The first robot simulation in the cloud is launched

- Details

- Hits: 6614

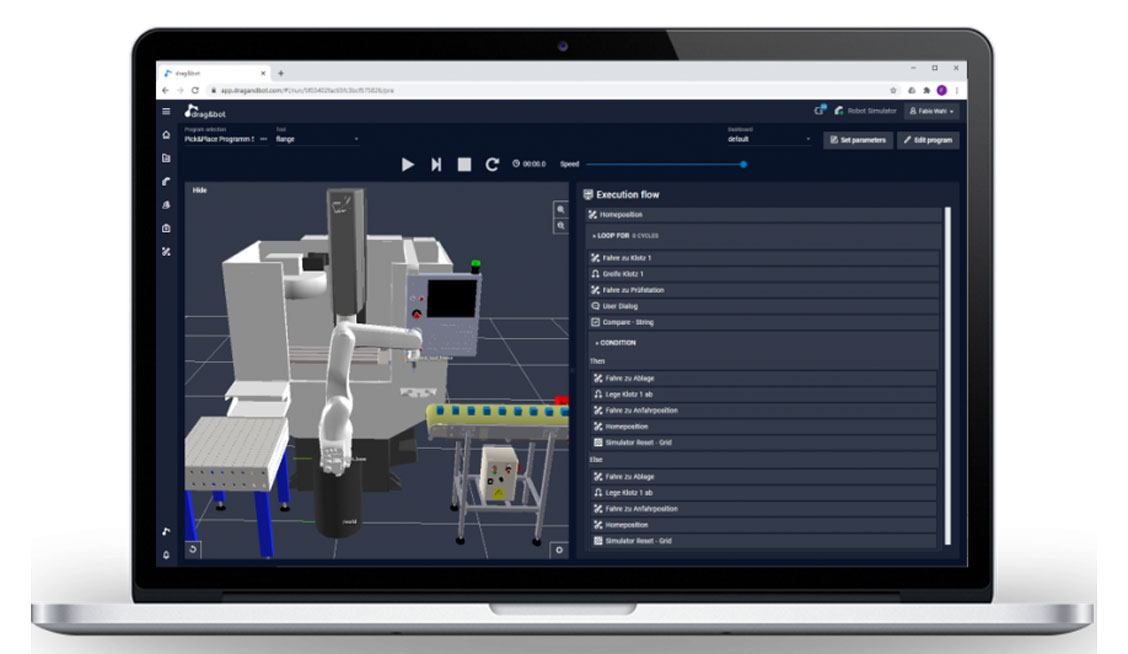

An world first announces the start-up Drag & bot with the free Robot simulation for the significantly easier planning of Automation in factories. CAD models of cell and robot gripper are used to estimate the feasibility, cycle time and accessibility of the application in a few minutes by means of simulation.

The drag & bot robot simulation is the first to be purely cloud-based simulation environment for Industrial robots. In a 3D environment, various Robot with own CAD models of the robot cell and objects for handling with specific grabn Combine into a complete working environment.

Digital twin of the industrial robot

This is how the virtual digital twin of the Robotapplication. He leaves very easily after that Drag-and-drop principle program. Manufacturing companies can thus simulate and evaluate their new automation of machines and systems much faster and free of charge.

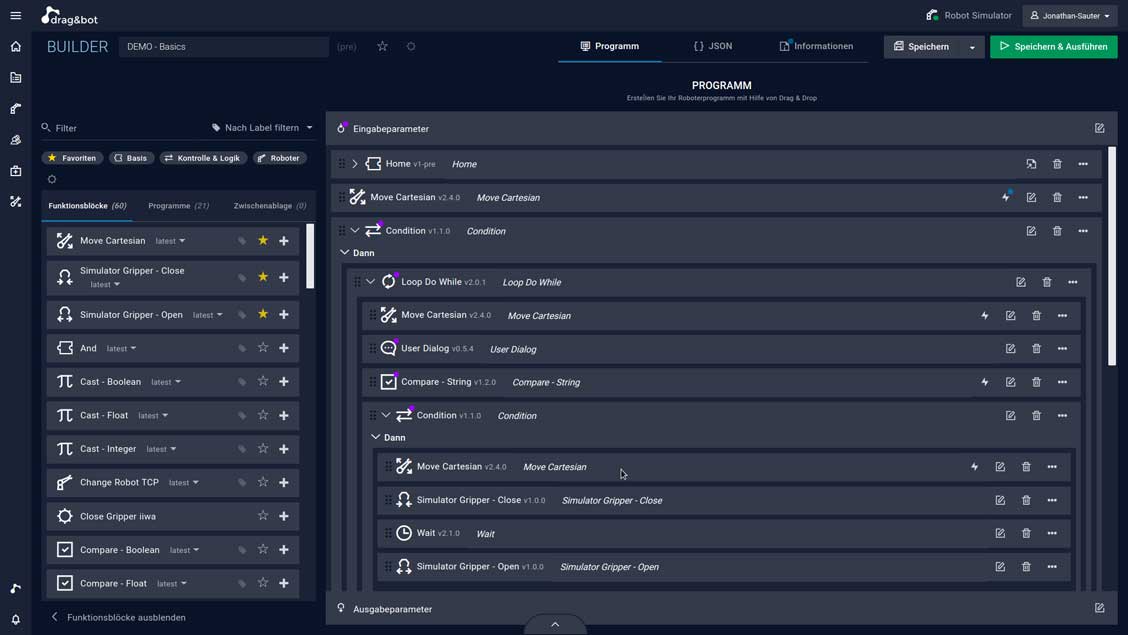

Online tutorials help with the start, specific robot knowledge is not necessary. With just a few clicks, complete robot programming with special functions such as error handling can be created from various function blocks.

The own CAD environment can in the Simulation to get integrated. Each program can be tested with different robots in terms of cycle time and accessibility and the appropriate hardware can be determined. The finished robot programming is then available for download and can be used with the production version of Drag & bot on the real robot.

Do-It-Yourself robotics without specialist knowledge

After the evaluation with the robot simulation, users can use the software Production von Drag & offered to implement their robot cell independently with internal resources. Via plug-and-play interfaces to hardware such as cameras, grippers, force-torqueSensors, Visions, feeders or a PLC system, integration takes just a few minutes, too without special IT know-how.

After the evaluation with the robot simulation, users can use the software Production von Drag & offered to implement their robot cell independently with internal resources. Via plug-and-play interfaces to hardware such as cameras, grippers, force-torqueSensors, Visions, feeders or a PLC system, integration takes just a few minutes, too without special IT know-how.

For the Program structure the user uses the simulation. Real waypoints and paths are given to the robot via a teach panel, an intuitive teach pendant or a 6D Mouse conveyed. After commissioning, users can see the most important KPIs for the system on customizable cockpit panels. In the event of a fault or when retrofitting systems, it can interact directly with the robot.

Almost all common robot applications can be implemented more flexibly than previously possible with Drag & Bot. The software is now compatible with robots from all major manufacturers in Europe such as Yaskawa, Epsons or Stäubli.

Presentation of the robot simulation