Adhesive tapes based on PEN foils

- Details

- Hits: 6490

Polyester film has been used as an insulating material in electrical engineering for more than 40 years. The material thicknesses range from around 4 µm to areas of almost 1 mm. Most of the standard insulating tapes from CMC Klebetechnik are based on polyester films with appropriate adhesive coatings. The expensive polymide has so far been used as a film with a higher thermal load capacity. Adhesive tapes based on PEN film are now closing the gap between these two materials.

Polyester film has been used as an insulating material in electrical engineering for more than 40 years. The material thicknesses range from around 4 µm to areas of almost 1 mm. Most of the standard insulating tapes from CMC Klebetechnik are based on polyester films with appropriate adhesive coatings. The expensive polymide has so far been used as a film with a higher thermal load capacity. Adhesive tapes based on PEN film are now closing the gap between these two materials.

The high-performance materials polyimide (PI) offers impressive performance data, but the price for the films is also significantly higher due to the more complex manufacturing process. Not every application tolerates this increased price - especially not when larger amounts of the insulation film are needed.

The cheaper tapes are based on the PEN film. According to the chemical structure, polyethylene naphthalate is very closely related to polyethylene terephthalate (PET, polyester). PEN differs from PET mainly in its higher glass transition temperature (Tg), greater mechanical strength and good hydrolysis resistance. With regard to haptics and transparency, PENs differ less from PET. Even with respect to adhesive tapes made of the two materials, there are hardly any differences.

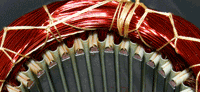

However, the higher glass transition temperature allows the PEN film to be used in applications requiring Class F (155 ° C) materials. Together with the better resistance to hydrolysis, chemicals and UV, the PEN film has become a material that is appreciated among other things by electric motor manufacturers. Higher efficiency, smaller size, and rated load operation create a heat load that can better withstand materials such as Nomex or PEN like traditional PET films. The service life and reliability in case of overload are significantly improved.

The real advantage of PEN but plays in Transformatorenbau. As interlayer insulation can be used for the thermal class B, the known polyester film. When building a transformer of thermal class F, it was necessary to avoid polyimide foils until a few years ago, especially in the non-impregnated coil structure, which made the construction considerably more expensive.

This gap closes the PEN film, providing a more cost effective way to build class F coils and transformers. The film is classified with a flammability rating of UL 94 VTM-2 and achieves a Relative Thermal Index (RTI) = 180 ° C (mechanical), 160 ° C (electrical).

CMC Klebetechnik uses adhesive tapes based on PEN usually use the adhesive already used on the PET film, as long as the tolerated continuous use temperature. Thus, well-known components can be used, which then, for example, in the sealed tube test according to UL 1446 lead to no unexpected results in the tests. Adoption of PEN-based tapes into existing electrical insulation systems (EIS) is thus cost-effective and low-risk.

Currently, PEN films are attracting increasing interest among manufacturers of components for the automotive industry, especially in the context of e-mobility. Higher media resistance plays a particularly important role here - but here, too, the significantly higher price compared to the polyester film dampens the commitment of the development engineers.