Glass-ceramic as a construction material of high quality

- Details

- Hits: 8444

The mica glass ceramic "VITRONIT" from Werkstoffzentrum Rheinbach (WZR) continues to gain popularity among designers and design engineers. Especially when plastics or metals have reached their limits, this porous ceramic material is a popular alternative. It is temperature resistant up to 1000 ° C and can be worked machined using conventional tools. Meanwhile it quality prototypes and series parts with sometimes amazing properties are manufactured.

The mica glass ceramic "VITRONIT" from Werkstoffzentrum Rheinbach (WZR) continues to gain popularity among designers and design engineers. Especially when plastics or metals have reached their limits, this porous ceramic material is a popular alternative. It is temperature resistant up to 1000 ° C and can be worked machined using conventional tools. Meanwhile it quality prototypes and series parts with sometimes amazing properties are manufactured.

The vitreous Vitronit is a modern construction material of high quality. If, for example, high-temperature-resistant components are required that are also intended to insulate electrically, Vitronit is better suited than metals or plastics. Moreover, since the thermal expansion of this glass ceramic is very similar to that of steel, composite solutions can be realized. Other key benefits of Vitronit include good mechanical workability with conventional precision tools.

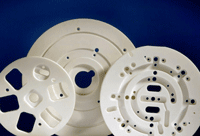

Many designers and product developers have not only prototypes but increasingly also ready-to-install series parts made from Vitronic. Surface qualities of Ra <0,2 µm can be achieved.

After shaping, no burning process is required. Ready-to-install customer parts These include, for example, electro- and heat-insulating molded parts, which have to prove their worth in applications due to their high resistance to frequent temperature changes, corrosion and chemicals. Flanges, charging elements, wearing parts as well as connecting and drive elements (screws, threaded rods) are also produced from this glass ceramic. The constructive potential of vitronite is far from exhausted

The material is standard white, nonporous and non-degassing. The density of the material is 2,66 g / cm3 and its thermal expansion coefficient between 9,5 x 10-6K-1 and 11,3 x 10-6K-1, The thermal conductivity is 1,72 W / mK (at 25 ° C). Particularly noteworthy are the electrical breakdown strength of 12 kV / mm, the flexural strength of 120 MPa and the compressive strength of 450 MPa. With its strength values, vitronite is slightly lower than the ceramic materials aluminum oxide and zirconium oxide.