Smart Big Data makes the steel industry fit for the future

- Details

- Hits: 4329

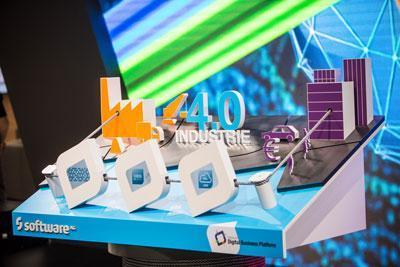

Hannover Messe Hall 7, Stand C04

Hannover Messe Hall 7, Stand C04In addition to the actual production goods, smart factories primarily produce huge amounts of data that are continuously exchanged between self-controlling workpieces, sensors, machines and systems. These hold enormous potential, provided that they are evaluated in real time using big data analysis and are incorporated into the production, planning and maintenance processes. Software AG will demonstrate how this smart big data concept can be implemented in the steel industry using a simulated Industry 4.0 production process at the Bitkom booth.

The German steel industry offers great potential for big data. In the increasingly networked production environment in which the high-tech product steel is made, materials are measured with lasers and checked for material irregularities using a video camera, and vibrations and temperature fluctuations are monitored by a large number of sensors.

In order to filter out important results for production processes from the immense amounts of data that arise, software is used for the complex analysis of large data streams. With the technology of the software company, manufacturing companies can optimize maintenance intervals, for example. For this purpose, data from various sources are aggregated, linked and analyzed - sensor data of the machines, data from production and logistics, on spare parts and the work schedules of the service technicians. This reduces downtimes, which contributes to optimizing the supply chain overall. This enables manufacturing companies to save costs, increase the flexibility of their production processes and the quality of their products.