for material-to-substance joining

MAG welding, MIG welding, TIG welding and ultrasonic welding as well as soldering as a thermal process

Image: Fronius

for material-to-substance joining

MAG welding, MIG welding, TIG welding and ultrasonic welding as well as soldering as a thermal process

Image: Fronius

For cohesive Connection Technology that counts in mechanical and plant engineering Solder and welding. Welding processes such as arc welding with MAG welding, MIG welding or TIG welding or ultrasonic welding are used here. We report on that welding processeswith which workpieces made of steel, sheet metal, aluminum and other metals as well as plastic are connected to one another via a weld seam. In addition to welding, soldering also stands for joining the metal sheets as thermal process in the focus of the connection technician.

Here you will find the latest products, systems and technologies for welding and soldering. Find out about the news of the material connection technology!

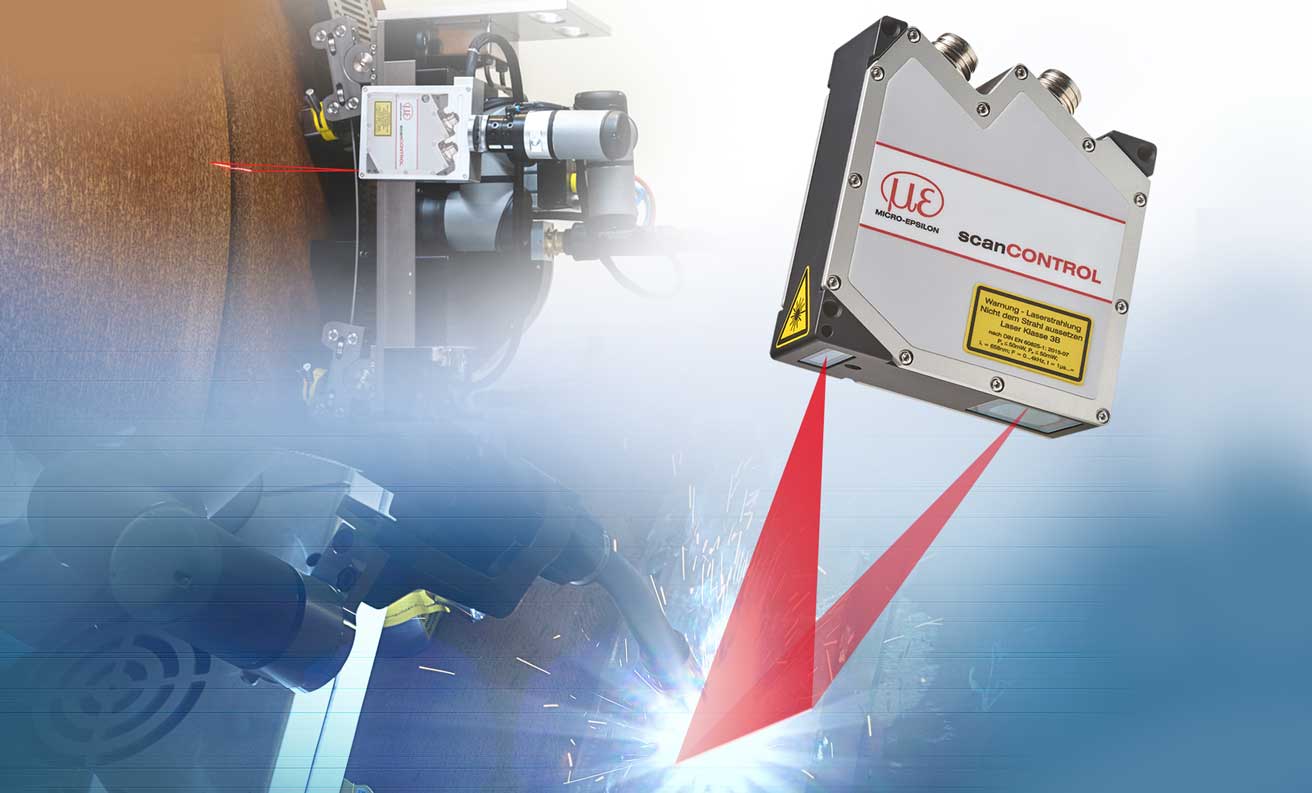

inrotech A / S from Denmark achieves the optimum with its special welding robot Inrotech-Crawler Weld in the fully automated process. This is done by calculating the welding process in advance. When running the welding does the Robot on the exact measured values of the powerful laser Profile scanner from Micro-Epsilon back. The scanners are light, precise and compact.

Yaskawa is expanding the "Arcworld" portfolio with two very compact turnkey, robot-based inert gas welding cells. Motoman robots, positioners, controls and power sources are combined in a space-saving and ready-to-use platform on one platform. The robot cell can be moved quickly and easily if necessary.

Yaskawa is expanding the "Arcworld" portfolio with two very compact turnkey, robot-based inert gas welding cells. Motoman robots, positioners, controls and power sources are combined in a space-saving and ready-to-use platform on one platform. The robot cell can be moved quickly and easily if necessary.

Many companies become lateral entrants in the mass production of Respirators, With the Ultrasonic cutting and welding Technology, respiratory masks can be mass-produced in a particularly resource-saving manner. Telsonic has adjusted to the current situation. The specialist in ultrasonic cutting and welding offers tailor-made equipment for the production of respiratory masks with significantly reduced delivery times.

When connecting from Plastics that sits down Ultrasonic welding increasingly common in many sectors. It's safe, efficient, energy saving, accurate, eco-friendly, sustainable and more. Here we present innovations such as a new process in combination with the Thermosonic bonding. Or read about how it compares to what has been predominantly used up to now heat sealing performs and how it improves the quality of the connection of critical plastic parts in the body fabricationg ensures.

With four new arc variants for the TPS / i MIG / MAG welding machine platform, Fronius is further exploiting the technical possibilities of its most modern product series: The "LSC Root" and "LSC Universal" characteristics are based on a new algorithm and are characterized by increased arc stability and reduced spatter emission. New welding parameters form the basis for functions such as the penetration stabilizer, which are available for the first time in the industry.

The “Phasis one” ultrasonic testing device from Vogt Ultrasonics guarantees reliable spot weld testing with imaging using phased array technology. With a physical resolution not previously achieved by comparable devices, there is a precise statement about the diameter of the weld nugget and the remaining wall thickness in the area of the weld.

The “Phasis one” ultrasonic testing device from Vogt Ultrasonics guarantees reliable spot weld testing with imaging using phased array technology. With a physical resolution not previously achieved by comparable devices, there is a precise statement about the diameter of the weld nugget and the remaining wall thickness in the area of the weld.

In order to connect the plastic components of the opening mechanism with the aluminum of the lid of the resealable lids for the beverage cans developed by Xolution, a joining process had to be found that works quickly and precisely and enables short cycle times for high throughput rates. After extensive tests, the choice fell on ultrasonic welding systems from Telsonic.

In order to connect the plastic components of the opening mechanism with the aluminum of the lid of the resealable lids for the beverage cans developed by Xolution, a joining process had to be found that works quickly and precisely and enables short cycle times for high throughput rates. After extensive tests, the choice fell on ultrasonic welding systems from Telsonic.

Fronius recently brought the CMT welding process to the company's most modern welding power source, the TPS / i. With the second generation of the cold arc, robot-assisted welding can be carried out in many applications with unprecedented quality, simplicity and process reliability. Because of these advantages, the steel producer and automotive supplier Voestalpine decided to be the first to use the advanced CMT technology in series production.

Fronius recently brought the CMT welding process to the company's most modern welding power source, the TPS / i. With the second generation of the cold arc, robot-assisted welding can be carried out in many applications with unprecedented quality, simplicity and process reliability. Because of these advantages, the steel producer and automotive supplier Voestalpine decided to be the first to use the advanced CMT technology in series production.

Telsonic presents the new control software "Telsoflex" with a new 12 "touch panel for welding and cut-off welding with ultrasound, which makes the ultrasound systems of the USP and TSP series fit for Industry 4.0.

Telsonic presents the new control software "Telsoflex" with a new 12 "touch panel for welding and cut-off welding with ultrasound, which makes the ultrasound systems of the USP and TSP series fit for Industry 4.0.

Will that be Glue from Plastic not permanently strong enough, that often happens Plastic welding used as a joining process. It is used as an alternative, particularly for plastics that are difficult to glue, such as polypropylene PP or polyethylene PE. A welding device or welding machine is used for this. Below we present the New developments for the thermal joining process as well as for plastic welding with laser or ultrasound.

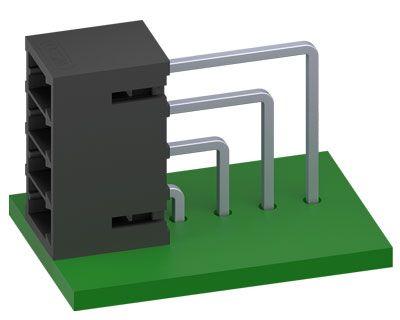

Weco manufactures PCB terminals with overlong, angled or double solder pins. Produced at the headquarters in Hanau, the pens can be applied to a straight or angled surface. This guarantees an optimal casting of boards with components without any restrictions. The products that are used in heating technology, for example, offer a wide range of variants.

Weco manufactures PCB terminals with overlong, angled or double solder pins. Produced at the headquarters in Hanau, the pens can be applied to a straight or angled surface. This guarantees an optimal casting of boards with components without any restrictions. The products that are used in heating technology, for example, offer a wide range of variants.