New arc process with Einbrandstabilisator

- Details

- Hits: 9669

With four new arc variants for the TPS / i MIG / MAG welding machine platform, Fronius is further exploiting the technical possibilities of its most modern product series: The "LSC Root" and "LSC Universal" characteristics are based on a new algorithm and are characterized by increased arc stability and reduced spatter emission. New welding parameters form the basis for functions such as the penetration stabilizer, which are available for the first time in the industry.

In addition, the developers have significantly improved the arc length correction and dynamic correction functions. Supported by special hardware, the advanced versions of LSC Root and LSC Universal allow the use of longer hose packages with consistently high welding quality. All of these innovations considerably simplify the handling of the welding power source, thus guaranteeing optimum results in welding and soldering, even for less experienced welders.

For LSC (Low Spatter Control), a completely new algorithm has been developed that leverages the high computational power, large memory, extremely fast system bus, and high dynamic wire feed of the company's most recent MIG / MAG welding machine platform. This allows a very stable and low-spatter arc.

Root welding with reduced path energy

The advances achieved in root welding, for which the LSC Root was developed, are particularly clear. LSC Root guarantees a very good root penetration and high melting performance at reduced track energy. Unlike conventional MAG welding, this makes it possible for the first time to weld even in a falling position without having to accept binding errors. This significantly simplifies root welding for the user. In addition, the protective gas loss could be reduced by a new generation of burners by up to 3%.

The advances achieved in root welding, for which the LSC Root was developed, are particularly clear. LSC Root guarantees a very good root penetration and high melting performance at reduced track energy. Unlike conventional MAG welding, this makes it possible for the first time to weld even in a falling position without having to accept binding errors. This significantly simplifies root welding for the user. In addition, the protective gas loss could be reduced by a new generation of burners by up to 3%.

The arc characteristic LSC Universal is particularly suitable for the welding of fillet welds, corner seams, lap seams as well as for fill and cover layers and for soldering.

Consistent and deep penetration

The users of the LSC arcs benefit from the new burn-in stabilizer. When activated, it keeps the burn-in constant with stick-out fluctuations using the new wire feed speed control. This is freely adjustable by the user. The positive effect is particularly evident in fillet welds, which are to be welded in a rising position with a pendulum motion. Here, the stabilizer ensures a consistent and deep penetration even with external disturbances. In this case, very good results can be achieved even with less expensive solid wires.

In addition, Fronius has further developed the Arc Length Correction and Dynamic Correction functions already supported by its predecessors and valued by welders. For example, you can now also set the arc pressure using the dynamic correction in LSC Root. Extended functions, which ensure a high seam quality at the welding start and end, complete the LSC package.

To ensure that longer hose packages, such as those used in pipe and container construction and robot-assisted welding, can be used without sacrificing quality, the welding specialist has developed additional hardware that reduces the negative influence of increased inductance in the welding circuit. The advanced versions of the arc characteristics LSC Root and LSC Universal are available for the power source equipped with it.

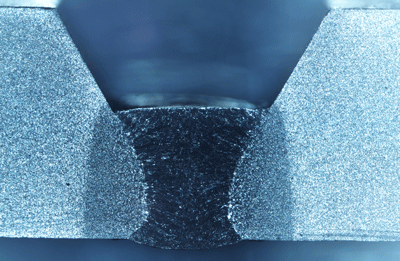

Picture above: Cross-section of a root seam welded with LSC Root with deactivated burn-in stabilizer. Wire diameter: 1,2 mm, additional wire: G3Si1, wire feed: 3,6 m / min