Miniature stepper motor positioned in the tightest of spaces

- Details

- Hits: 9647

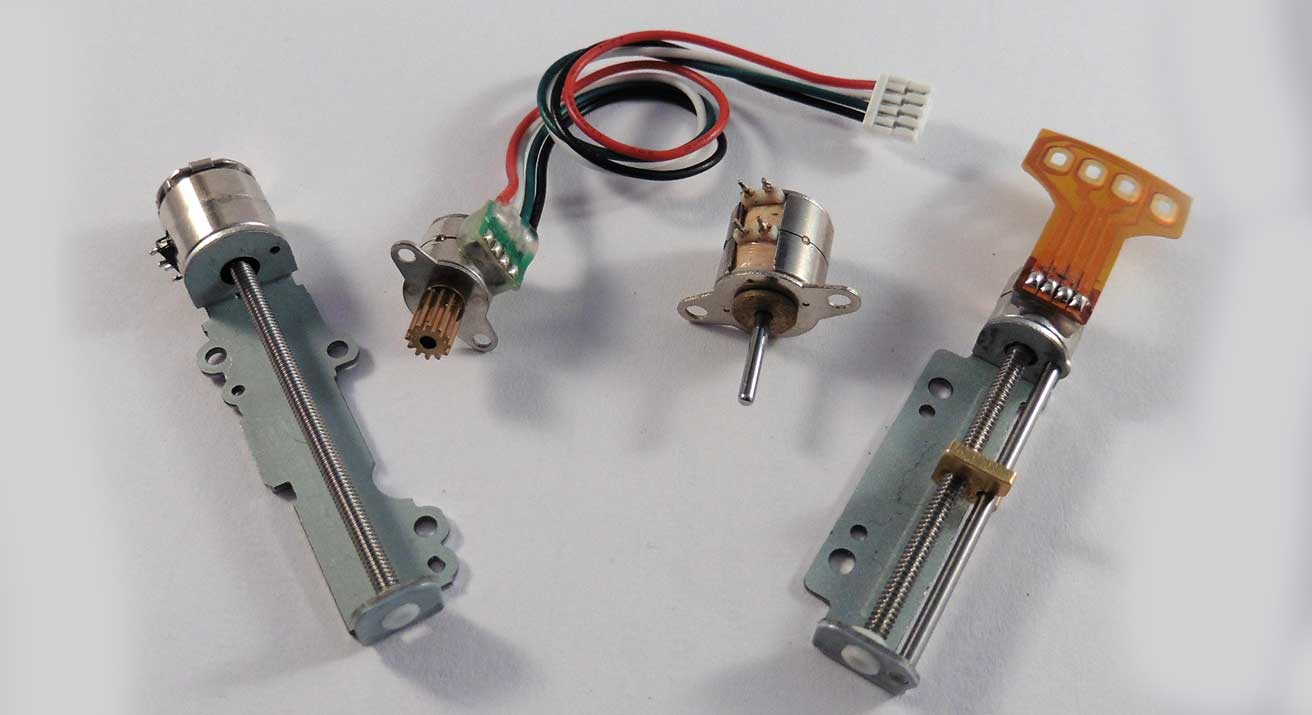

koco Motion expands its family of miniaturized drives. The new Miniature stepper motor VSM08-15 combines small footprint with very high performance. This allows the simplest positioning tasks to be implemented. Thanks to the compact external dimensions of only 8 mm in diameter and 7,9 mm in length, the small stepper motors can be accommodated even in the smallest of spaces.

The simple control of the 2 phase permanent magnet (PM) Stepper motor is done using simple controllers that only need to switch low voltages and currents. The high acceleration and the resulting high dynamics of the stepper motors keep the running times for positioning tasks low, even over larger distances.

The Areas of application the miniature Linear motoren can be found in Medical Technology, microscopy, Safety Technology and wherever mobility, size, weight or accuracy of the device and thus mass and power supply play a role. Specifically, the VSM08-15 miniature stepper motor is suitable for implementing valve adjustments in the Automation or for display devices in the Automotive industry.

Miniature connectors for safe signal transmission

Miniature connectors for safe signal transmission

All connections are housed in the small design of the micro stepper motors. The holding torque of the stepper motors is 0,25 mNm and the dynamic torque is up to 0,2 mNm. Of the Open loop operation enables quick and easy implementation. In the standard version, the miniature stepper motors can withstand operating temperatures from -10° to +60 °C. Numerous modifications such as connection technology or mechanical add-on parts such as pinions and mounting plates are available on request.

Small step angle of only 18 degrees

The step angle of 18° gives an idea of how filigree work has to be done in order to 20 full steps per revolution to reach. This means that the stepper motor can be positioned very precisely in full-step mode alone. Using a micro step resolution, positioning can be refined many times over and the concentricity is positively influenced. The small step angle of this design allows very good working with the detent torque when the position has been reached in full step and the motor is to be kept currentless to save energy.

The step angle of 18° gives an idea of how filigree work has to be done in order to 20 full steps per revolution to reach. This means that the stepper motor can be positioned very precisely in full-step mode alone. Using a micro step resolution, positioning can be refined many times over and the concentricity is positively influenced. The small step angle of this design allows very good working with the detent torque when the position has been reached in full step and the motor is to be kept currentless to save energy.

Using a spindle can of miniature stepper motor be converted into a linear drive and achieve high dynamics as an actuator with a spindle pitch of 0,5 mm per revolution. The drives can also always be customized.

Koco Motion exhibits at Hannover Messe.

You might also be interested in...

Koco Motion | System house for drives

DC motor and other drives for medical technology

Stepper motor linear actuators galore