Formed thin-section bearings made of drawn steel

- Details

- Hits: 13682

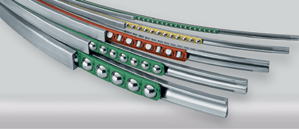

With the non-cutting thin section bearings CSX, Schaeffler Group Industrial is launching a new bearing type with special properties: The bearing rings are no longer manufactured conventionally, but are bent from drawn, stainless steel profiles. This gives them good protection against corrosion and is resistant to many media.

With the non-cutting thin section bearings CSX, Schaeffler Group Industrial is launching a new bearing type with special properties: The bearing rings are no longer manufactured conventionally, but are bent from drawn, stainless steel profiles. This gives them good protection against corrosion and is resistant to many media.

The common feature of all chipless thin-section bearings are the large diameters with a small cross-section - this saves space. The dynamic and static load capacities reach those of a solid bearing made of bearing steel 100Cr6. Due to the many rolling elements and the large pressure angle, the bearings are characterized by high rigidity.

The manufacturing concept enables very short delivery times - even for intermediate sizes outside the rows. The high performance and the good properties of the new product family have already been proven in applications in medical technology, for example in operating tables or for swiveling X-ray cameras.

CSX chipless thin-section bearings are available as four-point bearings open on both sides with 45 ° contact angle in five cross sections and as cross-roller bearings. The four-point contact can accommodate combined loads. The thin ring bearings can be used at temperatures from -40 ° to + 120 ° C. The bearing rings and cages are slotted, so that the expansions of different materials can be compensated. In addition, users have free choice of material (eg aluminum) in the surrounding construction. Further advantages of the new chipless thin-section bearings are the simple, quick and cost-saving assembly and disassembly, since no special tools are required.

The cages are made of plastic Pa12, alternatively of PEEK. As with a traffic light, the colors of the cages signal the bearing play: red cage stands for pretension, green cage marks the normal game, yellow cage an increased bearing play.

There are two options for bearing mounting: clamped on one or both sides. If the chipless thin-section bearing is to be installed clamped on one side, a shaft or housing shoulder is required. After the bearing has been pushed onto the shoulder, it is secured to the outer or inner ring with a washer. For the two-sided braced mounting housing and shaft must have a paragraph. The bearing is then pushed onto the heels and secured to both the outer and the inner ring with a washer. The product family is also used in other applications and industries.

You might also be interested in...

Profile rail guide using modern foundry technology from Laempe

Artificial Intelligence | trends and developments

Planetary gear + strain wave gear precision from Schaeffler

spindle bearing | The Vacrodur high-performance elements

linear guide | Precise, light, durable