Brushes against marten bites and as versatile helpers in the automobile

- Details

- Hits: 25644

Technical brushes are becoming increasingly important in the automotive and commercial vehicle industry: In the vehicles themselves, Mink fiber solutions are used as privacy screens, dirt seals, to cover the convertible top mechanism or as safety accessories against marten bites. In automotive production, the versatile brushes have also become irreplaceable helpers in many areas.

Technical brushes are becoming increasingly important in the automotive and commercial vehicle industry: In the vehicles themselves, Mink fiber solutions are used as privacy screens, dirt seals, to cover the convertible top mechanism or as safety accessories against marten bites. In automotive production, the versatile brushes have also become irreplaceable helpers in many areas.

Whether cleaning and sealing, transporting, carrying or fixing sensitive components or deburring aluminum rims - technical brushes are as versatile as their wide range of variants. Even paintwork is no longer imaginable without technical brushes: Huge, swiveling ostrich feather rollers ensure an absolutely dust-free body surface before painting.

No chance for marten bites

The brush curtain against marten bites, however, is probably the most sensible invention for the consumer. Battles under the bonnet, battered cables and rubber hoses are a thing of the past. About 160.000 times a year - preferably at night in spring and late summer - beat the predators in Germany and cause damage in the millions.

Kettcar for adults creates a range of up to 200 km

Kettcar for adults creates a range of up to 200 km

Mink Brushes has developed an optimal mechanical marten protection in close cooperation with VW. Already in experiments in marten breeding facilities, the Mink fiber technology has proven to be highly resistant to martens. Brush curtains mounted in the front wheel arches reliably prevent the animals from entering. The device thus prevents bites in brake lines, coolant hoses, ignition cables and engine mats.

Ostrich feather blades keep body surfaces clean

The gentle and fast dedusting or cleaning of workpieces is an essential part of quality assurance in modern manufacturing processes. In the automotive industry, the particular challenge is to get the body surfaces completely dust-free before the top coat. The dedusting is made more difficult by electrostatic charging, through which the dust particles formally stick to the body. Another difficulty is not to leave the slightest trace of scratching or scratches on the highly sensitive basecoat.

The gentle and fast dedusting or cleaning of workpieces is an essential part of quality assurance in modern manufacturing processes. In the automotive industry, the particular challenge is to get the body surfaces completely dust-free before the top coat. The dedusting is made more difficult by electrostatic charging, through which the dust particles formally stick to the body. Another difficulty is not to leave the slightest trace of scratching or scratches on the highly sensitive basecoat.

After many trials and intensive development work, the brush specialist remembered a tried-and-tested principle - the dust duster. In the search for the optimal material, the choice fell on a natural product: the ostrich feather, which can not be surpassed due to its fine branching and softness as the finest dedusting element. Due to its own electrostatic charge, the ostrich feather "absorbs" the dust from the surface to be processed and releases it only by means of appropriate extraction or cleaning.

Similar to car washes, ostrich feather blades are used as huge rotor brushes in dedusting systems. The springs, which are sourced from South Africa, also withstand extreme abrasion: Since the primed car bodies have neither glazing nor lining on the front and rear during painting, the ostrich feathers are sometimes exposed to razor-sharp edges during the dedusting process. Incidentally, the animals are killed for their meat, not their feathers.

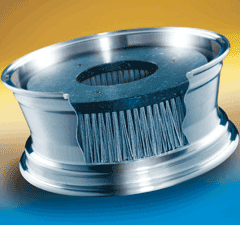

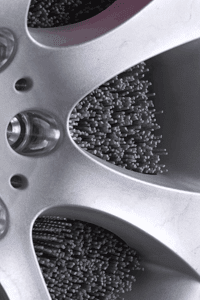

Sharp edges quickly deburred

Technical brushes have also become an indispensable tool in the manufacture of aluminum rims in the automotive industry. Reducing costs, or even better avoiding them altogether, is a daily challenge in this industry. When processing alloy wheels before painting, there is the problem of burr formation on the cast and then machined wheels. With disc and round brushes, bristled with abrasive fibers, the sharp edges of the aluminum rims are deburred and rounded reliably, quickly, very economically and yet gently. The grinding effect results from the hard and sharp tips of the silicon carbide grinding material, which is enclosed in the plastic fibres. When machining workpieces, wear and tear on the polyamides A certain amount of the abrasive is always released and is therefore used in a way that is gentle on the material. These properties enable the abrasive fibers to smooth, deburr or round surfaces and edges, precisely following the contours of a workpiece.

Technical brushes have also become an indispensable tool in the manufacture of aluminum rims in the automotive industry. Reducing costs, or even better avoiding them altogether, is a daily challenge in this industry. When processing alloy wheels before painting, there is the problem of burr formation on the cast and then machined wheels. With disc and round brushes, bristled with abrasive fibers, the sharp edges of the aluminum rims are deburred and rounded reliably, quickly, very economically and yet gently. The grinding effect results from the hard and sharp tips of the silicon carbide grinding material, which is enclosed in the plastic fibres. When machining workpieces, wear and tear on the polyamides A certain amount of the abrasive is always released and is therefore used in a way that is gentle on the material. These properties enable the abrasive fibers to smooth, deburr or round surfaces and edges, precisely following the contours of a workpiece.

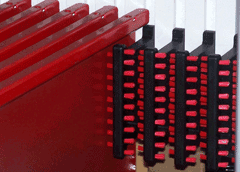

Centipede principle for the floating transport of sensitive components

For a surface-sparing transport of sensitive components, Göppinger has developed flexible and economical transport solutions for international world market leaders using fiber technology.

Highly sensitive components, flexible logistics and zero tolerance are part of the everyday life of many companies. Often, the slightest scratch directly means complete rejects. Fenders, roofs or entire side parts of vehicles are transported over long distances in steel load carriers. Transport locks made of styrofoam, foam or rubber have significant weaknesses: The fixings are only moderately flexible and embedded dirt particles can damage the delicate surfaces of the cargo. Mink fiber technology, with its high flexibility and great variability, is an efficient alternative to conventional transport safety devices. Thousands of fibers ensure optimum adaptation to the transported goods and their degree of holding can be varied almost arbitrarily by fiber density, length and diameter.

Dirt particles fall between the fiber bundles and due to the punctual support on many fine fibers, which allow an almost "floating" transport, the friction coefficients can be reduced to a minimum compared to the full-surface edition. Scratches, dulling and shiny spots on the surfaces are reliably prevented. The elastic tolerance ranges of the technical brushes allow the use for different model types of the automobile manufacturers and thus save expensive and time-consuming adjustments. The installation is also extremely cost-effective and can be easily integrated into existing transport constructions.

Dirt particles fall between the fiber bundles and due to the punctual support on many fine fibers, which allow an almost "floating" transport, the friction coefficients can be reduced to a minimum compared to the full-surface edition. Scratches, dulling and shiny spots on the surfaces are reliably prevented. The elastic tolerance ranges of the technical brushes allow the use for different model types of the automobile manufacturers and thus save expensive and time-consuming adjustments. The installation is also extremely cost-effective and can be easily integrated into existing transport constructions.

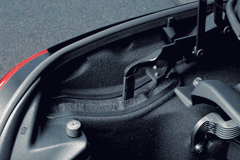

Everything tight - even in the convertible

Technical brushes have also been proven in applications such as privacy screens, dirt seals, gearshift and pedal seals, and radiator and engine compartment seals for more efficient cooling performance. A current example of the use of such fiber solutions can be found in the Mercedes SLK Convertible, where the function passage for the top mechanism is protected by means of technical brushes. Thus, the flexible fibers are not only for the optical cover of the convertible top mechanism, they also prevent reaching in and thus possible injuries. The wavy fiber design as well as the brush with different density, fiber height and fiber thickness allow an ideal adaptation depending on the place of use. Not only do the fibers prove to be extremely flexible: the in-house injection molding department also allows the brush body to be adapted to specific requirements in terms of shape and geometry. In combination with the large selection of fibers, an optimal seal against dirt and other particles can be realized.

Technical brushes have also been proven in applications such as privacy screens, dirt seals, gearshift and pedal seals, and radiator and engine compartment seals for more efficient cooling performance. A current example of the use of such fiber solutions can be found in the Mercedes SLK Convertible, where the function passage for the top mechanism is protected by means of technical brushes. Thus, the flexible fibers are not only for the optical cover of the convertible top mechanism, they also prevent reaching in and thus possible injuries. The wavy fiber design as well as the brush with different density, fiber height and fiber thickness allow an ideal adaptation depending on the place of use. Not only do the fibers prove to be extremely flexible: the in-house injection molding department also allows the brush body to be adapted to specific requirements in terms of shape and geometry. In combination with the large selection of fibers, an optimal seal against dirt and other particles can be realized.