for the optimal coating

Coatings by painting, powder coating as well as PVC coatings, surface refinement, dosing, lasering give robustness and shine

Image: Heraeus

for the optimal coating

Coatings by painting, powder coating as well as PVC coatings, surface refinement, dosing, lasering give robustness and shine

Image: Heraeus

Quality products have high quality Surfacesso that they last a long time and are visually appealing. Corrosion protection, wear protection and decorative properties place special demands on the surface. We report in our section Surface Technology about coatings by painting, powder coating as well as PVC coatings, surface finishing, dosing, lasers and others Processthat give the surface robustness and shine, for example, or simply make it feel appealing. Our surface technology is aimed at designers and development engineers who manufacture their components from aluminum, steel, stainless steel and much more. want to provide the best surfaces.

Find out about news on surface technology at Protection and for the optics Of your new products!

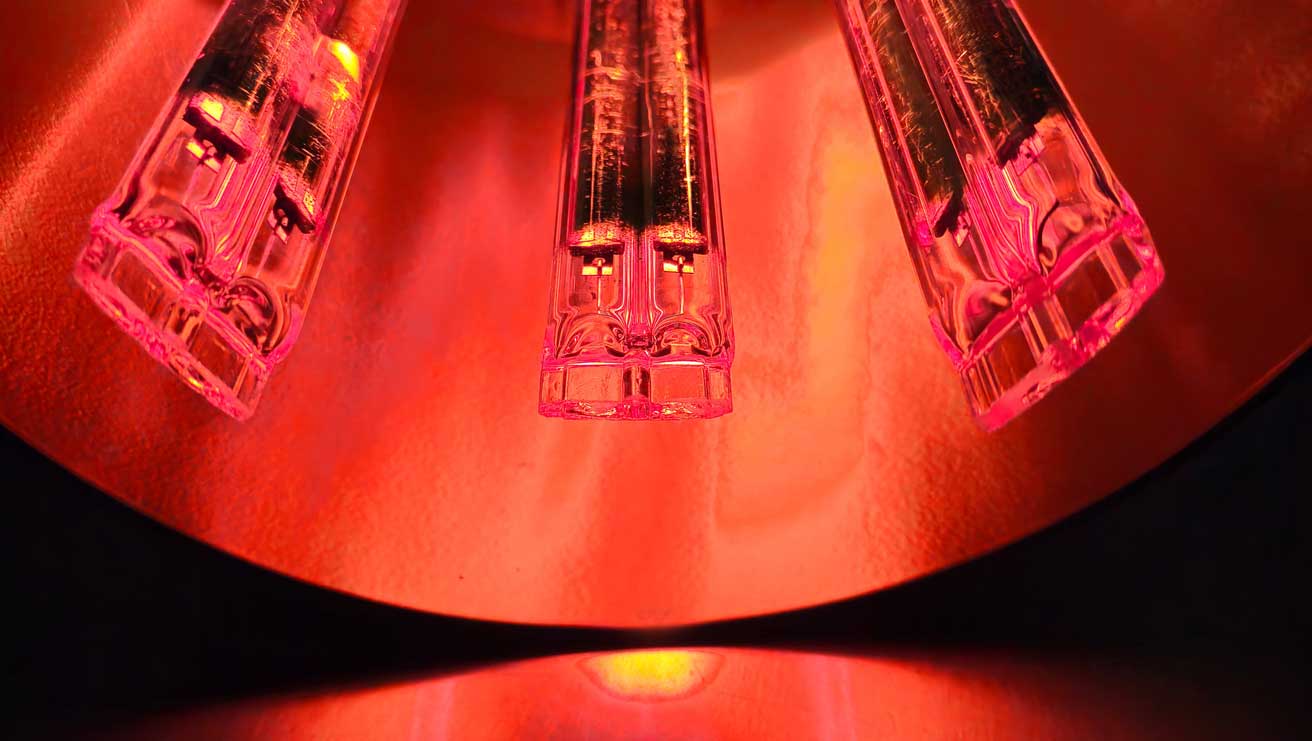

Infrared heater from Excelita's Noblelight play a crucial role in modern industry. With their ability to deliver heat precisely and efficiently, they optimize numerous industrial processes, from material processing until final production. Find out how Infrared Heaters Make industrial applications more efficient and of better quality and why they are considered a key technology for energy-efficient heating processes.

Plasmatreat has with his Openair plasma technology an innovative surface coating for Surfacespretreatment of Plastic, Metal or Glass developed. Due to its activation power, the Openair plasma increases the surface energy significantly. Two application examples illustrate the innovative development for plasma pretreatment.

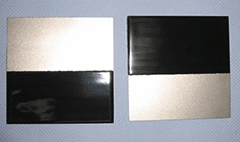

As was common in the industry at the beginning, aluminum components were previously powder coated black. After a short time in use, the parts returned for maintenance showed clear signs of wear. They no longer looked like new. Inspired by a consultation with an AHC sales representative, Antonio Tundo decided to take a new path for the Grip Factory products and have the aluminum parts of his camera equipment hard-anodized using the "hard coat" process.

As was common in the industry at the beginning, aluminum components were previously powder coated black. After a short time in use, the parts returned for maintenance showed clear signs of wear. They no longer looked like new. Inspired by a consultation with an AHC sales representative, Antonio Tundo decided to take a new path for the Grip Factory products and have the aluminum parts of his camera equipment hard-anodized using the "hard coat" process.

With the "sol-gel" coatings of its new "Cercoat" product line, WZR Ceramic Solutions can specifically optimize the surface quality of metallic, glass and polymer workpieces and semi-finished products. The range of properties that can be achieved is enormous, since the coatings, which are available in three groups, can be modified in many ways. Manufacturers, developers and suppliers are thus offered considerable potential for improvement in terms of surface technology.

With the "sol-gel" coatings of its new "Cercoat" product line, WZR Ceramic Solutions can specifically optimize the surface quality of metallic, glass and polymer workpieces and semi-finished products. The range of properties that can be achieved is enormous, since the coatings, which are available in three groups, can be modified in many ways. Manufacturers, developers and suppliers are thus offered considerable potential for improvement in terms of surface technology.

The GSO Surface Technology uses over 1000 different paints every year to coat components for a wide variety of industries. The trend is towards more individual products with smaller batches and frequent color changes. Automation and the early one Coating thickness measurement with the non-contact testing system Paintchecker mobile from optisense play a key role in maintaining the quality level and increasing productivity.

In order for railway trains to operate optimally, all moving mechanical parts must meet demanding requirements for performance and maintenance. Robust, corrosion-protected components are essential for the long-term reliable functioning of the rolling stock. The great Rollon The product portfolio with corrosion-protected linear and telescopic guides as well as guides made of stainless steel offers suitable solutions for all rail technology.

In order for railway trains to operate optimally, all moving mechanical parts must meet demanding requirements for performance and maintenance. Robust, corrosion-protected components are essential for the long-term reliable functioning of the rolling stock. The great Rollon The product portfolio with corrosion-protected linear and telescopic guides as well as guides made of stainless steel offers suitable solutions for all rail technology.

SIC Marking introduces the “i103 HD-Laser” laser marker, with which direct markings can be produced precisely on metal and plastic parts thanks to the short pulse fiber laser used. Its technical properties make it possible for metals and plastics to be labeled with even more contrast and legibility - even with less than optimal surfaces.

SIC Marking introduces the “i103 HD-Laser” laser marker, with which direct markings can be produced precisely on metal and plastic parts thanks to the short pulse fiber laser used. Its technical properties make it possible for metals and plastics to be labeled with even more contrast and legibility - even with less than optimal surfaces.

Ceramic Polymer has launched a new, solvent-free interior tank coating with extremely high protective functions. Thanks to the special physical properties of this new development, stainless steel is reliably protected against severe corrosion damage. The new development is absolutely resistant to a large number of chemicals and gases up to a permanent operating temperature of 150 ° C.

Ceramic Polymer has launched a new, solvent-free interior tank coating with extremely high protective functions. Thanks to the special physical properties of this new development, stainless steel is reliably protected against severe corrosion damage. The new development is absolutely resistant to a large number of chemicals and gases up to a permanent operating temperature of 150 ° C.

Components that are to be coated in the KTL process are generally hung or plugged into special devices before they are immersed in the various baths. In addition to constructive measures in the design of the workpieces, the construction of these product carriers also contributes to a good coating result. That is why Ebbinghaus Styria Coating pays particular attention to the design and manufacture of these product carriers.

Components that are to be coated in the KTL process are generally hung or plugged into special devices before they are immersed in the various baths. In addition to constructive measures in the design of the workpieces, the construction of these product carriers also contributes to a good coating result. That is why Ebbinghaus Styria Coating pays particular attention to the design and manufacture of these product carriers.

The "Preeflow Eco-PEN300 1K" dispenser from Viscotec ensures optimal surface technology processes and low material consumption in automated use. Applications can be found everywhere: for example on steering wheels and grilles for cars, excavators and tractors, on coffee machines, refrigerators and other household appliances.

The "Preeflow Eco-PEN300 1K" dispenser from Viscotec ensures optimal surface technology processes and low material consumption in automated use. Applications can be found everywhere: for example on steering wheels and grilles for cars, excavators and tractors, on coffee machines, refrigerators and other household appliances.

Whether direct and indirect light accents, colored accent strips or mirror surfaces: With an innovative plastic coating, components in and around the vehicle can be designed in a variety of ways. Benseler shows how wide the range of what is feasible with plasma vacuum coatings (PVD) in combination with UV paint is.

Whether direct and indirect light accents, colored accent strips or mirror surfaces: With an innovative plastic coating, components in and around the vehicle can be designed in a variety of ways. Benseler shows how wide the range of what is feasible with plasma vacuum coatings (PVD) in combination with UV paint is.

Datalogic presents its new "Arex 400" laser. Together with the “Marvis” software, the user receives a complete traceability solution. The Arex series is a family of compact fiber lasers for high-speed marking on metal and plastic for the automotive and electronics industries.

Datalogic presents its new "Arex 400" laser. Together with the “Marvis” software, the user receives a complete traceability solution. The Arex series is a family of compact fiber lasers for high-speed marking on metal and plastic for the automotive and electronics industries.