Polypropylene Polyamide replaced with suction tubes

- Details

- Hits: 10942

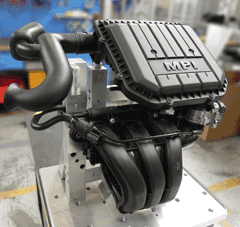

With polypropylene (PP) intake manifolds, Röchling Automotive is setting new benchmarks in terms of costs, weight and acoustics. The 3 criteria improve due to the low density of polypropylene compared to polyamide (PA), the most common material for intake manifolds to date. At the same time, the resilience is sufficient. References in Brazil and Europe are the 1-litre three-cylinder and in China the 1,6-litre four-cylinder petrol engine from VW.

With polypropylene (PP) intake manifolds, Röchling Automotive is setting new benchmarks in terms of costs, weight and acoustics. The 3 criteria improve due to the low density of polypropylene compared to polyamide (PA), the most common material for intake manifolds to date. At the same time, the resilience is sufficient. References in Brazil and Europe are the 1-litre three-cylinder and in China the 1,6-litre four-cylinder petrol engine from VW.

"The PP intake manifold is the first and only of its kind in China and Brazil. In Europe, it is the first three-cylinder application. This is acoustically very sophisticated, "said Marco Barbolini, product manager for the Luftansaugstrecke at Röchling Automotive. "That's a total first Saugrohranwendungen with polypropylene at Röchling. For substitution of polyamide were to face various challenges. For this we were rewarded with an improved acoustics. "

Less energy-intensive production of PP

Fewer processing steps and the lower melt temperature and density allow 15% cost advantage over PA. In addition, PP is readily available worldwide. "We have in each of the target markets found a PP local suppliers," says Barbolini. Since PP does not have dried and the mold and melt temperatures are lower, the production of the components is less energy intensive. This improves not least the CO2Footprint.

Fewer processing steps and the lower melt temperature and density allow 15% cost advantage over PA. In addition, PP is readily available worldwide. "We have in each of the target markets found a PP local suppliers," says Barbolini. Since PP does not have dried and the mold and melt temperatures are lower, the production of the components is less energy intensive. This improves not least the CO2Footprint.

Despite the lower processing temperature of providers achieved with PP now almost the same continuous operating temperature of 120 ° C as with PA. However, this requires a special thermal stabilization, mainly because of the critical resistance to hot air. "This is our special expertise," says Barbolini. At room temperature and low temperatures PP and PA, however, have the same stiffness.

The weight advantage of 15% from PA nor harm in tensile strength and elongation at break with it. The most important mechanical properties are sufficient for the request, even if they are not always equal to those of polyamide. Also in chemical resistance polypropylene is stable. When ethanol is compared to polyamide even superior. The same applies with regard to the absorption of moisture.

The sound radiation improves over PA also due to lower density - according to VW "measurable and audible." Particularly at higher speeds and frequencies. Here is the sound pressure to back up 10 15 dB. This superior acoustic comfort was ultimately the reason for the substitution of PA by PP. The geometry of the suction had to be adapted to only marginal, to compensate for the strength values for the new material.

Special consideration and sound design: air filter box

Röchling has performed the complete customization and development involved in the sound design, the entire intake path with special consideration of the air filter box. Fortunately, the acoustic effects of different forms of attachment points, decoupling elements Luftftiltergehäusedeckel and floors, and Saugrohrplenum Drosselklappenflansch be simulated. The agreement between calculation and measurement was satisfactory. Geometry, material, density and sealing of the filter itself also affect the acoustics. It has benefited the acousticians that the air filter comes with its dampening effect of the in-house development and manufacturing. Thus, the acoustics of the complete module from the intake manifold and air filter box can be optimized as a system.

Röchling has performed the complete customization and development involved in the sound design, the entire intake path with special consideration of the air filter box. Fortunately, the acoustic effects of different forms of attachment points, decoupling elements Luftftiltergehäusedeckel and floors, and Saugrohrplenum Drosselklappenflansch be simulated. The agreement between calculation and measurement was satisfactory. Geometry, material, density and sealing of the filter itself also affect the acoustics. It has benefited the acousticians that the air filter comes with its dampening effect of the in-house development and manufacturing. Thus, the acoustics of the complete module from the intake manifold and air filter box can be optimized as a system.