Efficient material for the next generation of power electronics

- Details

- Hits: 4819

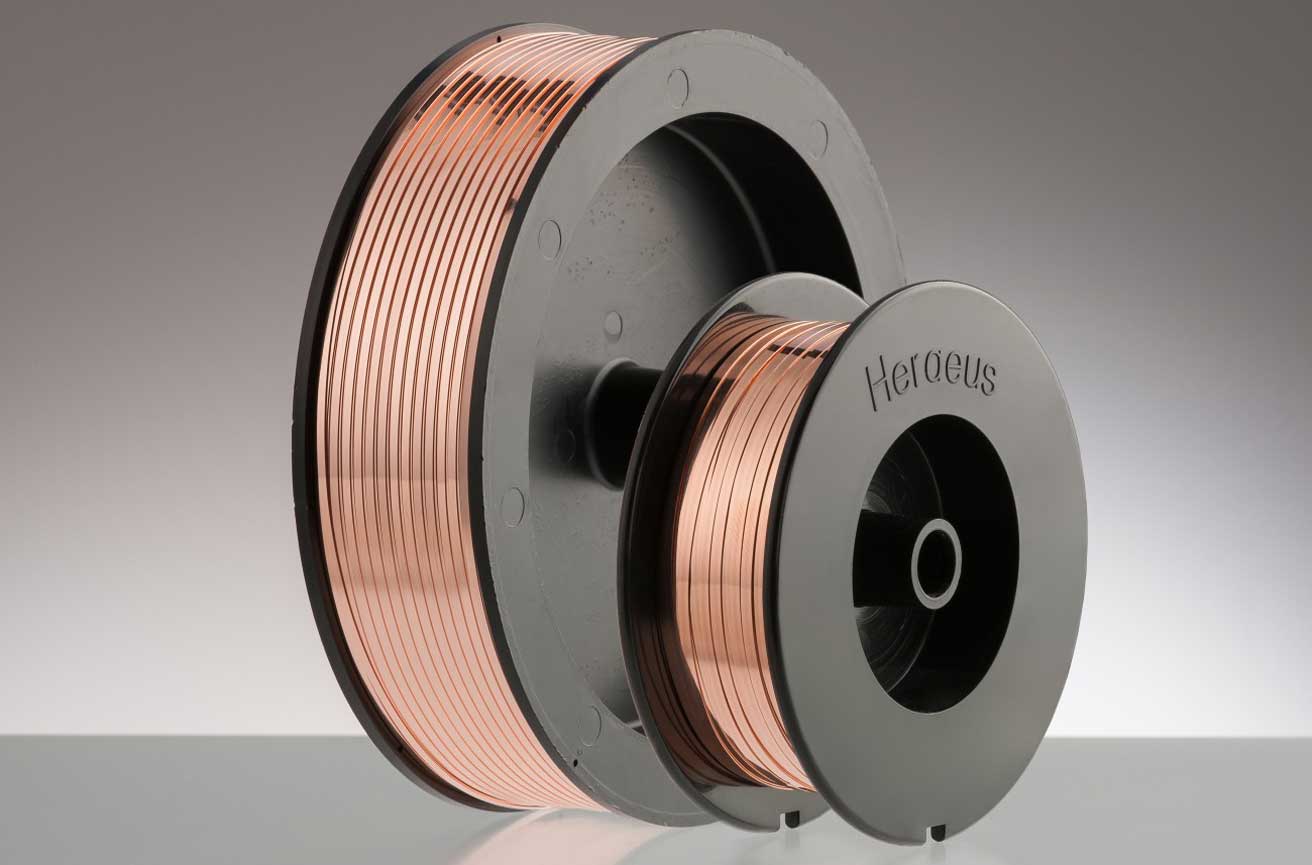

Heraeus Electronics represents a new material for the next generation of power Electronics in front. The Powercusoft product family is expanded to include a Copper bond ribbon expanded. With it, power modules can be designed and manufactured more reliably, effectively and cost-effectively.

Powercusoft Ribbon was developed for the surface contacting of power semiconductors with a wide band gap, so-called Wide Bandgap Semiconductors, based on Silicon carbide SiC optimized. With this generation of bonding tapes, the full potential of the new SiC chips can be exploited.

Power electronics with copper versus aluminum

Copper offers better thermal, electrical and mechanical properties than aluminum wires and aluminum ribbons. Copper heats up less than aluminum and can withstand higher temperatures in power electronics.

That extends the Lifespan and improves the reliability of power electronics. The new copper material can withstand temperatures of up to 250 ° C. In tests, copper ribbons lasted ten to twenty times longer than aluminum - with a simultaneous increase in the energy density in the module.

Copper as infinitely recyclable for sustainable building

Copper as infinitely recyclable for sustainable building

"SiC semiconductors are in the fast lane due to their high power density" says Christian Kersting, Product Manager Power Bonding Wires at Heraeus Electronics. "In order to be able to use the advantages of these products, module manufacturers need powerful assembly and connection technologies."

Compared to copper wires, ribbons are cheaper because one ribbon replaces several copper wires. Manufacturers can optimize the manufacturing costs per module with increasing output. Depending on Module design it is even possible to produce twice as many modules per hour.