High Frequency Technology the RWTH Aachen and the Fraunhofer Institute for Laser Technology ILT involved. The experts from RWTH Aachen simulated the antenna layout and checked it with measurements in the 76 GHz to 81 GHz band. In this way, the suitability and performance of the radar reflector could be determined. The scientists at Fraunhofer ILT developed a high-precision laser ablation process for structuring the antennas on the coating.

3D printing process | manufacturing of the future

3D printing process | manufacturing of the future

Radar glass opens up many applications in the automotive and supplier industries. From the current development trend to autonomous vehicles A variety of impulses can be expected. In addition to licensing agreements, those responsible are seeking further collaborations with industry in order to achieve this radar sensorto be able to produce them in series.

You might also be interested in...

Infrared camera optimizes Laser Powder Bed Fusion 3D printing

Artificial Intelligence | trends and developments

3D printer | Additive manufacturing of plastic parts

3D printer metal | Amazing Possibilities

Programming Robots | software and controls