Bearingless and high resolution rotary encoder for large shafts

- Details

- Hits: 10353

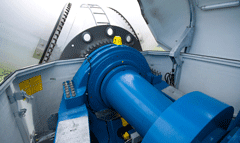

The "HD mag flex" strap encoder from Baumer eThanks to its new concept, it enables direct, precise angle and speed measurement on large shafts. The flexible, magnetic precision scale is manufactured to match the shaft diameter and rolled up to save space for transport. In use, it can be fixed like a belt with the turnbuckle on the circumference of the shaft.

The shaft remains mounted, eliminating the cost and time required for mechanical adjustments and complex assembly. Intelligent real-time signal processing and the bearing-free, contact-free design make the rotary encoder ideal for applications on generators, large drives or in water and wind power plants.

The tension band encoders HDmag flex MIR 3000F and MQR 3000F are a revolutionary and particularly economical solution for the precise position and speed measurement on shafts with large diameters. The precise measurement of position and speed is required for precise and energy-efficient control of drives and generators. Encoders provide the necessary information: The larger the shaft diameter of a drive or generator, the more difficult it is to manufacture and assemble the encoders; So far, there have only been cost-intensive special versions above 1 m in diameter. Now there is a new solution for this: A bearingless magnetic tape encoder can be manufactured for shafts of practically any size and enables precise, high-resolution measurement of position and speed. It is based on contactless and wear-free magnetic scanning combined with sophisticated signal processing.

The precise measurement of position and speed is required for precise and energy-efficient control of drives and generators. Encoders provide the necessary information: The larger the shaft diameter of a drive or generator, the more difficult it is to manufacture and assemble the encoders; So far, there have only been cost-intensive special versions above 1 m in diameter. Now there is a new solution for this: A bearingless magnetic tape encoder can be manufactured for shafts of practically any size and enables precise, high-resolution measurement of position and speed. It is based on contactless and wear-free magnetic scanning combined with sophisticated signal processing.

Sensor technology protects WKA rotor blades from ice and damage

Sensor technology protects WKA rotor blades from ice and damage

The measurement of position and speed on large motor or generator shafts, such as those found in rolling mills, paper machines, wind and hydropower plants, has hitherto meant considerable effort. On the one hand, the rather harsh environmental conditions require the most robust encoder solutions possible, and on the other hand, it is by no means trivial to mount a corresponding encoder on the thick shafts.

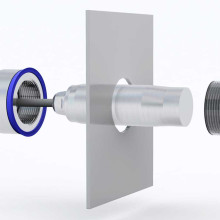

Big waves required compromises

The assembly of a standard heavy-duty encoder requires a small adapter pin on the free shaft end. This can result in significant run-out errors in the form of wobble and the encoder may not measure on the load side that is more interesting from a control point of view. Its B-side mounting also prevents a continuous hollow shaft that is useful for many applications and at the same time increases the overall installation space required. A mechanical step protection for the encoder is usually also required to protect it from damage.

The assembly of a standard heavy-duty encoder requires a small adapter pin on the free shaft end. This can result in significant run-out errors in the form of wobble and the encoder may not measure on the load side that is more interesting from a control point of view. Its B-side mounting also prevents a continuous hollow shaft that is useful for many applications and at the same time increases the overall installation space required. A mechanical step protection for the encoder is usually also required to protect it from damage.

A better alternative are magnetic rotary encoders without bearings, which consist of a pole wheel mounted on the shaft and a fixed scanning head. They can also be installed on the A side, as these encoders are very short. With large shaft diameters - currently around 1000 mm are possible - this can still be difficult because the encoder wheel, which has to be pushed over one shaft end and fixed, is quite large and heavy.

There are now split pole wheels on the market for retrofitting to shafts without a directly accessible end. However, these are associated with two serious disadvantages: There are high costs and restrictions with regard to the available hollow shaft diameters, because these are still custom-made products that match the diameter. In addition, the two joints at the ends of the half-rings lead to a loss of signal quality.

Stretched around the shaft with precise measuring standard

Against this background, users from the areas of wind and hydropower plants, paper machines, construction machinery or large drives are pushing for better solutions. Your need for robust, easily assembled and exchangeable bearingless encoder systems with which speed and position can be measured with high resolution is constantly increasing. The sensor specialist Baumer has now reacted accordingly: With a new, patent-pending and consistently thought-out approach, the HD mag flex tensioning tape encoder now solves such demanding measuring tasks on shafts with any and theoretically unlimited diameter.

Against this background, users from the areas of wind and hydropower plants, paper machines, construction machinery or large drives are pushing for better solutions. Your need for robust, easily assembled and exchangeable bearingless encoder systems with which speed and position can be measured with high resolution is constantly increasing. The sensor specialist Baumer has now reacted accordingly: With a new, patent-pending and consistently thought-out approach, the HD mag flex tensioning tape encoder now solves such demanding measuring tasks on shafts with any and theoretically unlimited diameter.

The tensioner is based on a double magnetic scan of a tape that is tensioned around the shaft at its ends like a belt with a turnbuckle. Thanks to the non-contact measuring principle, the encoder works practically without wear and is extremely insensitive to dust, dirt, liquids and condensation. The sensor head with fully encapsulated electronics can be attached to the shaft in any position and tolerates large axial displacements of the clamping band of ± 5 mm, such as can occur due to thermal expansion on long shafts. The radial distance from the clamping band to the sensor head, i.e. air gap, can be up to 3 mm, which means that the tolerances typical of large shafts and their bearings can be easily mastered.

Simple and quick installation

The tensioning strap can be attached to any axial position on the shaft quickly and easily. The shaft surface remains free of holes, grooves and punctures. Instead, the tensioning strap, which is factory-tailored to the circumference of the shaft, can simply be placed around the shaft and connected to the turnbuckle attached to its ends. The encoders are therefore very well suited for retrofitting.

The tensioning strap can be attached to any axial position on the shaft quickly and easily. The shaft surface remains free of holes, grooves and punctures. Instead, the tensioning strap, which is factory-tailored to the circumference of the shaft, can simply be placed around the shaft and connected to the turnbuckle attached to its ends. The encoders are therefore very well suited for retrofitting.

The turnbuckle is designed so that it can compensate for tolerances of the shaft diameter of about 2 mm. The subsequent assembly of the sensor head only requires two fastening screws. The air gap can be easily adjusted with a gauge. One person can do this in a matter of minutes. The electronic function monitoring integrated in the scanning head can be used as an adjustment aid. Even a sensor version designed for a shaft diameter of 2 m weighs less than 2 kg and fits in a shoe box-sized packaging. Assembly and transport costs are thus significantly reduced compared to the solutions previously available.

Fast signal processing for high-precision measurements

Thanks to its intelligent real-time signal processing, the tension band encoder delivers incremental and quasi-absolute position signals at a consistently high quality, regardless of the tension lock width. Up to 131.072 pulses per revolution are possible for each shaft diameter. The two sensors in the scanning head are factory-set so that at least one magnetic sensor always scans the magnetized tape. This enables a continuous position and speed calculation despite the gap caused by the turnbuckle. The shaft can move back and forth axially up to 10 mm and radially up to 2 mm.

Thanks to its intelligent real-time signal processing, the tension band encoder delivers incremental and quasi-absolute position signals at a consistently high quality, regardless of the tension lock width. Up to 131.072 pulses per revolution are possible for each shaft diameter. The two sensors in the scanning head are factory-set so that at least one magnetic sensor always scans the magnetized tape. This enables a continuous position and speed calculation despite the gap caused by the turnbuckle. The shaft can move back and forth axially up to 10 mm and radially up to 2 mm.

The accuracy of the position signal, which has a resolution of up to 20 bits, is ± 1000 degrees on a 0,02 mm shaft. This enables, for example, the remote-controlled rotor lock of the turbine shaft on wind turbines. The tension band encoder delivers a valid position as soon as the gap of the tension band has passed the scanning head twice in the same direction of rotation after switching on the device.

Couplings, brakes and monitoring for the wind turbine

Couplings, brakes and monitoring for the wind turbine

At the same time, the tension band encoder delivers precise digital speed signals in real time up to 18 bits with freely selectable filtering. It records creeping movements of just 0,003 min-1, This corresponds to one revolution in 6 hours. The output signals required by the application are configured at the factory. SSI, HTL, TTL SinCos and combinations thereof are available as electrical interfaces.

HD likes flex: The rotary encoder for rolling up

You might also be interested in...

encoders | Industrial Ethernet and Industry 4.0 encoders

Ultrasonic sensor | For distance, distance and level

Pressure sensors | Pressure measurement technology goes digital

Baumer Group builds new innovation center in Frauenfeld

Rotary encoders for axes in drives, machines and systems