High-strength lightweight steel for chassis applications

- Details

- Hits: 4609

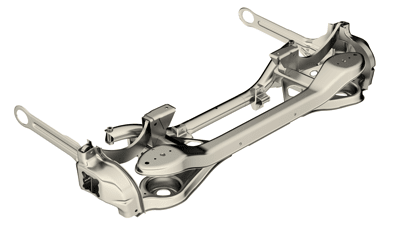

Tata Steel has developed a new steel grade specifically for the chassis and suspension area: The HR CP800-UC is a hot-rolled, advanced high-strength complex-phase steel. This combines the high strength required for the special performance requirements with good formability, with which complex shaped chassis components can be manufactured. The new development is based on a customer requirement for a steel that is both high-strength and malleable and at the same time saves weight in the chassis.

Tata Steel has developed a new steel grade specifically for the chassis and suspension area: The HR CP800-UC is a hot-rolled, advanced high-strength complex-phase steel. This combines the high strength required for the special performance requirements with good formability, with which complex shaped chassis components can be manufactured. The new development is based on a customer requirement for a steel that is both high-strength and malleable and at the same time saves weight in the chassis. Typical chassis and suspension components that require particularly high strength are lower control arms, trailing arms and torsion-beam. In addition to the fatigue resistance in the normal load cases - such as the burden of a wheel by a pothole - these components must be designed increasing weight-optimized to meet increasingly stringent EU emissions limits. Therefore, advanced high strength steels (AHSS) usually come here next high-strength (HSS) is used. In conventional HSS steels, however, deteriorated at a higher strength of their formability, which leads to problems in the production of complex-shaped chassis components. The HR CP800-UC is a multi-phase steel from the AHSS family, can be worked better. The steel can be especially stretched further without it shatters or breaks - at the same strength.

Kettcar for adults creates a range of up to 200 km

Kettcar for adults creates a range of up to 200 km

The fine-grained matrix bainitic microstructure of the new type of steel increases the fatigue resistance and leads to a high tensile strength of about 800 MPa and a high yield strength, which ensures a uniform strength of the final component. HR CP800-UC meets both the specifications of euro standard (HCT780C) and the VDA (HR660Y760T-CP) and thus the high safety requirements of vehicle manufacturers worldwide. The light-weight steel chassis, there are first in dimensions of 2,5 4,7 to mm thickness and a width of up to 1650 mm. In the coming months, the dimension of the window is further increased.