Highly dynamic flow drill screws with high contact pressure

- Details

- Hits: 10162

As a cold joining method for steel and aluminum, the so-called Flow drill screws by. In addition to high speeds, this also requires high contact pressures, such as those used in the screw systems from WSM automation deliver with the highest dynamics and precision.

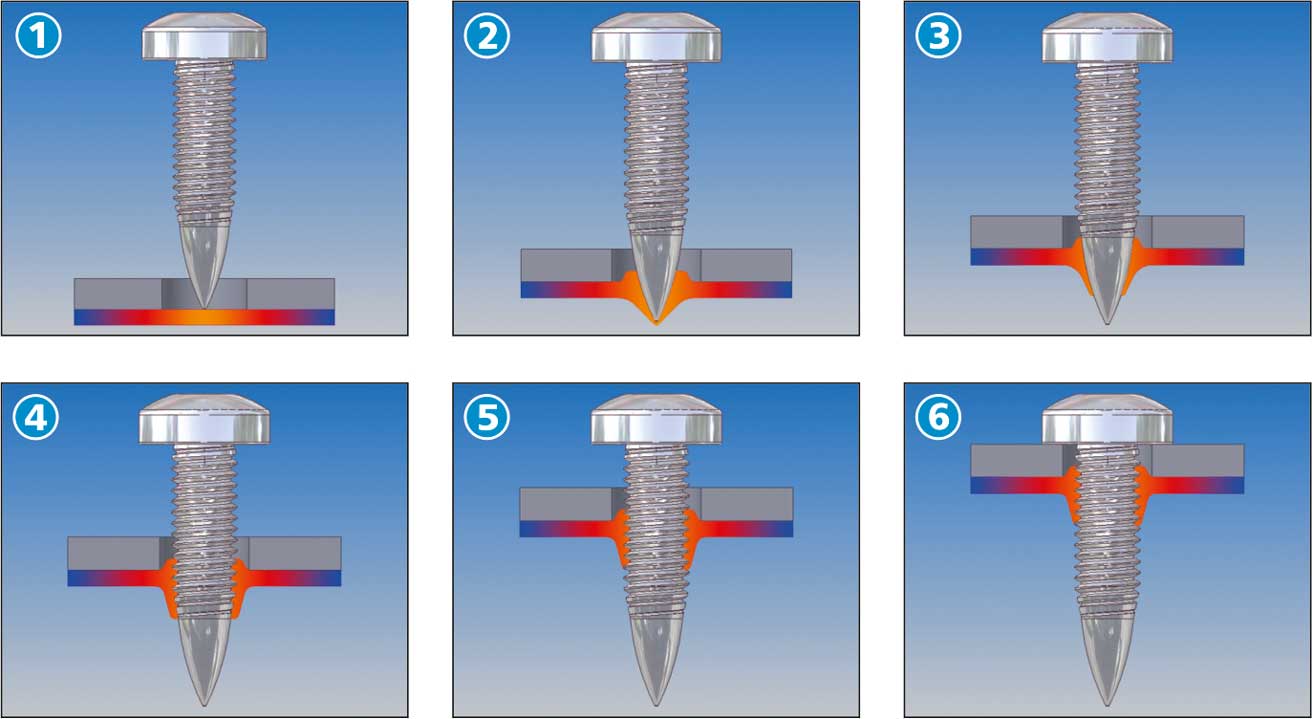

The flow drill screws or flow hole forming screws has so far mainly been used in thin sheet processing. The workpieces are connected to one another with a one-sided joining direction without a pilot hole. The screw forms a flow hole with a true-to-gauge nut thread without cutting with increasing high speed and contact pressure. The high support part in the thread creates a high-strength connection. In addition, a Flowform screw can later be replaced by a conventional metric screw if necessary.

Thanks to their high dynamics, the screw systems for flow hole forming screw meet the special requirements for processing Flowform screws. These screwing units are also already designed for the increasingly precise target specifications required in this context, which have to be met in ever shorter cycle times. Regardless of the specification for a screw connection such as torque, angle of rotation, screw-in depth or the active detection of the screw head support, each goal can be achieved extremely precisely and highly dynamically with the screwing units.

Controls for flow drill screws

While conventional screwdriver controls measure the torque at 1 kHz, 2 kHz is the standard for this version, and there are even special solutions Measurement rates up to 10 kHz possible. This means that even the smallest changes in torque can be recorded quickly. The high-quality screwing units accelerate from standstill to 1500 min-1 and brake from the same speed to a standstill - and this within a maximum rotation angle of 10 degrees.

Efficient from direct screwing to screw drive

Efficient from direct screwing to screw drive

In practice, the values are usually well below that and are therefore much more dynamic than usual on the market not only when accelerating and braking, but also when changing the tightening level. Particularly available for processing flow drill screws Drives with an output speed of up to 4000 min-1 is available for storage, management and analysis.