Design assistance for direct screw in light alloy

- Details

- Hits: 8950

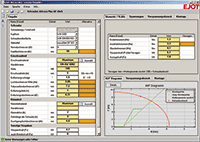

As a support for designers and developers, Ejot offers forecast programs for the pre-design of direct screw connections. With these tools, screw connection parameters can be calculated depending on materials and construction parameters. Numerous practical examples show that these programs can already achieve significant savings during the development phase. The new "Altra Calc" program was specially developed for predicting direct screw connections in light metals.

As a support for designers and developers, Ejot offers forecast programs for the pre-design of direct screw connections. With these tools, screw connection parameters can be calculated depending on materials and construction parameters. Numerous practical examples show that these programs can already achieve significant savings during the development phase. The new "Altra Calc" program was specially developed for predicting direct screw connections in light metals.

But the "ALtracs Plus "screws are specially designed self-tapping fasteners for maximum strength in bolting in light alloy materials up to a hardness of 140 HB Based on an extensive research and development program, the ALtra Calc prediction program developed specifically for this type of screw was developed.

Efficient from direct screwing to screw drive

Efficient from direct screwing to screw drive

Based on the VDI 2230, there are already numerous powerful calculation programs on the market today. However, their fields of application are limited only to the calculation of metric screw connections in metallic materials. For the calculation of self-tapping screw connections, the guidelines of VDI 2230 are therefore only conditionally applicable. In particular, the process of threading and the specific properties of directly bolted materials are not taken into account. These include the various light metals such as aluminum and magnesium. With the development of ALtra Calc, a powerful and precise calculation tool has been developed, which has already proven itself in numerous applications.

For the dimensioning of the screw point calculates ALtra Calc by default with the design policy of ALtracs Plus screw, In practice, however, there are often deviations from these requirements. The effects of these deviations can be simulated within realistic limits with the program. By connecting a material database, you can choose from a variety of different light metal alloys for the calculation of the screw connection.

By specifying the biasing force and the knowledge of the Einschraub- as well as the clamping part material can be reliably determined which screw size and which tightening torque are required in order to achieve the predetermined preload force process reliable. Also, a reversible calculation, so the specification of the tightening torque for determining the biasing force is possible.

In particular, when direct screwing in light metals, the influence of the screw surface on the resulting torques and preload forces is significant. In the forecast program 14 has different screw surfaces, which can optionally be combined with different lubricants. In turn, in combination with the bolted material and the head restraint material, the corresponding friction coefficients are determined, which are finally used for the calculation of the torques and preload forces.

ALtra Calc is also able to calculate various types of failure such as overspeeding or screw breakage and their entry times, for example, the over-tightening force or the pull-out force. With the results, optimal program parameters can be set by the program.