Hainbuch expands automation with Vischer & Bolli takeover

- Details

- Hits: 4825

The hornbeam GmbH from Marbach am Neckar took over the company on October 1st, 2020 Vischer & Bolli Automation in Lindau taken over. With that he builds Workholding Specialist is continuing to expand its expertise in the field of automation. In the future, he will also be able to offer his customers complete automation solutions.

Vischer & Bolli Automation has been successful in the market with automation solutions for 15 years. For several years now, the company has also acted as a general contractor. In addition to special solutions in the stationary sector, the focus and know-how are on automation. Customers receive all from a single source from clamping device, via robot cell, assembly device, grab, Storage up to software and sensors.

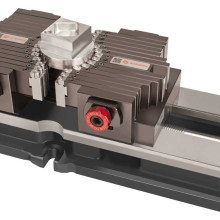

Vacuum clamping technology for workpieces with complex contours

Vacuum clamping technology for workpieces with complex contours

"Anyone who wants to produce economically in Germany in the future will not be able to avoid the automation of small batch sizes. We are now not only offering the solution for the clamping device and the interface for the automated clamping device change, but everything from a single source, virtually all-round carefree -Package to "commented Sylvia Rall, managing partner of Hainbuch, for whom a new chapter in automation begins with the purchase of Vischer & Bolli.

"Anyone who wants to produce economically in Germany in the future will not be able to avoid the automation of small batch sizes. We are now not only offering the solution for the clamping device and the interface for the automated clamping device change, but everything from a single source, virtually all-round carefree -Package to "commented Sylvia Rall, managing partner of Hainbuch, for whom a new chapter in automation begins with the purchase of Vischer & Bolli.

Hainbuch combines digitization and automation

For years, Hainbuch has been developing products and solutions with which clamping heads, stops and clamping devices can be changed automatically. The two future fields Automation and digitization the company is consistently building up and expanding. The acquisition of Vischer & Bolli Automation is the perfect complement.

"We are very pleased to be able to offer complete solutions for automation and clamping technology together with Hainbuch", is also pleased Marcel Haltiner, Managing Director of Vischer & Bolli Automation.

Who is Hainbuch?

Hainbuch is a developer and manufacturer of high-precision clamping solutions for clamping workpieces during turning, milling and grinding on machine tools. The international marketing of the products takes place through our own sales force, 13 subsidiaries and around 40 commercial agencies worldwide.

You might also be interested in...

clamping technology | Intelligent, safe, efficient!