High temperature seal for fire protection of engines

- Details

- Hits: 5108

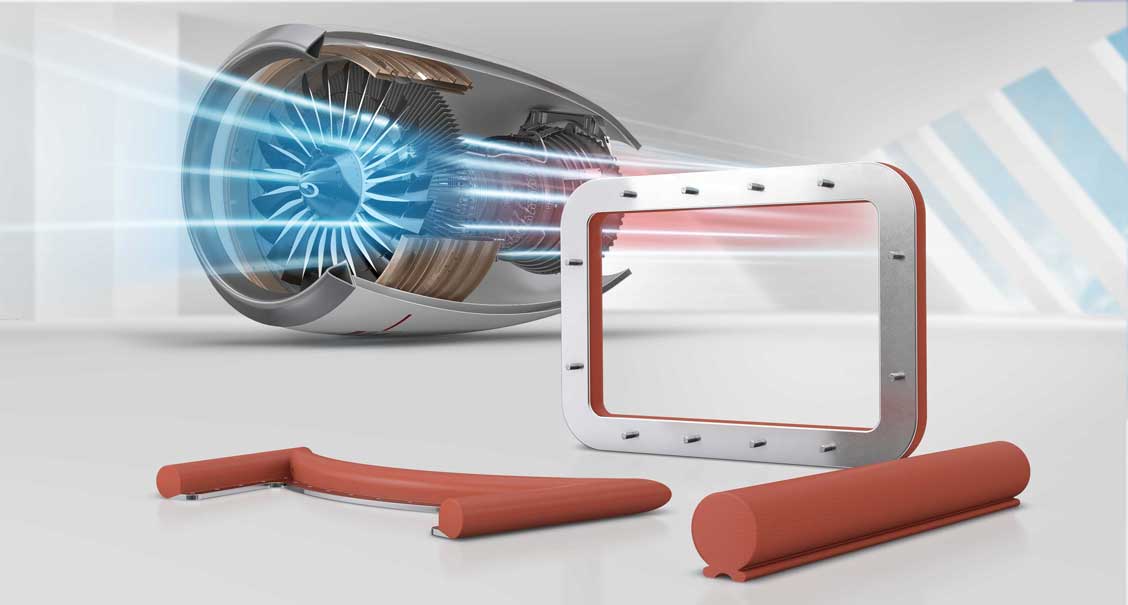

The High temperature seal Ultra High Temp Seal from Trelleborg Sealing Solutions is a particularly heat-resistant seal made of silicone rubber. She was made for use in Jet Engine designed. The higher temperature range of the material enables the development of more efficient engines with reduced fuel consumption than that previously feasible.

"The hotter an engine runs, the more thrust is generated with the same amount of fuel. This makes the engine more efficient with lower fuel consumption. The latest generation engines are therefore operated at 315 ° C and significantly higher temperatures," says Quinn Collett, General Manager Airframe at Trelleborg Sealing Solutions.

For applications with these extreme temperatures, wear special fireproof seals helps to ensure the safety of passengers on board. They are used in engines, fuselages, thrust reversers and pylons. There, the seals act as a barrier and prevent, under normal operating conditions, an air stream from flowing from one area of the aircraft to another. This is an important fire protection measure.

“More importantly, the high temperature seals are used as a precaution and a seal in the event of incidents that could result in a fire. If a fire breaks out, the fire is contained in one area of the aircraft. This allows a safe landing within 15 minutes.

High temperature seal with resistance above 315 ° C

"Up to now there have been no high-temperature fire protection devices on the market that could be used above +315 ° C," says Quinn Collet. "They could not meet the fire protection requirements. Our new high-temperature seals, however, are unique.

"Up to now there have been no high-temperature fire protection devices on the market that could be used above +315 ° C," says Quinn Collet. "They could not meet the fire protection requirements. Our new high-temperature seals, however, are unique.

The patent pendingThe design of the seal overcomes the problems typical of silicone elastomers in terms of relaxation behavior and compression set at high temperatures. This means that our Ultra High Temp Seal is successfully used as a fire protection seal in high temperature aircraft engines. "

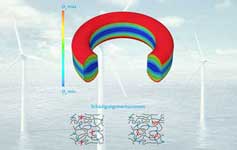

Extensive tests under different load conditions were carried out by the Trelleborg research and development team in order to test the performance and properties of the seal. In heat soaking tests, the high-temperature seal performed better than other fire protection seals. Here was it compression set always below the target value of 15%.

Integration and complex geometries

To manufacture the product, the sealing specialist developed a method for integrating all components and manufacturing complex geometries. Because the Ultra High Temp Seal does not require any thermal protection for the sealing elements, this also resulted Weight saving and reduction in the number of parts. This also made assembly easier.

The static seal for systems and their actual age

The static seal for systems and their actual age

The new high temperature seal is suitable for a temperature range from -40 ° to +315 ° C. Depending on the application, the seal has a service life of 60.000 flight cycles (Take-off, flight and landing). The fire protection seal is also suitable for conventional applications. For example, it is also predestined for use at high temperatures, where a longer service life is required compared to existing solutions, but not all requirements can be met.

The Ultra High Temp Seal meets the requirements of the US federal aviation standard AC20-135 "Powerplant Installation and Propulsion System Component Fire Protection Test Methods and Standards and Criteria" and ISO 2685: 1998 "Aircraft - Environmental Test Procedure for Airborne Equipment - Resistance to Fire in Designated Fire Zones".