Technical plastic Ultrason with optimized sliding friction

- Details

- Written by Angela Struck

- Hits: 6876

The BASF presents a new one Engineering plasticwho is particularly good Automotive components protects against contact with hot oil. The polyethersulfone (PESU) Ultrasound E0510 C2TR offers very good tribological properties, dimensional stability even under large temperature fluctuations as well high resistance to oil.

The injection molding type with 10% carbon fiber reinforcement is suitable for use in a temperature range between -30 ° and +180 ° C. Ultrason is easy to process because of the Plastic has a low viscosity and therefore very good flowability.

The Ultrason E0510 C2TR, available globally, allows the production of various oil turning Car components such as oil pumps, pressure valves, oil control pistons and high-speed components in manual gearboxes or automatic transmissions. Applications in alternative drives are also conceivable.

Smaller one millimeter components made from Ultrason E0510 C2TR

Components with thin Wall thicknesses less than 1 mm can be injection molded on the basis of the easy flowability of Ultrason without sacrificing durability, stability or oil resistance. The coefficient of thermal expansion is low at 10,4 (10-6 / K) and enables dimensionally stable components. These can withstand rapid temperature changes from hot to cold without damage.

ASTM G137 tests show that the sliding friction behavior is better than that of other tribologically optimized high-performance thermoplastics. Even at high rubbing speeds, test components show only a low level of abrasion with almost unchanged mechanics and chemical resistance.

The new material combines the proven properties of Ultrason with its own tailor-made properties. Ultrason is therefore extraordinarily resistant to this Chemicals and hydrolysis, has an inherent flame retardancy, height Stiffness and strength consider Temperature stability.

What is Ultrason?

Ultrasound is the brand name of BASF for its portfolio polysulfone with Ultrason S, polyethersulfone with Ultrason E, and polyphenylsulfone with Ultrason P. The high-performance material is used to make lightweight components in the automotive, Electronics and aviation manufactured. Membranes for water filtration and applications in contact with hot water as well food are also predestined for Ultrason. The extraordinary range of properties enables the substitution of metals, Thermosets and Ceramics.

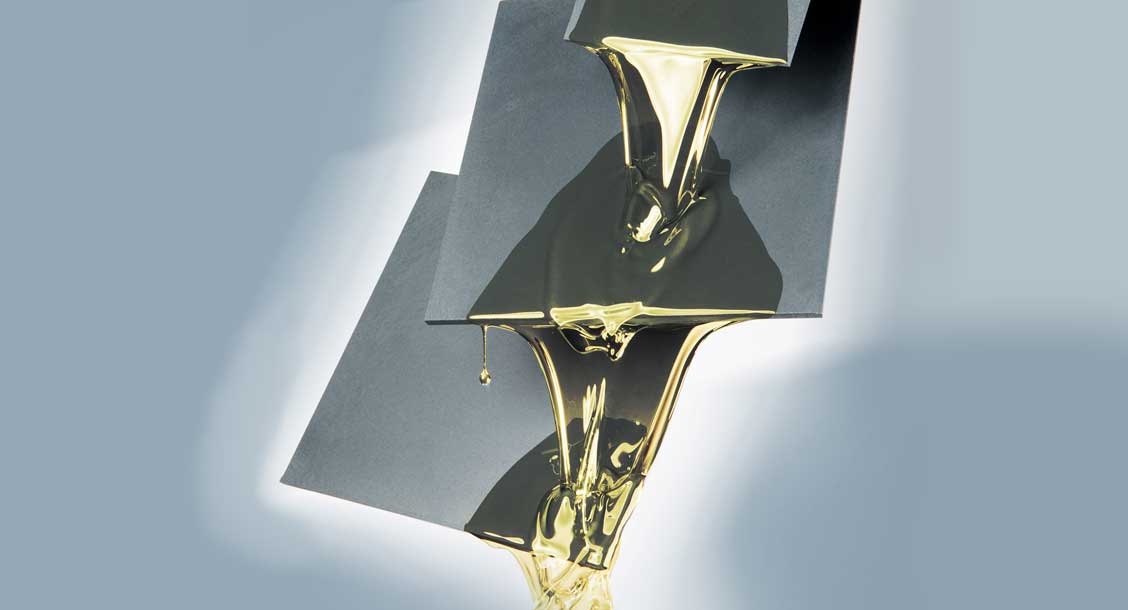

How Oha-Design creates clutter from Ultrason

For Oha design has its innovation based on the Ultrason Clutter manufactured. Yes you've read correctly. The dictionary understands clutter to mean things that are not worth much or are viewed as such - stuff. But Oha-Design gives the term completely new possibilities as a smart, well thought-out one Accesoire for the table.

Plastic welding | New products, processes, accessories

Plastic welding | New products, processes, accessories

Four flat, strip-shaped elements connected by rivet elements can be turned inside out by pushing or pulling at a certain angle. You can do three different stable, three-dimensional forms arise. The converted clutter can then be pressed flat on the table. On the K 2019 there was a live talk about this new development from Ultrason.