Combined adhesive solutions made of ceramic adhesives and glass coatings

- Details

- Hits: 7454

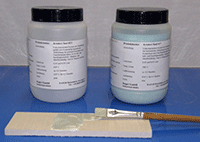

The high-tech adhesives from Kager's Ceramabond range for joining ceramic components withstand extreme conditions of use and high temperatures of up to 1760 ° C. For numerous applications, however, it can make sense to additionally seal and seal the adhesive points with a topcoat. Matched to these cases, Kager offers the matching glass coatings of the "Aremco" family.

The high-tech adhesives from Kager's Ceramabond range for joining ceramic components withstand extreme conditions of use and high temperatures of up to 1760 ° C. For numerous applications, however, it can make sense to additionally seal and seal the adhesive points with a topcoat. Matched to these cases, Kager offers the matching glass coatings of the "Aremco" family.

With the "Ceramabond" product line, there is a large selection of single and multi-component adhesives based on zirconium, aluminum and magnesium oxide as well as silicon carbide for high-temperature applications in furnace construction, metallurgy and power plant technology. They are far superior to conventional epoxies and other organic adhesives, are highly resilient and chemically resistant. A typical example of this is the new ceramic adhesive Ceramabond 890, which is used, among other things, for joining ceramic and graphite components in High vacuum Facilities. Ceramabond 890 can withstand operating temperatures of up to 1370 ° C.

However, in high-temperature and vacuum technology in particular, there are always applications in which the adhesive seams and points produced have to be additionally protected, sealed or sealed. This is done with the help of a Topcoats. So that the user does not have to leave the material family, the manufacturer offers the suitable glass-ceramic coatings in his Aremco range. For example, the products Aremco-Seal 613 and Aremco-Seal 617 are particularly suitable for use as topcoats. These are two modern one-component systems for operating temperatures of up to 620 ° C or 788 ° C.

Numerous tests have been carried out in the in-house technical center, which document the successful interplay of ceramic adhesives and glass coatings. It proves to be an advantage, for example, that a glass-ceramic topcoat not only seals the ceramic surface of the adhesive in a liquid-tight and heat-resistant manner but also makes it impermeable to gas. For these reasons, the various adhesive coating combinations are suitable not only for effective protection of the porous ceramic surfaces but also for the production of gas-tight feedthroughs of wires, tubes or cables in vacuum technology.