Heizkat should solve future emissions problems

- Details

- Hits: 26926

Hybrid vehicles, electric vehicles with combustion engine as range extender, state-of-the-art diesel engines and direct-injection gasoline engines all share a decline in exhaust gas temperatures. These modern vehicle and engine concepts will not be able to avoid using the electrically heated catalytic converter in the future.

Hybrid vehicles, electric vehicles with combustion engine as range extender, state-of-the-art diesel engines and direct-injection gasoline engines all share a decline in exhaust gas temperatures. These modern vehicle and engine concepts will not be able to avoid using the electrically heated catalytic converter in the future.

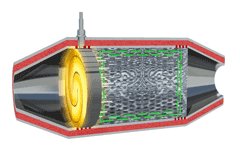

Automatic start-stop systems, regular interval operation of compact combustion engines or the more effective conversion of combustion energy into mechanical drive power ensure that the catalytic converter often falls below the light-off temperature. Thanks to the freely selectable heating cat, emissions can be drastically reduced, both in the start-up phase and during ongoing (interval) operation.

In the mid-90s, Emitec and the German automotive industry had developed the "Emicat" ready for series production. As the world's first and to this day only catalyst manufacturer, the Rhinelander were able to introduce an electrically heated catalyst into series production back then. The innovative technology was initially used by Alpina in its Alpina B12 5,7 model. Shortly afterwards, BMW followed suit with the series application in the BMW 12-cylinder. Both manufacturers were able to significantly fall below the 1996 emission limit values in Europe, Japan and the USA. Of course, the Emicat has been continuously developed to this day, so that it is immediately ready for future applications.

Use fuel more effectively and reduce raw emissions

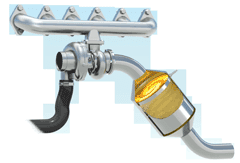

Above all, a comparison between the "in-engine catalyst heating measures" that are often common today and the electrically heated catalyst is very positive in favor of the Emicat. The reason for this is the more effective use of fuel and the reduction of raw emissions. The heating cat is located directly in front of the main catalytic converter. Longer distances and thus heating losses are avoided. Up to 65% in fuel and thus CO2 emissions can be saved when using the Emicat in individual operating points.

Above all, a comparison between the "in-engine catalyst heating measures" that are often common today and the electrically heated catalyst is very positive in favor of the Emicat. The reason for this is the more effective use of fuel and the reduction of raw emissions. The heating cat is located directly in front of the main catalytic converter. Longer distances and thus heating losses are avoided. Up to 65% in fuel and thus CO2 emissions can be saved when using the Emicat in individual operating points.

The additional costs of the heating cat can be overcompensated. Thanks to the higher effectiveness of the system consisting of heating cat and downstream main cat, the cat volume and thus the precious metal loads can be significantly reduced. The on-board electrical system of modern vehicles - with their innovative electrics and, if necessary, recuperation such as energy recovery when braking - is hardly burdened by using the Emicat. Due to the recent development of a thermoelectric generator (TEG), there is even an excess of electrical energy. The E-Kat therefore offers the option of converting the generator's energy, which is available in a CO2-neutral manner, into usable heat during the overrun phases. The combination of the heatable catalytic converter with automatic start-up systems is particularly advantageous, since in this way the cooling of the catalytic converter and therefore the in-engine, fuel-consuming heating can be avoided in the idling phases.

Avoid motorized Kat heating in gasoline engines

Gasoline engines are known to emit very small, mostly invisible particles. Direct-injection Otto engines increasingly emit such particles in the cold-start phase. This is because additional fuel is burned in the engine to heat up the catalytic converter system more quickly. This motorized catalytic converter heating can be avoided with the heating catalytic converter, which also significantly reduces soot emissions. At the same time, the improvement in pollutant emissions has the advantage that a significant fuel consumption advantage is achieved.

Kettcar for adults creates a range of up to 200 km

Kettcar for adults creates a range of up to 200 km

In SCR systems, on the other hand, the Emicat is able to optimally vaporize the injected urea, thereby increasing the SCR catalytic converter effectiveness. These heated metal catalytic converters, operated with an electrical output of 1 to 3 kW, not only increase the working temperature in cars by up to 100 °C (in commercial vehicles by a decisive 20 to 30 °C), but also by injecting the Adblue urea solution on the hot E-Kat, a significantly earlier start of the NOx conversion is achieved. In diesel vehicles, the electrically heated catalytic converter from Lohmar will become indispensable thanks to stricter exhaust gas limits in the future.