Buffer and elastomer springs can dampen and feathers

- Details

- Hits: 14735

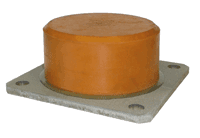

Weforma presents particularly resilient and long-lasting PUR damping and spring elements for tight installation spaces or applications with particularly strong vibrations. The various elements are specially designed for their intended use and, due to their design and material, can be used as spring or damping elements as well as spring-damper elements.

Weforma presents particularly resilient and long-lasting PUR damping and spring elements for tight installation spaces or applications with particularly strong vibrations. The various elements are specially designed for their intended use and, due to their design and material, can be used as spring or damping elements as well as spring-damper elements.

The crane buffers are used at the end stops of cranes, crane runways or so-called cats, when due to the speed or the installation space hydraulic dampers can not be used. Drop buffers are used in accordance with DIN EN 81 for lifts with slow speeds up to 1,2 m / s. There are hydraulic dampers for higher-speed freight or passenger lifts. Elastomeric springs are particularly suitable for vibration isolation when storing sensitive goods and products. In mechanical and plant engineering, they are an economical alternative for damping at slow speeds.

Whisper-quiet elevator brake secures elevators and escalators

Whisper-quiet elevator brake secures elevators and escalators

All versions have in common is the very high dynamic load capacity: The material has only a small transverse strain and is therefore also suitable for extreme requirements. In heavy industry, mining or mines, the products ensure the best possible safety and reduce the stress on machine and system parts. Since they have progressive characteristics, which allow - at comparable height - a longer travel than alternative impact absorbers, low deceleration values are possible and braking forces are effectively reduced. In addition, the necessary bearing forces are lower with the same energy consumption.

The elastomer springs are suitable for ambient temperatures from -30 ° to + 80 ° C. Even at high temperatures their elasticity is fully preserved. They are resistant to oils and fats as well as to a variety of chemicals and ozone. Further advantages of the PUR damper are the particularly long service life and the long-term, complete freedom from maintenance. In addition, no material fatigue occurs and even with an overload, the elastomer springs do not break. Leakage is technically impossible.