Mini-brake for robot joints, climb in space

- Details

- Hits: 7587

The robust, energy-efficient climberrobot “Space Climber” was designed for missions in difficult terrain. An essential component of his musculoskeletal system are the intelligent, powerful joints. Especially for such a joint Mayr Antriebstechnik Mini brake developed. It impresses with its small dimensions and increases the energy efficiency of the robot. At the German Research Center for Artificial intelligence (DFKI) this robot system is now being further developed.

Contents

- The Space Climber in action

- Save energy with a secure hold

- Robot lady Aila with memory

- Brakes proven millions of times in the field

The Space Climber in action

In the future, it will be able to explore planets independently and build infrastructure there with its gripping arms. We're talking about the new multi-part Walking robot, which scientists at the Robotics Innovation Center at DFKI are currently developing. The robot, which resembles a praying mantis, is being created as part of the “Limes” project, which runs until the end of April 2016 and is funded by the German Aerospace Center (DLR).

Thanks to its morphology and different walking patterns for different ground conditions, it will master craters and boulder fields and manipulate them with its forelegs. By learning from his experiences, he should be able to act purposefully. The DFKI With its locations in Kaiserslautern, Saarbrücken, Bremen and Berlin, is the world's largest research center in the field of artificial intelligence.

Thanks to its morphology and different walking patterns for different ground conditions, it will master craters and boulder fields and manipulate them with its forelegs. By learning from his experiences, he should be able to act purposefully. The DFKI With its locations in Kaiserslautern, Saarbrücken, Bremen and Berlin, is the world's largest research center in the field of artificial intelligence.

Model ant with six legs

An already tried and tested one Space robots of the DFKI and a forerunner of the Limes project is the climbing robot Space Climber. In its morphology it resembles its natural model, the ant. The free-climbing robot has six legs that help it explore crater walls, rock crevices or gorges, for example.

In its basic position, the robot is around 80 cm wide, 1 m long and 20 cm high. Its weight is around 25 kg. The Space climber safely handles steep, irregular slopes with gradients of up to 80% and moves at a speed of 0,3 m/s. The most important components for its great mobility include the drives for the musculoskeletal system. Therefore, smart, lightweight and high-performance joints were developed with a focus on energy efficiency.

Save energy with a secure hold

There is also one in the robot's upper body Joint: If the Space Climber runs into a sloping wall such as a crater, the upper body can adapt to the surroundings and stand upright or fold down on the edge of the crater.

There is also one in the robot's upper body Joint: If the Space Climber runs into a sloping wall such as a crater, the upper body can adapt to the surroundings and stand upright or fold down on the edge of the crater.

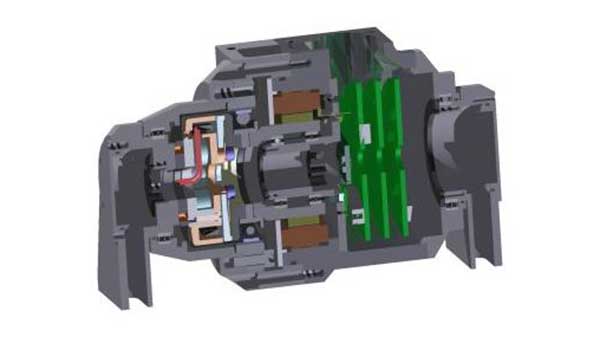

In addition, the upper body also stands up, for example, in order to have the front legs free for manipulation. This joint is extremely compact Roba stop safety brake installed, which the drive specialist developed specifically for this application.

If the Space Climber runs with the upper body horizontal in a straight plane, the brake reliably holds the joint in position and prevents the input and output from twisting when the engine is switched off. “With this brake, the joint does not have to be permanently energized to maintain its position. This saves energy,” explains DFKI project manager Dr.-Ing. Sebastian Bartsch.

The brake has a holding torque of 0,28 Nm and weighs only 40,5 g with an outer diameter of 120 mm. “The small dimensions of the brake were crucial for us,” says Dr.-Ing. Bartsch. “We only had a very limited space available in which to accommodate the brake without changing the design or significantly increasing the weight.”

The Spring-applied brakes work according to the fail-safe principle, so they are closed when there is no energy. The brakes generate the braking force using compression springs. After the power is switched off or in the event of a power failure, they ensure that the devices are held reliably and securely in any position.

Robot lady Aila with memory

Also in the robot system aila, a mobile, autonomous system with two arms, the mini brake has already been used. “With Aila, the brake was in the elbow joint,” explains the project manager. “If the robot picks up something, energy would have to be constantly applied to keep the arm and object up. The brake can be used to switch off the engine, thereby saving energy.”

Devices for braking energy recuperation for electric drives

Devices for braking energy recuperation for electric drives

The robot lady can sort and individually handle heterogeneous objects that differ greatly in shape and properties, such as different items from the supermarket. With the help of the digital memory Using the stored object information, it adapts its gripping and transport behavior to the specific characteristics of the objects.

Brakes proven millions of times in the field

The Allgäu drive specialists have been developing and manufacturing spring-operated safety brakes for over 40 years and are the global leader in brakes for passenger elevators, stage equipment and vertical axes. The company also has the expertise to provide customized and economical solutions for customer-specific requirements, e.g. B. for Medical Technology or Roboticto develop applications. Their safety brakes have already proven their high reliability millions of times in field use. Proven design principles and permanent checks on calibrated test benches ensure consistently high quality.

You might also be interested in...

High-performance brake wind turbine with monitoring

Robco robot kit with safety brake from the construction kit

Predictive maintenance for clutches and brakes

Shaft coupling without play, precise and smart

Compensating coupling | For axial, radial and angular offset

Mayr drive technology | Inventor of the freedom to play

Simone Dauer is a press officer at Chr. Mayr GmbH + Co. KG, Mauerstetten